Customized Metal Coil Slitter Solutions

KINGREAL SLITTING offers a comprehensive range of steel coil slitting machines tailored to meet the diverse production needs of customers across various industries.Understanding that different production processes require specific equipment, KINGREAL SLITTING has developed an extensive portfolio of machines designed to handle various types of raw materials and production volumes.For instance, based on the thickness of raw materials that customers need to process, KINGREAL SLITTING has introduced a variety of slitting machines, includinglight gauge metal coil slitters, medium gauge metal coil slitters, and heavy gauge metal coil slitters, each equipped with advanced technology to ensure precise and efficient cutting.

Moreover, considering the differences in material properties, KINGREAL SLITTING provides specialized machines for different types of steel coils, such as hot-rolled steel coil slitting machines and cold-rolled steel coil slitting machines, to optimize the cutting process for each type of material.

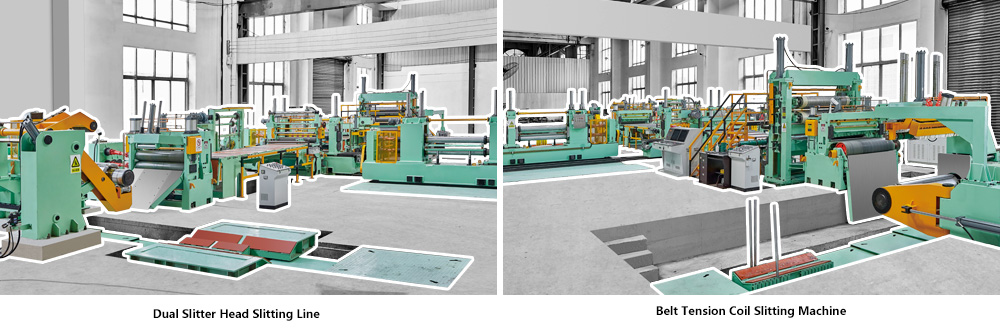

For customers with more demanding production requirements, KINGREAL SLITTING offers high-performance machines, such as double slitter head metal coil slitters, which allow for higher throughput and versatility, and metal coil slitters with belt tension control, which help maintain consistent tension during the slitting process, ensuring smoother and more accurate cuts. With these tailored solutions, KINGREAL SLITTING meets the specific needs of customers, improving their production efficiency and product quality.

Consideration of Choosing Steel Coil Slitting Machine

There are many metal coil slitters on the market, and choosing a suitable steel coil slitting machine is a crucial step in the production process for many companies. So, how to choose a steel coil slitting machine that suits your production needs? As a manufacturer with more than 20 years of rich experience in the metal coil slitter manufacturing industry, KINGREAL SLITTING will explain in detail the key factors that need to be considered when choosing a metal coil slitter.

① Production needs

When choosing a metal coil slitter, the most important thing is to clarify your production needs. Although there are various metal coil slitters with different functions and specifications on the market, if the functions and parameters of the machine do not match the actual needs, no matter how many additional functions are added, it will be in vain. For example, some companies may need high-precision slitting, while others focus more on high efficiency. Therefore, the first thing to consider when choosing a steel coil slitting machine is whether the machine can meet the specific production requirements of the company.

KINGREAL SLITTING provides steel coil slitting machine services customized according to customer drawings, which can ensure that the machine is fully adapted to the customer's production environment and ensure smooth use. Customized steel coil slitting machines can better improve production efficiency and reduce operating difficulties, which is a major advantage of KINGREAL SLITTING.

② Quality

The quality of the steel coil slitting machinedirectly affects the production efficiency and economic benefits of the enterprise. A high-quality metal coil slitter not only has a long service life, but also runs more smoothly during operation, thereby greatly reducing downtime and maintenance costs caused by machine failures. KINGREAL SLITTING is extremely rigorous in the manufacturing process of the metal coil slitter.

KINGREAL SLITTING start with the selection of raw materials and strictly control them. All raw materials will be tested, including hardness, wear resistance and other indicators to ensure that they meet the standards for metal coil slitter manufacturing. If the material does not meet the requirements, KINGREAL SLITTING will never use it, but return it to the supplier. During the production process, the staff strictly controls the quality of each component, even a small screw, and requires it to fully match the machine, rather than just barely. It is precisely because of this rigorous attitude that KINGREAL SLITTING's metal coil slitter has won unanimous praise from customers in the market.

③ After-sales service

When choosing a steel coil slitting machine, in addition to caring about the performance and quality of the machine itself, you also need to pay attention to the manufacturer's after-sales service. Because after purchasing a steel coil slitting machine, it involves the installation, commissioning, operation training and later repair of the machine, all of which require professional support from the manufacturer. KINGREAL SLITTING provides a full range of after-sales services to ensure that customers will not encounter difficulties during use after purchase. KINGREAL SLITTING provides customers with installation and commissioning support, and conduct operation training through online meetings or by sending engineers to the customer's site. When the machine fails, our technical team can respond quickly, locate the problem and propose solutions to avoid customers stopping production due to slitting machine failure. Customers who have worked with us have expressed their satisfaction with our after-sales service and believe that our technical support can maximize the stable operation of the production line.

④ Price

The price of the steel coil slitting machine is affected by multiple factors such as brand, model, function, quality, etc. Therefore, when evaluating the price, enterprises should comprehensively consider the following points:

● Budget: Set a reasonable budget range based on the company's financial situation and investment return expectations. Excessive investment may lead to financial pressure, while too low a budget may affect the performance and quality of the machine.

● Cost-effectiveness analysis: In addition to the initial price of the machine, the company should also consider the long-term operating costs, including energy consumption, maintenance, and depreciation of the machine. By analyzing these factors, the overall economic feasibility of the slitting machine is evaluated.

● Market research: Conduct market research, understand the quotations of different suppliers, compare the cost-effectiveness of different brands and models, avoid quotations that are too high or too low, and ensure that the most suitable products and services are obtained.

When choosing a metal coil slitter, enterprises should not only pay attention to the quality, function and price of the machine itself, but also comprehensively consider production needs, after-sales service and other factors.

KINGREAL SLITTING has rich experience and technical advantages in the field of metal coil slitter manufacturing, and is committed to providing customers with high-quality, customized slitting solutions, while providing comprehensive after-sales support.