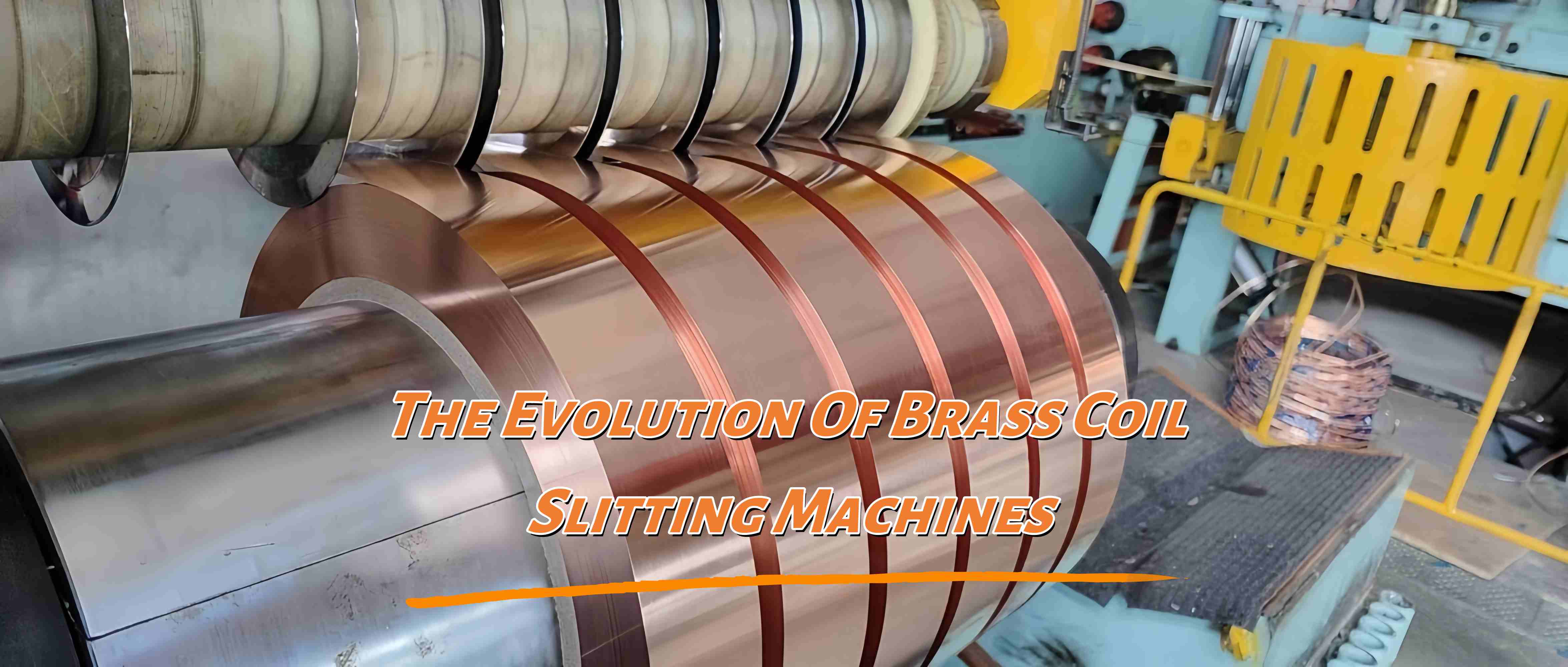

"Brass coil slitting machine is one of the indispensable and important equipment in sheet metal processing. It is specially used to slit large copper coils into narrow strips of the specifications required by customers, and to wind these strips into small coils for subsequent processing. Copper coil slitting machines are widely used in many fields such as transformers, motors, home appliances, automobiles, building materials, and packaging industries, especially when processing materials such as tinplate, galvanized iron, silicon steel sheets, cold-rolled strips, stainless steel strips, aluminum strips, and steel strips. In recent years, with the advancement of technology and the expansion of customer production scale, traditional manual brass coil slitting machines have gradually been replaced by more efficient and more precise fully automatic copper coil slitting machines."

Disadvantages of Manual Brass Coil Slitting Machines

1. Inefficient copper coil slitting machines

The operation of manual brass coil slitting machines requires a lot of manpower and has a slow production speed, which cannot meet the needs of modern large-scale production. This makes many companies appear stretched when facing market competition and it is difficult to increase production.

2. Copper coil slitting machines with insufficient operating accuracy

Due to the limitations of manual operation, the cutting process may result in uneven product quality, uneven cutting, and increased material waste. This not only affects production efficiency, but also increases the cost of the enterprise.

3. Brass coil slitting machines with poor flexibility

Manual copper coil slitting machines usually take a long time to switch production modes or adjust cutting parameters, which makes it difficult for enterprises to respond in time to rapidly changing market demands.

4. Brass coil slitting machines with safety risks

During manual operation, operators face certain safety hazards, especially when handling tools and materials, the risk of accidental injury is high.

Technological Progress of Fully Automatic Copper Coil Slitting Machines

With the development of science and technology, fully automatic brass coil slitting machines have gradually replaced manual copper coil slitting machines and become the mainstream of modern manufacturing. Fully automatic brass coil slitting machines have shown significant technological progress in many aspects.

1. Key components of copper coil slitting machine

(1)Precision tools and slitting systems:

The fully automatic brass coil slitting machine uses gap-less slitting shaft bearings to ensure high-precision slitting quality. High slitting accuracy is achieved through high-precision knife shaft bearings, slitting without burrs, more cutting times, and minimal knife shaft deflection. The introduction of the automatic tool change system reduces the tool replacement time to less than 5 minutes, greatly improving production efficiency. In addition, the double eccentric precision slitting head can automatically adjust the tool gap and is equipped with a fully automatic tool locking system to ensure the stability and safety of cutting.

(2)Efficient feeding and unwinding system:

The automatic strip conveying system and decoiler have greatly reduced the need for manual operation and improved the overall efficiency of the copper coil slitting machine. The introduction of the feeding trolley ensures the automatic handling of metal coils and reduces the labor intensity of operators.

2. Control system

The fully automatic brass coil slitting machine is equipped with an advanced PLC control panel. The operator only needs to enter or adjust the production parameters and click to start the machine, and the copper coil slitting machine will run automatically. The control panel can adjust parameters such as production speed, narrow strip width and quantity in real time, making the production process more flexible and efficient.

Advantages of Fully Automatic Brass Coil Slitting Machine

1. Copper coil slitting machine with high precision

The design and manufacture of the fully automatic brass coil slitting machine fully rely on high-quality blades and advanced PLC control panels, which significantly improves the slitting accuracy of the copper coil slitting machine. By using high-precision knives and advanced slitting technology, the brass coil slitting machine is able to achieve extremely small tolerances when processing copper coils, ensuring that each slit material meets the strict requirements of customers. In addition, each component of KINGREAL SLITTING is manufactured by its own factory, which not only ensures the consistency and reliability of the parts, but also ensures the overall quality and stability of the copper coil slitting machine.

2. Brass coil slitting machine that reduces manpower

The operation of the fully automatic copper coil slitting machine greatly reduces the dependence on manpower, so that the brass coil slitting machine no longer requires a large number of workers to perform heavy manual operations. Traditional manual copper coil slitting machines often require multiple workers to collaborate, while fully automatic brass coil slitting machines reduce labor costs and labor intensity through intelligent control systems and automated mechanical operations. Only a few staff members are required on site to monitor the machine to ensure the safety and stability of the equipment operation. In addition, in order to maximize the liberation of manpower, KINGREAL SLITTING has also equipped the brass coil slitting line with a loading trolley and an unloading trolley, which can realize the automatic handling of coils, thereby further improving production efficiency and the safety of the working environment.

3. Improve production efficiency

KINGREAL SLITTING fully automatic copper coil slitting line can reach a running speed of up to 230m/min, and this excellent performance enables it to meet the needs of large-scale production. In addition, the brass coil slitting line can not only process copper materials efficiently, but also has the ability to process a variety of metal materials such as PPGI and stainless steel, demonstrating its wide adaptability. Customers can flexibly adjust the parameters of the copper coil slitting line according to their own production needs to achieve the best production results.

4. Meet personalized production needs

The manufacturing plan of the automatic brass coil slitting line is mainly customized according to the actual needs of customers, providing customers with personalized solutions. For example, if customers need to produce higher precision finished products to avoid surface scratches, KINGREAL SLITTING can provide belt tension coil slitting machines to ensure that the product surface is smooth and flawless throughout the production process. Similarly, if customers need to process metal coils with a thickness of more than 6mm, KINGREAL SLITTING can also provide heavy duty slitting machines to meet the needs of different thicknesses and material properties. Through this personalized design and manufacturing capability, KINGREAL SLITTING ensures that customers can achieve the best production results under different production conditions.