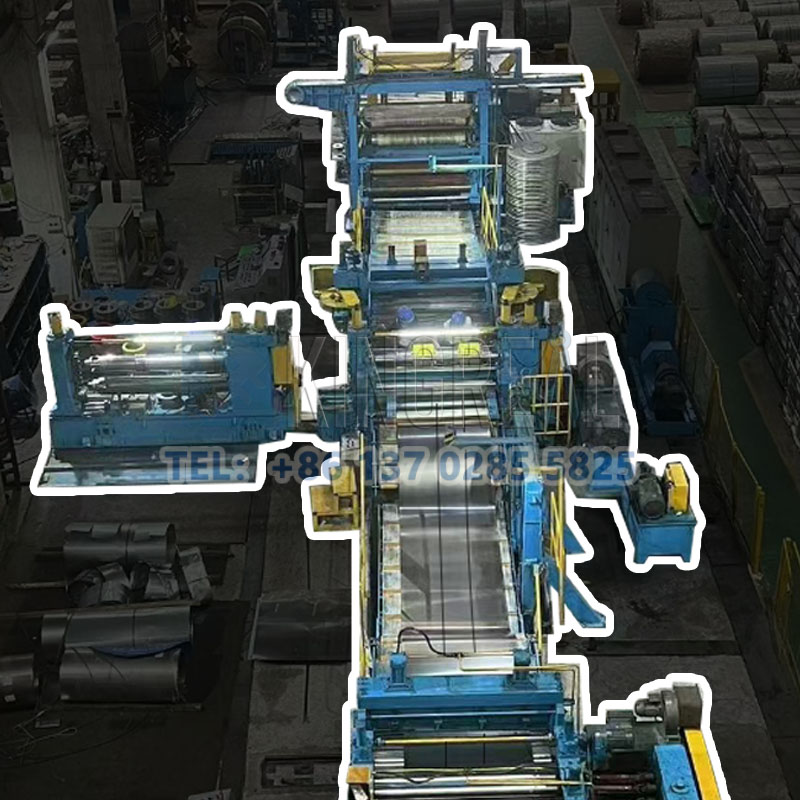

In modern manufacturing, aluminum slitter, as a key equipment, is widely used in the processing and production of aluminum. As a professional coil slitter manufacturer, KINGREAL SLITTING has more than 20 years of rich experience, integrating design, R&D, manufacturing and sales. KINGREAL SLITTING metal slitting machines not only cover aluminum slitter, but also include slitting solutions for various materials such as silicon slitting machine, hot rolled coil slitter, cold rolled coil slitter and PPGI coil slitting machine.

In this article, KINGREAL SLITTING will focus on aluminum coil slitting machine and show how KINGREAL SLITTING can provide customers with different aluminum slitter solutions to meet various production needs.

Reasons Why Market Needs Aluminum Coil Slitting Machine

Aluminum is widely used in many industries such as construction, transportation and packaging due to its light weight, corrosion resistance and excellent formability. As the importance of sustainability becomes increasingly prominent, the application areas of aluminum continue to expand. For example, construction companies are increasingly using aluminum for exterior building materials to improve the durability and aesthetics of buildings. Automakers use the advantages of aluminum in lightweighting vehicles to improve fuel economy and reduce emissions.

In addition, as the market demand for high-quality aluminum materials increases, the demand for aluminum coil slitting machines is also rising. Aluminum slitter can not only improve production efficiency, but also ensure product quality and consistency. Therefore, choosing the right aluminum coil slitting machine is crucial to the manufacturer's production capacity.

KINGREAL SLITTING Provides Different Aluminum Slitter solutions

●In-depth understanding of customer needs

When designing an aluminum coil slitting machine, it is crucial to understand the specific needs of customers. Each customer's production environment, material specifications, and market demand may be different. Therefore, when providing customers with aluminum coil slitting machine solutions, KINGREAL SLITTING will conduct a detailed demand analysis, including the following aspects:

1. Material model

There are many types of aluminum materials, and the common ones include different alloys such as AA1050, AA3003, and AA5052. Each alloy is different in strength, ductility, and corrosion resistance, so in the design of the aluminum slitter, the characteristics of the selected aluminum alloy must be fully considered.

Aluminum alloy characteristics: Different aluminum alloys may exhibit different cutting and forming properties during processing. For example, AA1050 is suitable for low-strength applications, while AA5052 is used in environments that require higher strength and corrosion resistance. KINGREAL SLITTING aluminum coil slitting machine can be optimized according to the material characteristics to ensure the best cutting effect.

2. Material thickness

The design of the aluminum coil slitting machine also needs to be adjusted according to the thickness of the aluminum used by the customer. KINGREAL SLITTING aluminum slitter can usually handle a thickness range of 0.1 mm to 4.0 mm. When choosing an aluminum coil slitting machine, customers should clarify the thickness of the aluminum to be processed so that KINGREAL SLITTING can provide the most suitable aluminum slitter configuration.

Thickness adjustment: For thicker aluminum, the knives and rollers of the aluminum slitter need to have higher strength and stability to ensure accuracy and efficiency during the cutting process. KINGREAL SLITTING will provide the corresponding blade configuration and roller materials according to customer needs to ensure that it can still maintain efficiency and precision when processing aluminum of different thicknesses.

3. Number of slitting strips

The design of the slitting machine also needs to consider the number of strips that the customer wants to cut from the aluminum coil. The number and configuration of the blades of the aluminum coil slitting machine directly affect the production efficiency and cost of the product.

Multi-blade configuration: If customers need to slit multiple strips from a coil of aluminum, KINGREAL SLITTING aluminum coil slitting machine can be configured with multiple blades according to customer requirements to achieve simultaneous slitting. This configuration can greatly improve production efficiency, shorten production cycle, and reduce the production cost per unit product.

Minimum strip width: In addition, the minimum strip width that KINGREAL SLITTING aluminum coil slitting machine can achieve is usually 10 mm or less. Customers can choose the appropriate bandwidth according to market demand to meet the needs of different application scenarios.

4. Tolerance requirements

In the aluminum slitting process, it is very important to maintain the consistency of strip width. When designing aluminum slitter, KINGREAL SLITTING can usually ensure a tolerance range of ±0.1 mm to ±0.5 mm. This precision requirement is an important consideration for many customers when choosing aluminum coil slitting machines.

Tolerance control: Through high-precision knives and advanced control systems, KINGREAL SLITTING ensures a consistent cutting width throughout the entire coil length. KINGREAL SLITTING team will professionally adjust the aluminum slitter according to the customer's specific tolerance requirements to ensure that the aluminum strip that meets the standards is produced.

5. Speed and capacity

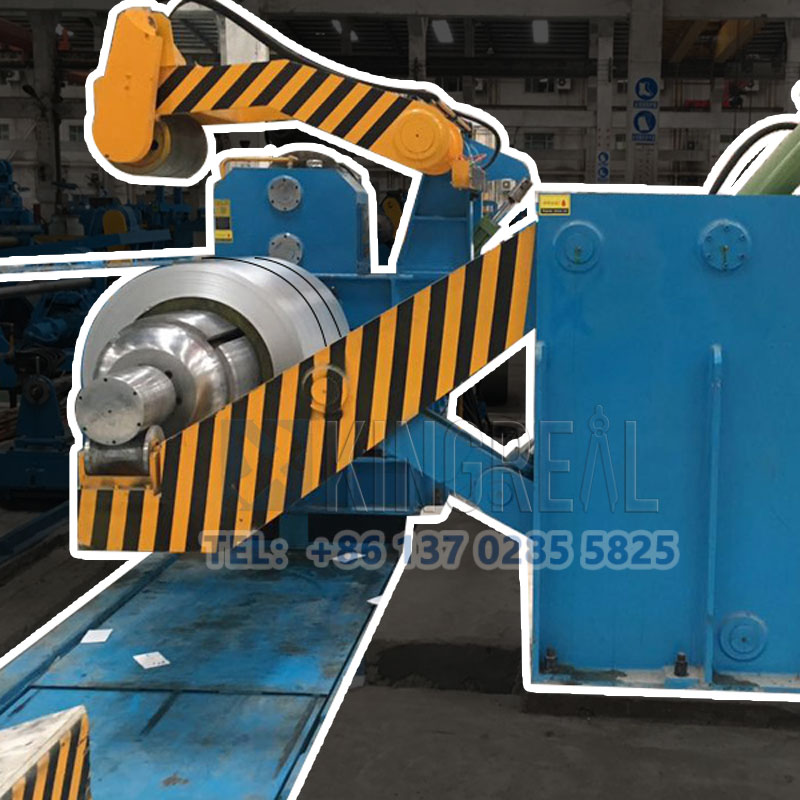

The speed and capacity of the aluminum slitter are important factors for customers when choosing an aluminum coil slitting machine. KINGREAL SLITTING aluminum coil slitting machine can provide different line speeds according to customer needs.

Strong adaptability: For customers who need large-scale production, KINGREAL SLITTING aluminum coil slitting machine can run at a higher speed, improve production efficiency, and meet the needs of large-volume orders. For small-volume production, the aluminum slitter can also adjust the speed according to the specific situation to achieve higher flexibility and adaptability.

Maximum coil weight and outer diameter: KINGREAL SLITTING aluminum slitter can usually handle a maximum coil weight of up to 20 tons and a maximum coil outer diameter of up to 2000 mm, ensuring stable operation of the aluminum slitter under high load conditions. This design enables KINGREAL SLITTING aluminum coil slitting machine to meet the production needs of different customers, whether it is a small factory or a large manufacturing company.

●KINGREAL SLITTING Customization Process

In order to ensure that it can provide the aluminum coil slitting machine solution that best suits customer needs, KINGREAL SLITTING has established a complete customer customization process. This process includes the following steps:

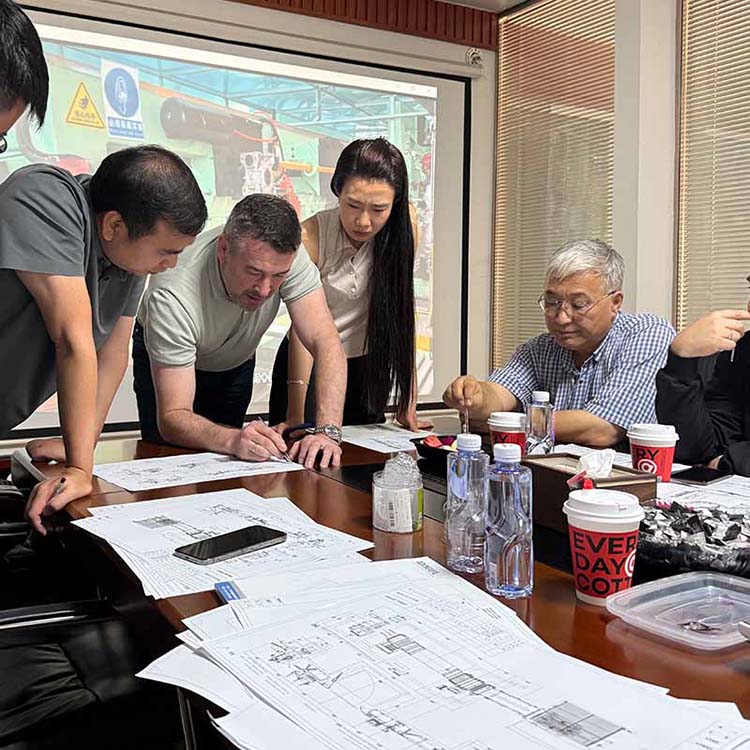

1. Initial consultation

Customers can contact KINGREAL SLITTING by phone, email or online consultation. KINGREAL SLITTING sales team will have initial communication with customers to understand their basic needs, including material type, thickness, number of slitting strips, etc.

2. Demand Assessment

After the initial consultation, KINGREAL SLITTING engineering team will evaluate the information provided by the customer. According to the customer's production environment and market demand, KINGREAL SLITTING will develop a preliminary aluminum coil slitting machine configuration plan.

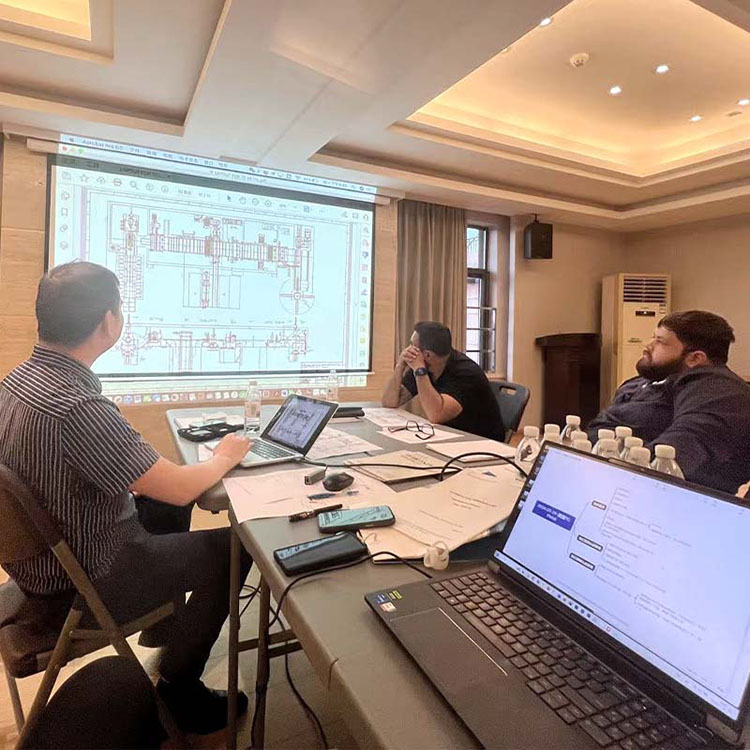

3. Scheme Design

Based on the demand assessment, KINGREAL SLITTING will provide customers with a detailed aluminum coil slitting machine design plan, including technical parameters, equipment configuration and production capacity. Customers can discuss and provide feedback based on the plan, and KINGREAL SLITTING will make adjustments based on customer opinions.

4. Customized Production

Once the plan is determined, KINGREAL SLITTING will enter the production stage. KINGREAL SLITTING production team will precisely manufacture the aluminum coil slitting machine according to the design plan to ensure that every detail meets the customer's requirements.

5. Installation and commissioning

After the production is completed, KINGREAL SLITTING technical team will be responsible for the installation and commissioning of the aluminum slitter to ensure that the aluminum slitting machine can run smoothly at the customer's site. KINGREAL SLITTING will conduct comprehensive tests to verify the performance and stability of the aluminum coil slitting machine.

6. Training and after-sales service

To ensure that customers can operate the aluminum coil slitting machine proficiently, KINGREAL SLITTING provides professional operation training. At the same time, KINGREAL SLITTING will also provide comprehensive after-sales service to ensure that the problems encountered by customers during use can be solved in a timely manner.