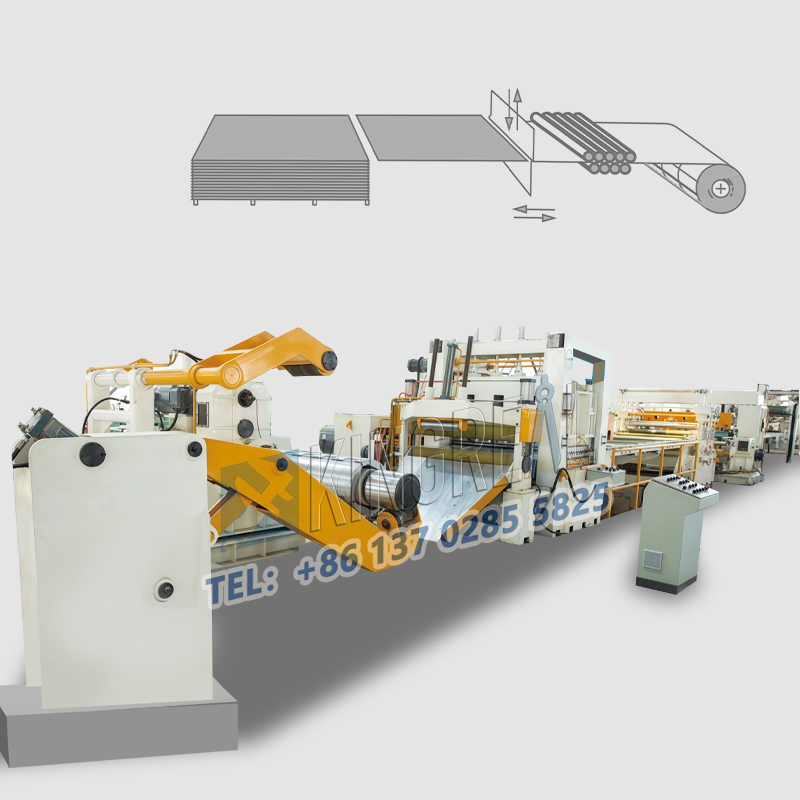

"KINGREAL SLITTING, a professional manufacturer of compact cut to length lines, is committed to providing customers with efficient and reliable metal coil processing solutions. KINGREAL SLITTING compact cut to length machines are primarily used to decoil, level, and cut metal coils to length, converting them into flat sheets for stacking. Suitable for a variety of materials, including cold-rolled and hot-rolled carbon steel, silicon steel, and stainless steel, KINGREAL SLITTING compact cut to length machine not only offers high precision and efficiency, but also customizable parameters and automated production features to meet diverse customer needs. This article will detail KINGREAL SLITTING compact cut to length line advantages, customized solutions, and why you should choose KINGREAL SLITTING as your compact cut to length machine manufacturer."

Why Choose KINGREAL SLITTING Compact Cut To Length Line?

1. Extensive compact cut to length line project

KINGREAL SLITTING has extensive compact cut to length machine project experience, having provided customized compact cut to length line solutions for customers in countries including the United States, Russia, India, and Bangladesh. KINGREAL SLITTING engineers have a deep understanding of market needs and regulatory differences in each region, ensuring that each solution is adapted to local climate conditions and industry standards. Through these projects, KINGREAL SLITTING has accumulated valuable experience and continuously optimized its compact cut to length machine design and production processes.

2. One-stop service and support for compact cut to length line

KINGREAL SLITTING provides comprehensive one-stop service, including pre-sales consultation and after-sales support. During the pre-sales phase, KINGREAL SLITTING will accompany customers on a factory tour to understand their specific needs and propose customized solutions. For after-sales service, KINGREAL SLITTING provides on-site compact cut to length machine installation and commissioning, as well as regular maintenance to ensure long-term, stable operation. KINGREAL SLITTING also offers technical training to help customers better master compact cut to length machine operation and maintenance.

3. Highly customizable parameters of compact cut to length line

KINGREAL SLITTING compact cut to length machines feature highly customizable parameters that can be adjusted to meet specific customer needs. For example:

Decoiler for compact cut to length line: Can handle metal coils from 5 to 30 tons, meeting production needs of varying sizes.

Maximum Width and Thickness: Customizable width up to 100 mm, with thickness up to 2 or 3 mm depending on the model.

Adjustable Number of Cutting Heads for compact cut to length line: 2 to 16 cutting heads are available to accommodate diverse cutting requirements. This flexibility allows KINGREAL SLITTING compact cut to length machines to adapt to various production environments, ensuring optimal production efficiency.

Features of Compact Cut to Length Machine

1. Compact design for compact cut to length line

Designed to save space, the compact cut to length machine is ideal for small-scale production environments. Many companies, despite limited space, still seek to improve production efficiency. KINGREAL SLITTING compact cut to length machine utilizes every inch of space through precise layout and design while ensuring ease of operation.

2. High automated compact cut to length line

KINGREAL SLITTING compact cut to length lines feature a high degree of automation, enabling fast cutting and high-precision production. This automation not only improves production efficiency but also reduces manual intervention, thereby reducing the risk of human error.

3. Simple operation for compact cut to length machine

KINGREAL SLITTING prioritizes user experience, and the user interface of the compact cut to length line is simple and intuitive, making it easy for operators to quickly learn how to use it. Furthermore, maintenance and servicing are also very convenient, reducing downtime and improving overall production efficiency.

Customized Solutions for Compact Cut to Length Machine

The material handling and straightening components of KINGREAL SLITTING compact cut to length lines are fully customized to the customer's material needs. KINGREAL SLITTING supports split or two-in-one equipment combinations (such as GO, ML, CL, and TGL), allowing us to tailor the most suitable solution for our customers.

1. Material loading section for compact cut to length line

The material loading section is selected based on the customer's material width and inner and outer diameters. For different material thicknesses, we will configure the compact cut to length machine based on the pressing method, load requirements, and power level. Furthermore, for the international market, safety is a key consideration, so we recommend including a pressing arm and variable frequency drive as standard features in your quote.

2. Straightening section for compact cut to length line

The straightening section design determines the size and arrangement of the straightening wheels based on the material thickness. KINGREAL SLITTING will determine the number and arrangement of straightening wheels based on the customer's flatness requirements to ensure final product quality.

3. Feeding section for compact cut to length machine

The feeding section is differentiated based on the customer's sheet material length requirements and efficiency. KINGREAL SLITTING offers various power source options, including AC variable frequency drive, DC motor drive, and servo motor drive, to meet diverse customer needs.

4. Shearing system for compact cut to length line

Customers can choose between the compact cut to length line's built-in shears, external hydraulic shears, or pneumatic high-speed shears for shearing. KINGREAL SLITTING will provide the appropriate shearing equipment to meet diverse production needs and ensure production efficiency. Common shearing methods include fly shearing, swing shears, and fixed shears, all of which KINGREAL SLITTING offers.

5. Product collection for compact cut to length line

The product collection method is selected based on the customer's production needs. KINGREAL SLITTING offers manual collection, simple lifting collection, and automatic palletizing collection to accommodate varying production scales and efficiency requirements.

In addition to compact cut to length lines, KINGREAL SLITTING also offers a variety of specialized metal cut to length machine solutions, including light gauge cut to length lines, heavy gauge cut to length lines, fly shearing gauge cut to length lines, fixed shearing cut to length line, swing shearing cut to length lines, rotary shearing cut to length lines, and high speed cut to length lines. If you have any questions or needs regarding compact cut to length machines, please feel free to contact KINGREAL SLITTING! We are your trusted and preferred compact cut to length line manufacturer!