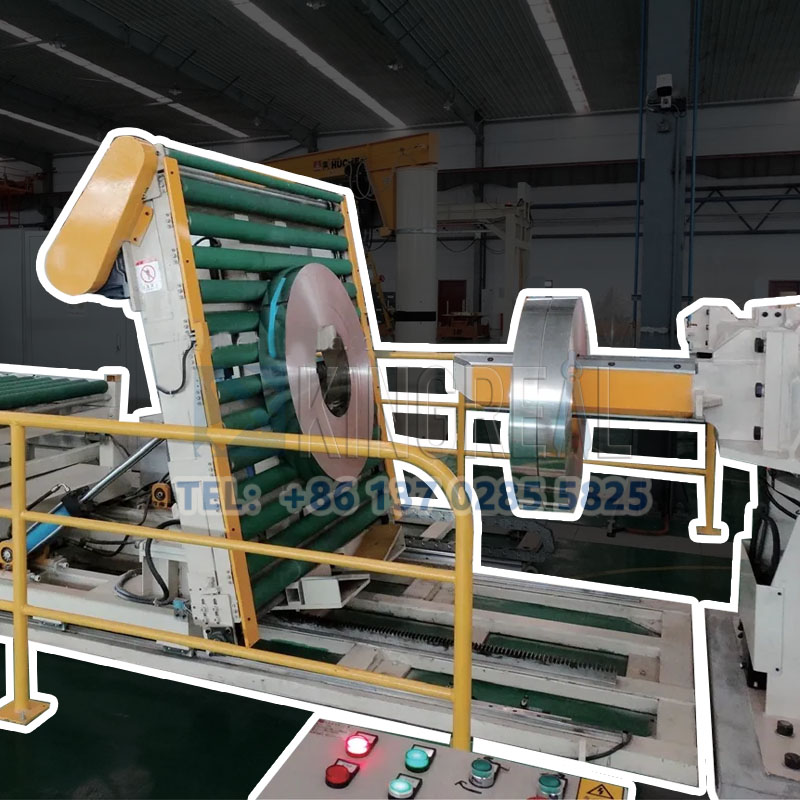

In modern manufacturing, steel coil packing lines are an important complement to steel coil slitting machines. They are usually located downstream of the steel coil slitting machine and are modular production lines responsible for the effective packaging and stacking of cut coils. The main function of the steel coil packaging line is to pick up each individual coil, bundle it radially and stack it to form a neat pile or bundle. Next, these bundled coils will be fixed on the pallet, weighed and labeled to prepare for subsequent transportation and warehousing.

KINGREAL SLITTING steel coil packing machine integrates a variety of equipment, such as steel coil handlers, steel coil trolleys, coil wrapping machines, strapping units and stackers, simplifying the entire process from steel coil slitting production to warehousing. This article will introduce in detail how to use the steel coil packaging line, including its components and specific operating steps, as well as the advantages and parameter settings of the steel coil packaging line.

1. Parameters of Steel Coil Packaging Line

| Diameter | 2200 mm |

| Coil weight | 6000 Kg |

| Stack weight | 12000 Kg |

2. Specific Steps for Using Steel Coil Packing Machine

| Step 1: Preparation | Before using the steel coil packaging line, it is essential to do adequate preparation. The specific steps include: Check the equipment status: Make sure all steel coil packaging line (such as automatic coil hoist, coil wrapping machine, coil strapping machine, etc.) are in good condition. Check the power connection to ensure that the power switch is turned on and the power is supplied normally. Check the control system to ensure that the operation interface is fault-free and can be displayed and operated normally. Clean up the work area: Clean up the area around the steel coil packing machine to ensure that there are no obstacles to avoid accidents during operation. Check whether the ground is dry and non-slip to ensure the safety of the operator. Prepare materials: Prepare wrapping materials (such as HDPE film or paper) and strapping tape according to production needs to ensure sufficient quantity. Check the quality of the materials to ensure that there is no damage or other defects. Train operators: Make sure all operators are trained and understand the operation process and safety precautions of the steel coil packing machine. |

| Step 2: Set parameters | After the preparation work is completed, set the corresponding machine parameters according to the size and weight of the steel coil to be processed. The details are as follows: Adjust the hoist parameters: According to the diameter and weight of the steel coil, adjust the height of the automatic steel coil hoist so that the steel coil can be placed stably during lifting. Set the coil wrapping machine parameters: Select the appropriate wrapping material (HDPE film or paper) and adjust the speed and tension of the coil wrapping machine according to the characteristics of the material. Ensure that the blade of the coil wrapping machine is in good condition for accurate cutting. Configure coil strapping machine settings: Set the strapping method of the coil strapping machine (circular strapping or radial strapping) according to the size and weight of the steel coil, and adjust the tension of the strapping belt. Ensure that the blade and strapping device of the coil strapping machine are working properly to achieve accurate and effective fixation during strapping. Check sensors and alarm systems: Ensure that all sensors (such as position sensors, weight sensors) are working properly and the alarm system is set reasonably so that alarms can be issued in time in abnormal situations. |

| Step 3: Loading the coils | After setting the parameters, load the coils. The specific steps are as follows: Using a forklift or lifting steel coil packing machine: Using a forklift or other lifting equipment, gently place the coils to be processed on the automatic coil hoist. Make sure the coils are placed firmly and not tilted to prevent accidents in subsequent operations. Check the position of the coils: Confirm that the center position of the coils is aligned with the hoist to ensure that they will not shift during the lifting process. Check the surface condition of the coils to ensure that there is no damage or contamination to avoid affecting the subsequent packaging quality. Start the hoist: Start the automatic coil hoist and observe the lifting process of the coils to ensure that they rise smoothly and enter the working area of the steel coil packaging line. |

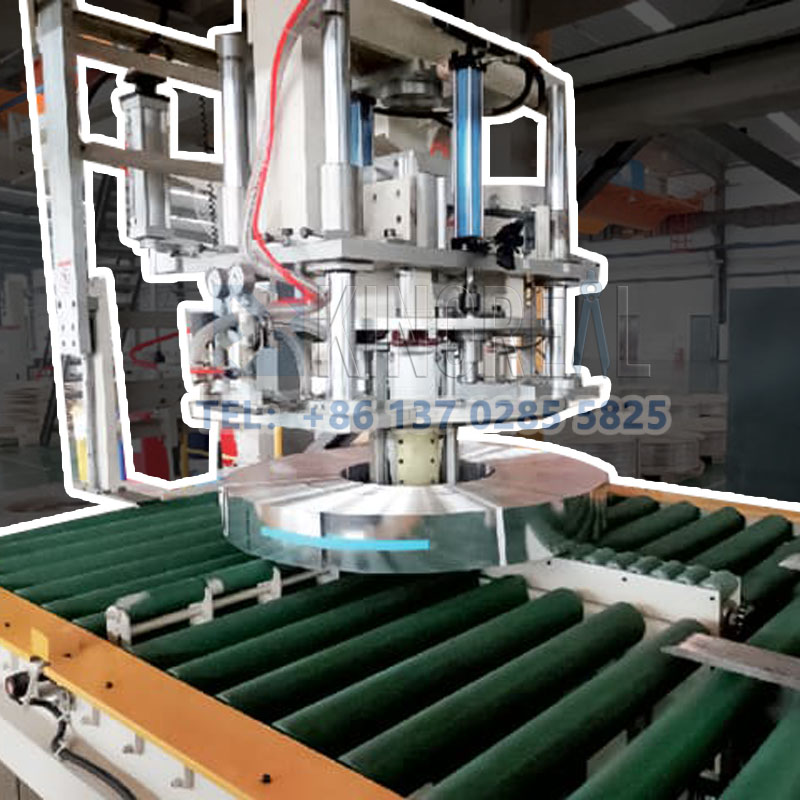

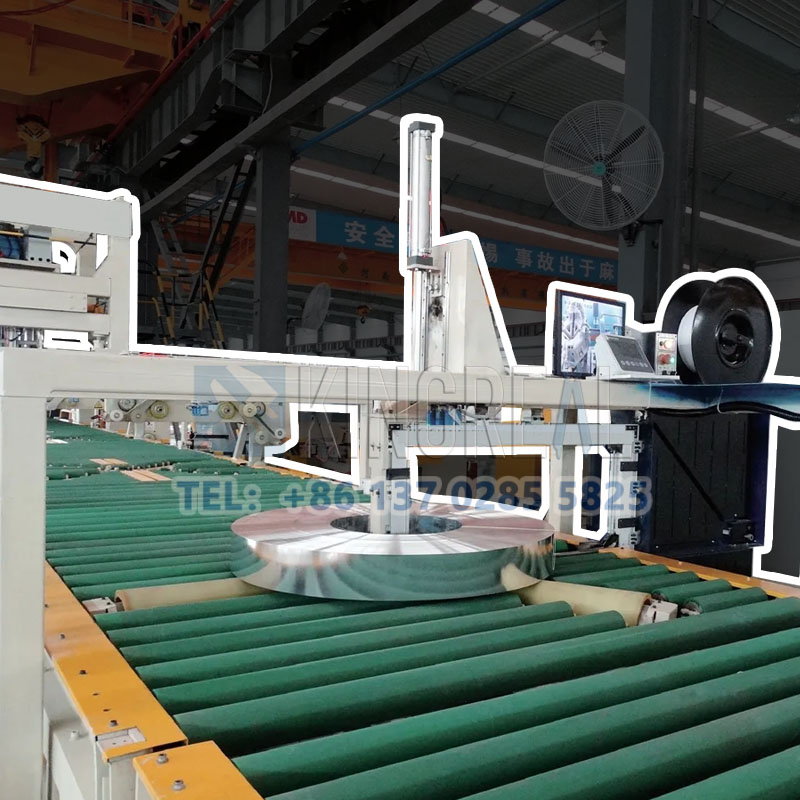

| Step 4: Start the steel coil packing machine | After the coils are successfully loaded, start the steel coil packing machine. The specific process is as follows: Start the control system: Select the "Start" button on the operation panel and the system will run automatically. Monitor the system status to ensure that all steel coil packing machine is operating normally. Automated operation process: The baling line will automatically complete the following operations: Wrapping: The automatic HDPE/paper wrapping machine wraps the steel coil to ensure tight packaging. Adding protective layer: The bubble protection layer and top plate material will be automatically applied to enhance the protective performance. Bundling: The radial strapping machine will bundle the packaged steel coil to ensure its safety during transportation. Stacking: The stacker will stack the bundled coils neatly and prepare for transportation. Real-time monitoring: The operator should monitor the steel coil packing machine status in real time to ensure that the whole process goes smoothly and handle abnormal situations in time. |

| Step 5: Check the finished product | After the packaging is completed, check each bundled coil to ensure that the packaging quality meets the requirements. The specific inspection steps are as follows: Appearance inspection: Check the appearance of the bundled coil to ensure that the packaging is complete and there is no damage or looseness. Confirm whether the label information is complete for subsequent warehousing and transportation. Weighing confirmation: Use an electronic scale to weigh each bundled coil to confirm that its weight meets the production requirements. For coils with abnormal weight, mark and re-check them. Handling of defective products: For defective products found during the inspection, remove or re-pack them, and record relevant information for traceability. |

| Step 6: Transportation and storage | Finally, move the bundled coils to the storage area to ensure their safe storage. The specific steps are as follows: Use the integrated steel coil trolley: Use the integrated steel coil trolley to move the bundled coils to the storage area to ensure that they are firmly placed to avoid rolling or tilting. According to the warehouse layout, arrange the storage location of the coils reasonably to improve storage and retrieval efficiency. Ensure clear identification: Ensure that the label on each bundled coil is clearly visible. The label should include important information such as product information, weight, and production date. Use waterproof labels to prevent moisture damage during storage and transportation. Regularly check the storage status: Regularly check the storage status of the coils in the storage area to ensure that there are no problems such as moisture and corrosion, and maintain a good storage environment. For coils stored for a long time, conduct regular quality inspections to ensure that they still meet the standards before use. |

3. Video of Steel Coil Packing Machine

4. Advantages of Steel Coil Packaging Line

Good packaging is essential to protect products at the metal cut to length line, steel coil slitting line and rewinding outlet. The advantages of steel coil packing machines are reflected in the following aspects:

(1) Protect product quality

By using steel coil packaging lines, it is possible to ensure that the added value generated by the finishing line can be retained during transportation from the coil processing plant to the end user. The steel coil packing machine prevents scratches, rust and other problems that may occur during transportation and storage by effectively bundling and packaging the coils, ensuring that the products are intact.

(2) Improve production efficiency

The automated design of the steel coil packaging line significantly improves production efficiency. By reducing manual intervention and increasing the speed of operation, enterprises can complete a large amount of packaging work in a short time. This efficient production method can quickly respond to market demand and shorten the delivery cycle.

(3) Save labor costs

Automated steel coil packing machines reduce dependence on labor and reduce labor costs. Operators can focus more on monitoring and maintenance of steel coil packaging line instead of heavy manual operations. This not only improves work efficiency, but also reduces the risk caused by human operating errors.

(4) Flexibility to meet different needs

KINGREAL SLITTING steel coil packaging line can be adjusted to different coil sizes, weights and shapes to ensure a perfect fit and minimize waste. This flexibility allows companies to quickly adapt to market changes and meet customers' personalized needs.

(5) Improve storage efficiency

By fixing the bundled coils on the pallet, companies can use storage space more efficiently. The design of the steel coil packing machine takes into account the stability of the stacking, ensuring that a large amount of products can be safely stored in the warehouse, reducing storage costs.