1. Definition of Coil Strapping Machine

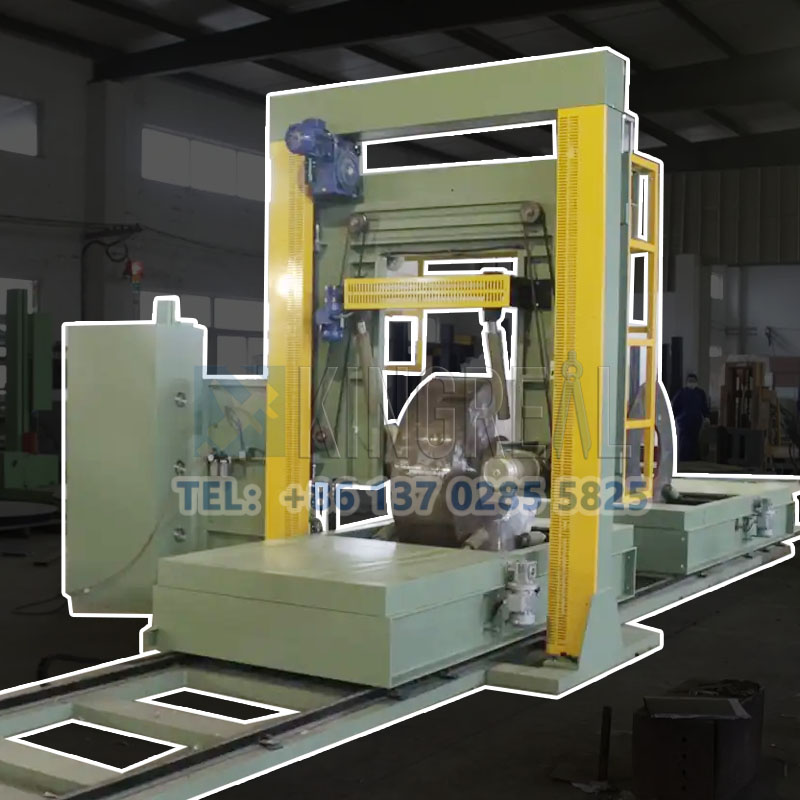

A coil strapping machine is a device specifically used to wrap and fix metal coils. It is usually used in conjunction with a metal slitting machine to efficiently complete the entire process of metal coils from slitting to packaging. Coil wrapping machines are mainly used for core wrapping and packaging of metal coil products of various materials such as large steel coils, aluminum coils, copper coils, stainless steel coils, etc. This metal coil wrapper is designed to improve production efficiency and ensure that the surface of the metal coils is protected from scratches and damage during transportation and storage.

2. Workflow of Coil Wrapping Machine

The workflow of the coil wrapping machine is relatively simple and efficient, and mainly includes the following steps:

(1) Loading

Before the work starts, the metal coils need to be placed in the loading position. At this time, the transport trolley will move the metal coils to the working area of the metal coil wrapper. The loading process is generally completed by an automated system to ensure the accuracy and safety of the operation.

(2) Wrapping

Once the coils are in place, the coil strapping machine will start the winding process. The main components of the equipment will start to wrap the wrapping material (such as plastic strips or steel strips) evenly around the metal coils according to the preset winding program. During the winding process, the coil strapping machine can automatically adjust the winding tightness and speed according to the diameter and width of the metal coil to ensure the quality of winding.

(3) Cutting and fixing

After winding, the equipment automatically cuts the winding material and fixes it on the coil. This step is usually completed by the cutting device and the fixing device to ensure that the winding material will not loosen, thereby maintaining the stability of the coil.

(4) Discharging

Finally, the wound metal coil will be sent out of the work area for subsequent transportation or storage. The discharging process is also assisted by the material transport trolley to facilitate the movement of the wound coil to the designated location.

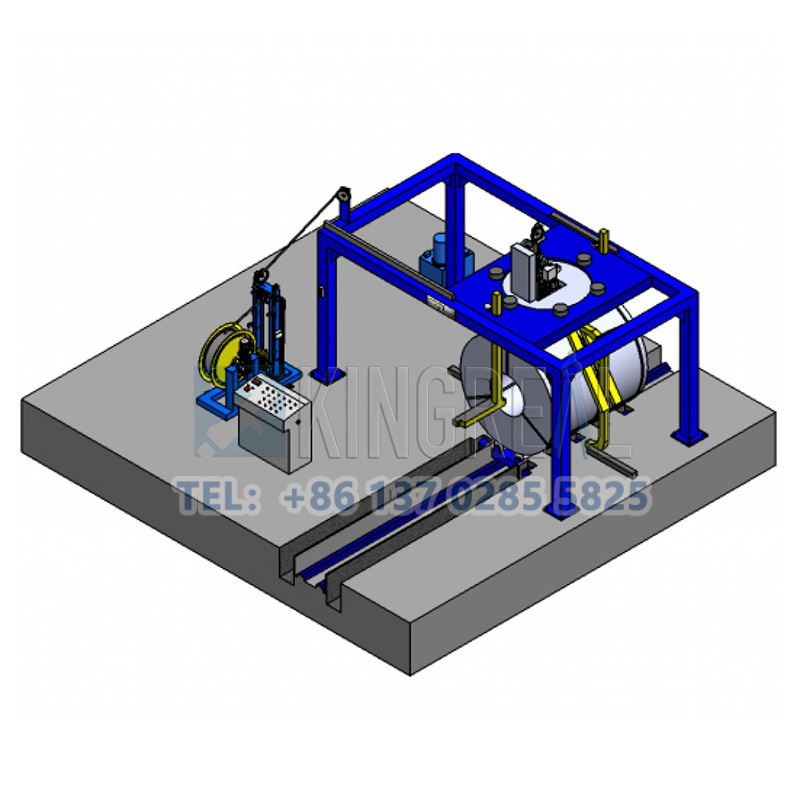

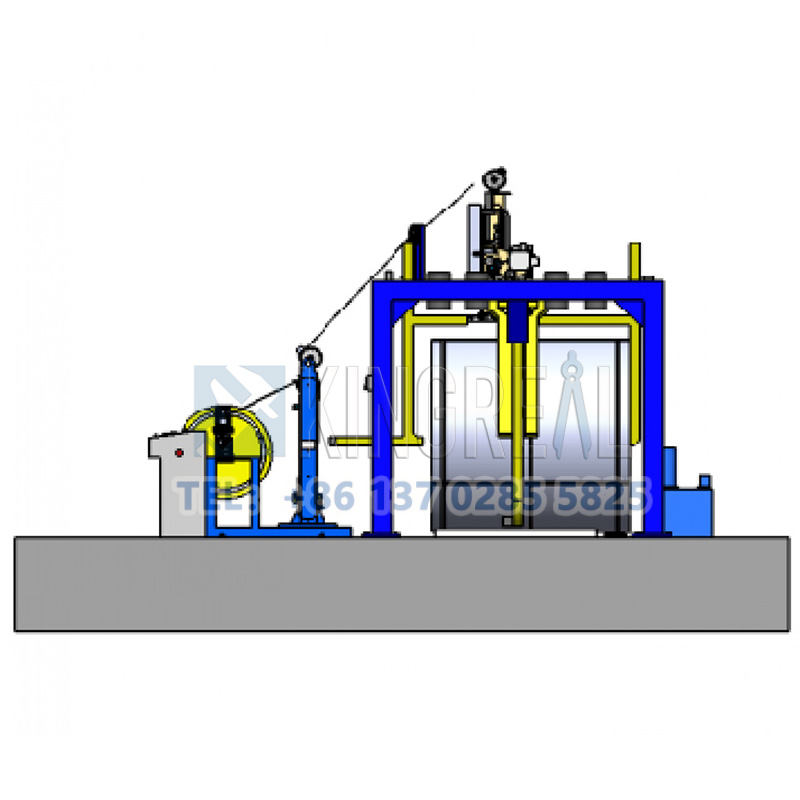

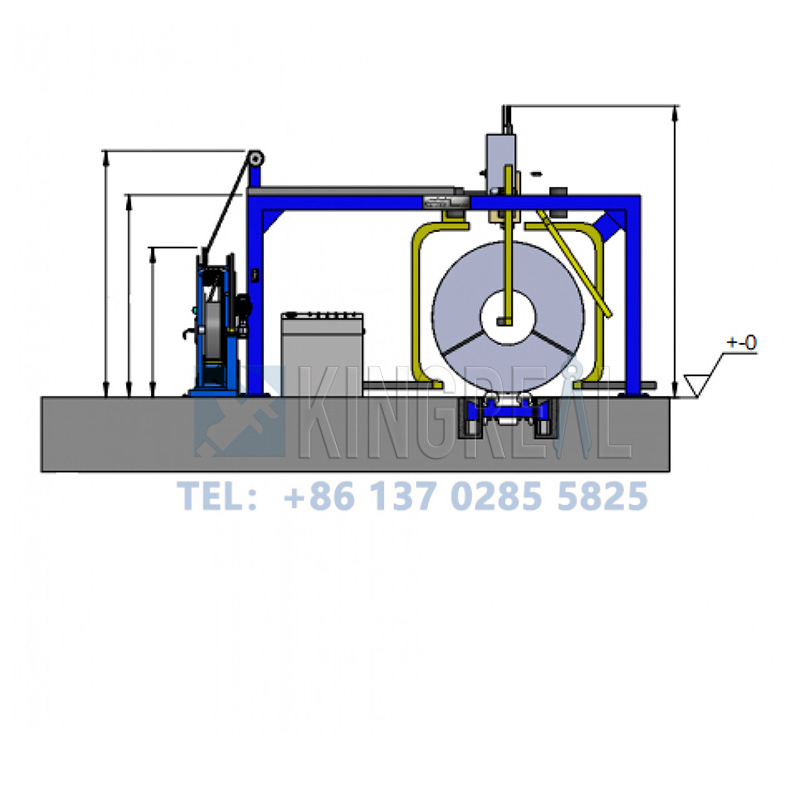

3. Main Components of Metal Coil Wrapper

The structural design of the coil wrapping machine includes several key components, each of which plays an important role in the entire workflow.

(1) Packaging host

The packaging host is the core component of the metal coil wrapper, responsible for performing the main functions of winding, cutting and fixing. Its design allows radial bundling when the metal coil is in a vertical or horizontal position, adapting to different types of metal coils. The efficient operation of the host can greatly increase the production speed.

(2) Carriage

The carriage is used to move the metal coils during the loading and unloading process. Its flexibility and stability ensure the smooth movement of the metal coils in the work process, reducing the need for manual operation and reducing safety hazards.

(3) Control console

The control console is the interactive interface between the operator and the coil wrapping machine, through which winding parameters such as winding speed, tightness, etc. can be set and adjusted. The control console is usually equipped with an intuitive display screen, which allows the operator to monitor the coil strapping machine operation status in real time and make necessary adjustments.

(4) Guardrail

The guardrail is designed mainly to ensure the safety of the operator. It prevents unexpected situations during the winding process and ensures the safety of the operating environment. The guardrail is usually made of strong materials, wear-resistant and easy to clean.

(5) Protective material

During the process of winding the metal coils, the metal coil wrapper will not cause damage to the coils to be bundled. The contact area is protected by HDPE material, which has good wear resistance and flexibility to ensure the safety and effectiveness of the winding process.

4. Uses of Coil Wrapping Machine

The metal coil wrapper has a wide range of uses, mainly reflected in the following aspects:

(1) Wrapping and fixing of metal coils

The main purpose of the coil strapping machine is to wrap and fix metal coils. This wrapping can protect the metal surface during long-distance transportation and avoid scratches and damage. Through wrapping, the metal coil can remain stable during transportation, reducing potential losses caused by friction, collision, etc.

(2) Use with metal slitting machine

The coil wrapping machine can be used with the metal slitting machine of KINGREAL SLITTING to form a complete and efficient slitting process. By combining the coil slitting machine with the coil wrapping machine, the company can realize the automation from the slitting of metal coils to the final packaging, significantly improve production efficiency and reduce manual intervention.

(3) Fully automatic operation

The fully automatic operation mode of the metal coil wrapper reduces dependence on manpower and reduces labor costs. This increase in automation not only improves production efficiency, but also reduces safety hazards during operation. The coil wrapping machine can complete the entire winding process without manual intervention, greatly improving work efficiency.

(4) High winding precision

The high precision of the metal coil wrapper during the winding process ensures the work quality. The uniformity and tightness of the winding material are effectively controlled, which can meet the requirements of different customers for winding quality. This high-precision winding not only improves the appearance quality of the product, but also enhances the transportation safety of metal coils.

5. Increased Demand for Metal Coil Wrapper in Many Countries

Coil strapping machine has been widely used in the metal processing industry in many countries and regions, especially in the following countries:

(1) The United States

The metal processing industry in the United States is also highly developed. Many manufacturers use metal coil wrapper to improve production efficiency and protect metal materials, especially in the automotive and construction industries.

(2) Germany

Germany is famous for its precision manufacturing and high quality standards. Coil wrapping machine has been widely used in the fields of automotive manufacturing, mechanical engineering and metal processing, helping companies to achieve efficient production processes.

(3) Japan

Japan has advanced metal processing technology. Metal coil wrapper is widely used in the processing of steel, aluminum and other metals to ensure the safety of materials during transportation and storage.

(4) India

With the acceleration of industrialization, India's demand for metal processing continues to grow. Metal coil wrapper has gradually become a standard equipment in the steel and aluminum processing industries, helping to improve production efficiency.

(5) Brazil

As the largest economy in South America, Brazil's metal processing industry is developing rapidly, and coil wrapping machine is widely used in the processing of steel and aluminum coils.

(6) South Korea

The manufacturing industry in South Korea is highly developed, especially in the electronics and automotive industries, where metal coil wrapper is used to protect and package metal materials.

The common characteristics of these countries are that they have a strong metal processing industry and growing market demand, which promotes the widespread application of

coil wrapping machine.