"The coil slitting line is a special equipment for metal sheet processing. It is mainly used to cut wide metal coils into several narrow coils by shearing. It is widely used in the automotive, electric power, home appliances, construction and other industries. In the process of processing transformer cores, the coil slitting line is needed to slit silicon steel coils. Explore the advantages and characteristics of silicon steel slitting lines to help customers in the metal coil processing industry learn more professional details."

What Is Benefit Of Silicon Coil Slitting Line?

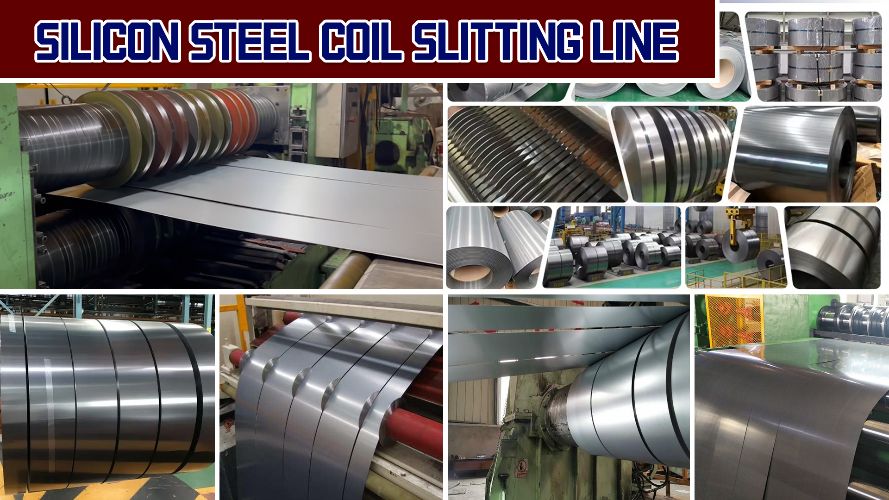

Silicon steel slitting line, transformer core silicon steel sheet high-precision slitting production line passes through a buffer device or a buffer pit and then is cut by a rolling shear device to form multiple strips of material, and multiple strips of material are arranged in sequence perpendicular to the transmission direction. Several strips of silicon steel material are guided in the transmission direction of the slitting line, and the cutting edges of each strip are polished to remove the burrs on the edges. The polished strips are reeled through a reel, which can improve the overall stability and manufacturing accuracy of the silicon steel sheet slitting system.

1. Silicon Coil Slitting Line Cutter Shaft Design

Silicon coil slitting line uses high-precision machine tool spindle bearing support, which makes the axial and radial runout of the cutter shaft small; at the same time, its cutter disc adopts a three-point positioning and locking method of nuts (, not only for accurate dimensional accuracy but also for the function of firm locking. In order to more conveniently adjust the longitudinal shearing speed, electronic control components and hydraulic components are used, which not only have high working reliability and strong anti-interference ability of the control system, but more importantly, it has a self-diagnosis function, which can help quickly query the cause of the fault. In addition, it can be clearly seen that the longitudinal shear of the longitudinal shearing machine is positioned and installed using an eccentric sleeve. Even if the shearing weight of the eccentric distance is changed, its material feeding height will not change, which is both reliable and safe.

2.Belt Tension Bridge For Silicon coil slitting line

During the operation of Silicon coil slitting line, tension is one of the most important skill indicators. This parameter is involved when Silicon coil slitting line is reeled and unreeled. In order to better control the tension in Silicon coil slitting line, tension controller has become one of the indispensable parts of Silicon coil slitting machine. The tension controller calculates the coil diameter and load torque by detecting the linear speed of reeling, thereby setting the tension. Since the tension control of Silicon coil slitting machine can output a standard analog signal of zero to ten volts, corresponding to the rated torque of the asynchronous motor, the analog signal can be connected to the frequency converter to select the torque setting. In this way, the tension can be kept constant during the operation of the equipment.

If it is in tension control mode, whether it is a DC motor, AC motor or servo motor, the speed must be limited, otherwise when the torque generated by the motor overcomes the load torque and runs, it will generate rotation acceleration, and the speed will continue to increase until the highest speed.

FAQ About Silicon Coil Slitting Line:

1. What are the characteristics of silicon steel?

●Excellent magnetic properties

Silicon steel has good magnetic permeability and low hysteresis loss, making it an important material in the manufacture of electromagnetic equipment. The higher the magnetic permeability of silicon steel, the lower the hysteresis loss, which improves the power factor and thus improves the efficiency of the equipment.

●Efficient conduction performance

Silicon steel has very high conductivity and electrical conductivity, and can produce very small energy loss when current flows. This excellent conduction performance makes silicon steel widely used in dry power converters, power transmission systems and electronic equipment.

●Excellent processing performance

Silicon steel has good processability and formability, which can meet the high requirements of material shape and size in different industrial fields. At the same time, silicon steel has a smooth surface and excellent surface quality, which can meet the requirements of precision manufacturing.

2. What is the difference between oriented silicon steel and non-oriented silicon steel?

Oriented silicon steel is a cutting-edge functional material necessary for power transmission. It is also a key material for manufacturing ultra-high voltage, ultra-high voltage and high-efficiency transformers. It can effectively reduce the power loss in the power transmission and distribution process. So do you know the difference between oriented silicon steel and non-oriented silicon steel?

●Different properties

(1) Oriented silicon steel: Oriented silicon steel, also known as cold-rolled transformer steel, is an important ferrosilicon alloy used in the transformer (iron core) manufacturing industry.

(2) Non-oriented silicon steel: Non-oriented silicon steel is a ferrosilicon alloy with a very low carbon content. Its grains are randomly oriented in the steel plate after deformation and annealing.

●Different characteristics

(1) Oriented silicon steel: Oriented silicon steel has strong directional magnetism, with the lowest iron loss in the rolling direction, the highest magnetic permeability and a high magnetic induction value under a certain magnetizing field. The silicon content of oriented silicon steel is about 3%, and the steel is required to have a low oxide inclusion content and contain certain inhibitors (MnS, A1N).

(2) Non-oriented silicon steel: Non-oriented silicon steel is a silicon-iron alloy containing 0.8%-4.8% silicon, which is hot-rolled and cold-rolled into silicon steel sheets with a thickness of less than 1mm. Adding silicon can increase the resistivity and maximum magnetic permeability of iron, and reduce coercivity, core loss (iron loss) and magnetic aging.

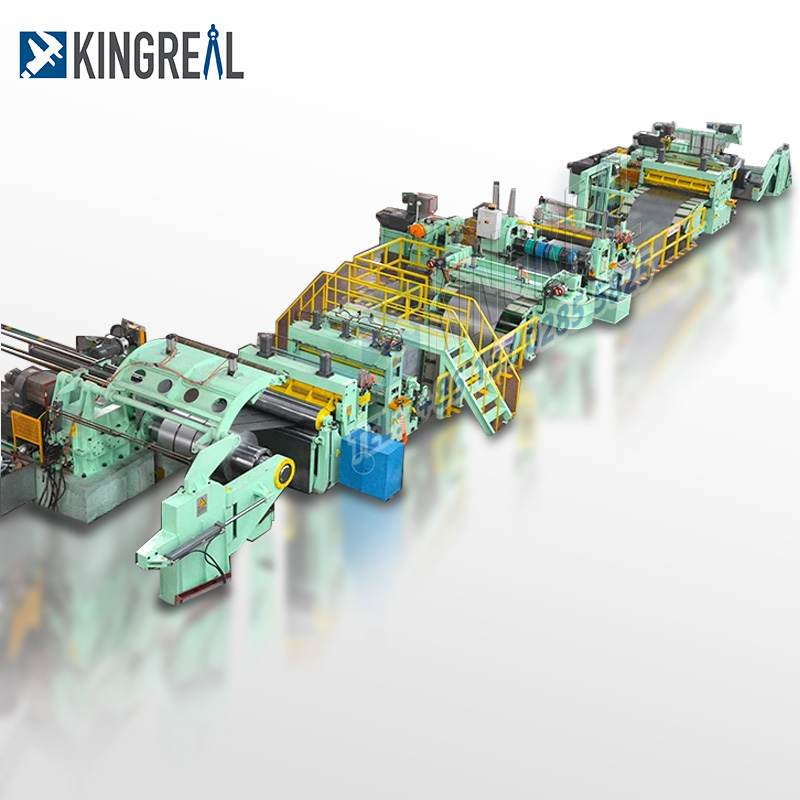

KINGREAL SLITTING is a professional coil processing equipment manufacturer in China. We customize the design of core components such as slitting line blades according to the characteristics of metal raw materials. Silicon steel slitting line is one of KINGREAL SLITTING most distinctive products. We can provide CRGO silicon slitting machine and GOES silicon steel slitting machine.