"Medium gauge cut to length lines are playing an increasingly important role in the modern metalworking industry. The emergence of medium duty cut to length lines, in particular, fills the gap between light gauge cut to length lines (0.2-3mm) and heavy gauge cut to length lines (6-20mm). KINGREAL SLITTING offers customized designs tailored to the thickness of the materials being processed. KINGREAL SLITTING medium gauge cut to length lines are specifically designed for processing coils with thicknesses ranging from 0.3mm to 6mm. Due to their wide range of applications, medium duty cut to length lines have found widespread application in the metalworking industry."

▎Introduction to Medium Duty Cut to Length Line

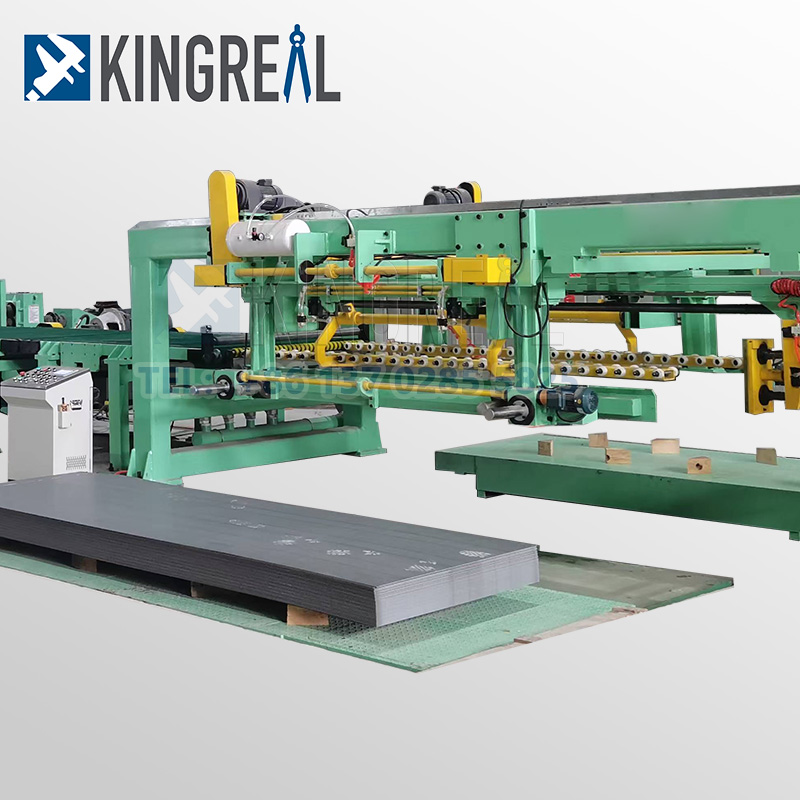

Medium gauge cut to length lines uncoil, level, and shear cold-rolled, hot-rolled, and stainless steel coils into various sizes of cut-to-length sheets. The standard configuration includes a loading trolley, decoiler, feeder, limiter I, leveling machine, storage bin, limiter II, shearing machine, conveyor table, pneumatic discharge rack, hydraulic lift, unloading table, hydraulic system, and electrical control system. The main components of the hydraulic system of this medium duty cut to length line utilize high-precision components from renowned brands, and the cut-to-length system is controlled by a fully positioned servo system. The electrical control system utilizes an imported PLC program controller.

▎Fully Automatic Medium Duty Cut to Length Line Manufacturing Solution

Compared to traditional cut to length lines, KINGREAL SLITTING newly launched fully automatic medium duty cut to length line better meets the high-tech requirements of modern society. Automation is a key feature of this medium gauge cut to length line, primarily reflected in the following aspects:

1. Fully automatic operation for medium duty cut to length line

The fully automatic medium gauge cut to length line minimizes manual labor. Users just specify cutting length and speed on the control panel, then the medium duty cut to length line automatically adjusts based on those specifications. This invention improves manufacturing efficiency and lowers the demand for human involvement greatly. With a small staff, this fully automated design lets the plant preserve a high production level.

2. Precision cutting for medium gauge cut to length line

High-precision servo systems on the medium duty cut to length line guarantee accurate cutting following the user's predetermined cutting length. To ensure the quality of the final product, length tolerance is managed within ±1.0mm. This cutting power makes the medium gauge cut to length line especially suited for demanding sectors like as automotive and aerospace where it meets the strict requirements for material quality and strength.

3. Automatic stacking for medium duty cut to length line

The medium gauge cut to length line is also equipped with an automatic stacker that quickly stacks cut plates. Plates are automatically fed to the stacking table by a robotic arm or pneumatic device, reducing the need for manual handling. This feature not only reduces labor costs but also improves work quality and speed. Automated stacking enables employees to concentrate on other vital tasks, hence raising overall production efficiency, as well as lowering labor expenses.

4. Raw material compatibility for medium duty cut to length line

Stainless steel, copper, aluminum, hot-rolled, and cold-rolled among other metal kinds can all be processed using the medium gauge cut to length line. Rather than being restricted to one substance, this varied raw material compatibility enables one medium duty cut to length line to process various kinds of coils. This feature not only increases medium gauge cut to length line utilization but also provides customers with greater flexibility to meet diverse production needs.

5. Modular equipment design for medium duty cut to length line

KINGREAL SLITTING medium gauge cut to length lines feature a modular design, allowing customers to flexibly configure various components of the equipment to suit their production needs. For example, customers can choose from decoiler, leveling machine, and cutting system of varying specifications to accommodate different material types and thicknesses. This flexibility not only meets individual customer needs but also reduces unnecessary investment.

6. Efficient hydraulic and electrical systems for medium duty cut to length line

The hydraulic system of the medium gauge cut to length line utilizes high-precision components to ensure stability and reliability. Through optimized design, the hydraulic system maintains efficient operation under varying operating conditions, reducing energy consumption. The electrical control system utilizes the latest PLC technology, ensuring intelligent and automated equipment, real-time monitoring of the production process, and timely feedback on production status, ensuring safe and efficient production.

▎Advantages of Medium Duty Cut to Length Line

1) Improved production efficiency

Through automation and efficient design, the medium gauge cut to length line significantly improves production efficiency. Automated operations reduce reliance on manual labor, lowering labor costs. Precise cutting and automatic stacking shorten production cycles, enabling customers to more quickly respond to market demands.

2) Lower production costs

The medium gauge cut to length line's efficient operation and multi-material adaptability directly reduce production costs. Customers can use the same medium duty cut to length line to process multiple materials, reducing equipment investment and maintenance costs. Furthermore, reduced manual labor and increased production speeds effectively lower overall production costs.

3) Improve product quality

The medium gauge cut to length line's precise cutting and efficient leveling ensure high-quality end products. Whether in terms of dimensional accuracy or material flatness, the medium duty cut to length line meets customers' demand for high-quality products.

If you need more information about medium gauge cut to length lines, please contact KINGREAL SLITTING! KINGREAL SLITTING professional technical team can provide detailed equipment specifications, performance data, and application examples. Whether you're interested in specific configurations, production capacity, or suitable materials for medium duty cut to length lines, KINGREAL SLITTING can provide accurate and timely answers.

KINGREAL SLITTING is committed to providing customers with personalized medium gauge cut to length line solutions to meet your specific metalworking needs. KINGREAL SLITTING sales and technical support teams are ready to provide consulting services and help you select the most suitable medium duty cut to length line. Whether it's a first-time purchase or a subsequent equipment upgrade, KINGREAL SLITTING will provide professional advice and support.

If you want to stay updated on KINGREAL SLITTING latest medium gauge cut to length line projects, stay tuned to KINGREAL SLITTING! KINGREAL SLITTING regularly publishes industry news, technical updates, and success stories to help you stay informed about market trends and technological developments. Through KINGREAL SLITTING official website, social media and newsletters, you will be the first to get information about new medium gauge cut to length line releases, technological innovations and customer feedback.