In modern industrial production, the packaging and transportation of steel coils is a vital link. With the rapid development of the global steel industry, the demand for steel coil packing lines is increasing. This article KINGREAL SLITTING will comprehensively discuss the functions, roles and needs of steel coil packaging machines in various countries.

1. Brief Introduction of Steel Coil Packing Machines

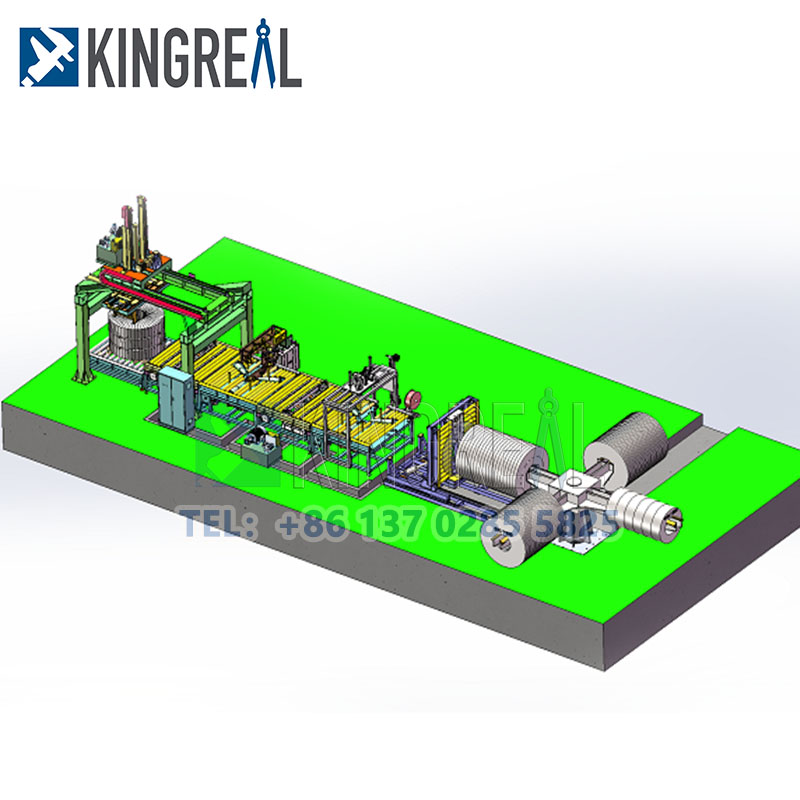

KINGREAL SLITTING steel coil packing line is an efficient integrated equipment specially designed for the handling, packaging and stacking of steel coils. With the rapid development of industrial automation, traditional manual handling and packaging methods are gradually replaced by modern steel coil packaging machines. The design concept of KINGREAL SLITTING steel coil packing line is to simplify the entire steel coil production and warehousing process through intelligent equipment integration, thereby significantly improving production efficiency.

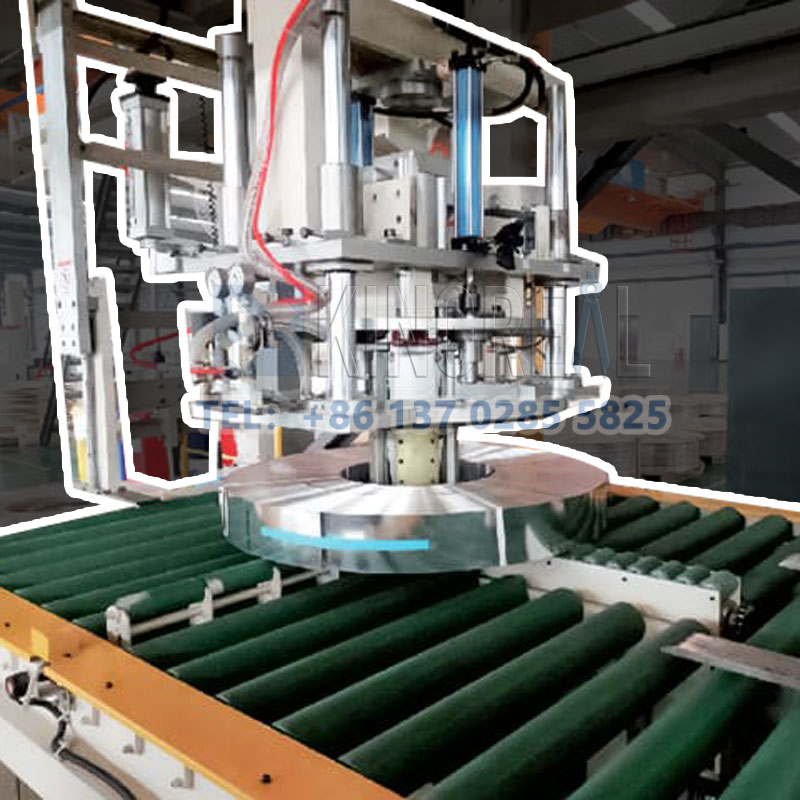

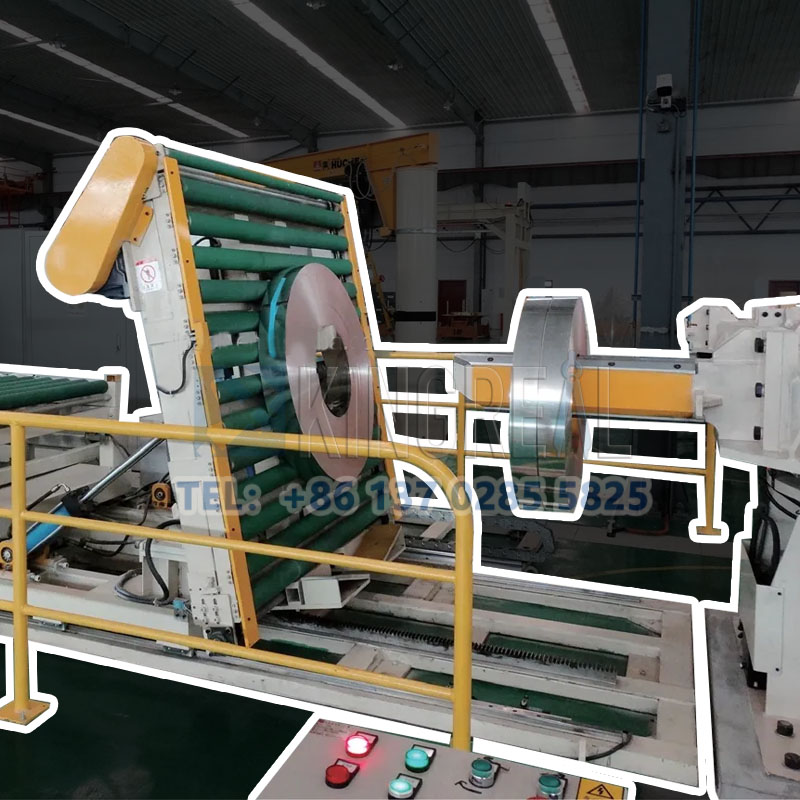

The steel coil packaging machine integrates a variety of key equipment, including steel coil handling machines, steel coil trolleys, packaging machines, bundling units and stackers. The collaboration between these equipment enables each link to operate efficiently. For example, the coil handling machine is responsible for moving the coils on the production line to the designated location, while the coil trolley can easily and flexibly operate in the workshop to ensure that the coils can quickly reach the next processing or packaging link. The steel coil packing machine is responsible for properly packaging the coils to ensure that they are not damaged during transportation and storage.

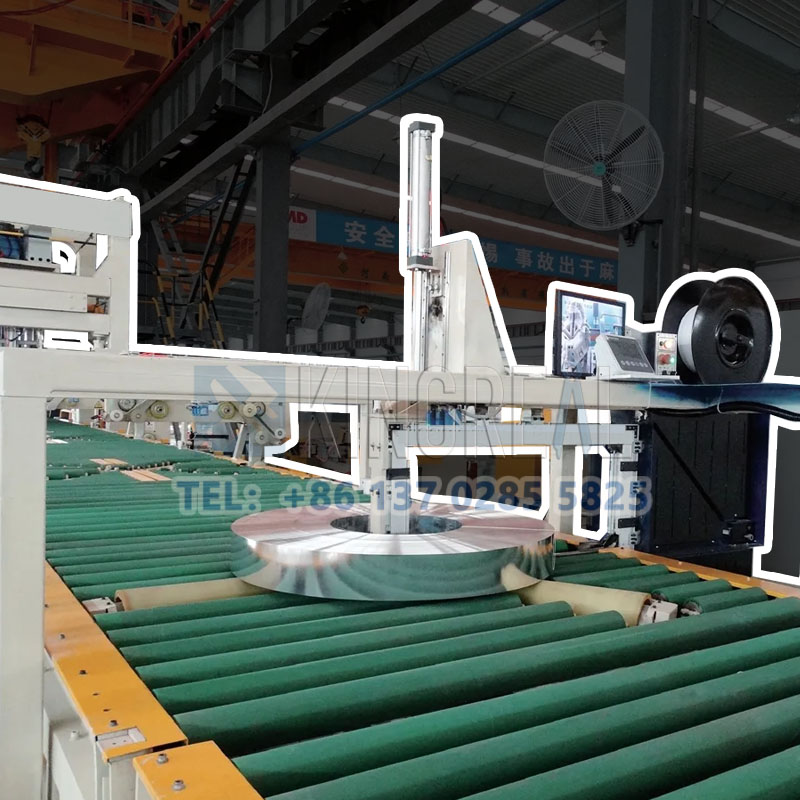

The introduction of the strapping unit has improved the overall efficiency of the steel coil packing line. It can not only strap the coils quickly and accurately, but also ensure the firmness of the strapping and reduce the material loss caused by improper strapping. The stacker is responsible for neatly stacking the packaged coils in the warehouse to maximize the use of storage space. The integration of this series of equipment truly simplifies the entire process from longitudinal shearing coil production to warehousing, providing enterprises with a complete solution.

In addition, the use of the steel coil packaging machine with the aluminum slitter makes the entire production process more efficient. The aluminum slitter is responsible for cutting large coils into small coils, while the steel coil packing machine is immediately packaged after cutting, ensuring a seamless connection from raw material processing to finished product packaging. This close cooperation not only improves production efficiency, but also reduces waiting time in the production process, allowing enterprises to respond to market demand more quickly.

2. Role of the Steel Coil Packing Line

2.1 Automation

One of the biggest features of the steel coil packaging machine is high automation. Traditional manual packaging is not only inefficient, but also requires a lot of human resources. The introduction of automated equipment allows the packaging process of steel coils to be unattended, reducing manual intervention and improving overall production efficiency. Through the intelligent control system, the steel coil packing machine can monitor the production status in real time and adjust the operating parameters in time to ensure the stability of packaging quality.

2.2 Fast packaging speed

In modern manufacturing, time is money. The design of the steel coil packing line fully considers this and has the ability to package quickly. Compared with manual operation, the automated steel coil packing machine can complete more packaging tasks in a shorter time. According to different production needs, the steel coil packaging machine can adjust the packaging speed to adapt to production needs of different scales. In this way, enterprises can respond to market demand more quickly and shorten delivery time.

2.3 High quality

The automated steel coil packing line not only improves the packaging speed, but also greatly improves the packaging quality of the product. Manual operation is prone to errors, such as loose packaging and material waste. Automated equipment significantly reduces the error rate through precise control and unified standards. The stability and consistency of the steel coil packing machine ensure that each coil of steel can achieve the best packaging effect, thereby reducing damage and waste during transportation.

3. Demand for Steel Coil Packing Machines in Various Countries

With the acceleration of global industrialization, the demand for steel coil packaging machines in many countries has continued to rise. The following is a detailed analysis of the use of steel coil packing lines in some major countries.

3.1 China

As the world's largest steel producer, China has a huge demand for steel coil packing machines. With the country's promotion of modern manufacturing, steel companies have increased their investment in automated equipment. China's steel coil production companies need efficient and fast steel coil packaging machines to meet the needs of domestic and foreign markets, especially in industries such as construction, automobiles and home appliances.

3.2 Germany

Germany is a leader in machinery manufacturing and automation, and its utilization rate of steel coil packing machines is also very high. German steel companies focus on production efficiency and product quality, and automated steel coil packaging machines have become an important means to enhance competitiveness. Many steel producers in Germany have continuously optimized their production processes and reduced production costs by introducing advanced steel coil packing line technology.

3.3 United States

The steel industry in the United States also has a high demand for steel coil packaging machines. With the implementation of environmental protection and energy-saving policies, many companies have begun to pay attention to the efficiency of resource utilization in the production process. The introduction of automated steel coil packing machines not only improves production efficiency, but also reduces energy consumption and material waste. This allows American steel companies to maintain a competitive advantage in the global market.

3.4 Japan

Japan is famous for its precision manufacturing and high-tech automation, and the use of steel steel coil packing lines is also extensive. While pursuing high efficiency and high quality, Japanese steel producers also pay attention to the safety and reliability of equipment. The introduction of automated steel coil packing machines enables companies to achieve rapid production and flexibly respond to market changes while ensuring quality.

3.5 India

India is a rapidly developing emerging market, and the demand for the steel industry is also rising. With the acceleration of infrastructure construction, India's demand for steel coils is increasing. In order to meet market demand, Indian steel companies have begun to introduce modern steel coil packing machines to improve production efficiency and packaging quality.