"Fully automatic cut to length machines are widely used in the sheet metal processing industry, capable of precisely cutting large metal coils to customer specifications.

This automatic cut to length line not only reduces the burden of manual labor but also improves production efficiency and cutting accuracy.

KINGREAL SLITTING can design a variety of fully automatic cut to length machines with varying configurations and performance to meet diverse customer needs, tailored to specific production requirements and drawings."

〡Workflow of Automatic Cut to Length Line

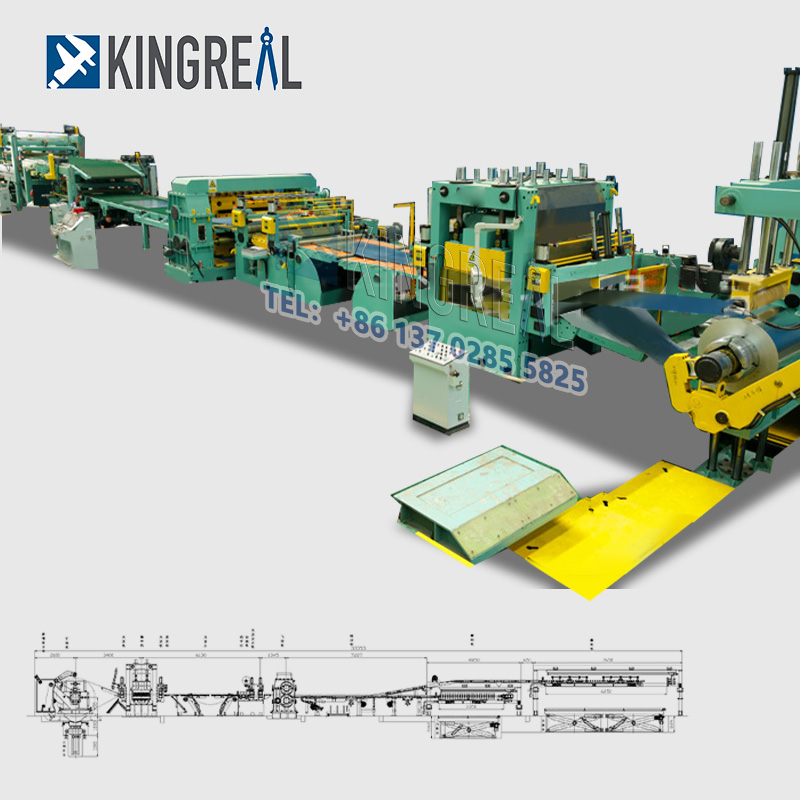

Coil Lifter ---- Decoiler ---- Snubber Roller + Pinch Roller + Pre-Leveling Machine ---- Loop Bridge ---- Side Guide ---- Precision 5-Roller Leveling Machine (Servo Control) ---- High-Speed Shear ---- Conveyor ---- Auto Stacker + X-Lifting Platform + Unload Cart

〡Technical Parameters of Automatic Cut to Length Machine

·Variable belt length: up to 14 meters, accommodating various metal coil specifications.

·Hydraulic cutting device: Ensures cutting accuracy and efficiency.

·Steel Rule Die Cutting: Supports back-side cutting for increased cutting flexibility. Quick-change tool holders facilitate operation and maintenance, saving time.

·Adjustable splice angle: Adjustable between 90° and 45° to meet diverse cutting requirements.

·Pneumatic clamp: A pneumatic clamp guides the material out of the cutting station, enhancing operational safety.

·Pneumatic brake with automatic adjustment: Ensures material stability during the production process.

·Fully automatic working cycle: Operation is simple, requiring only supervision of the production line.

·Easy-to-use touchscreen: A user-friendly interface makes operation more intuitive.

〡Features of Automatic Cut to Length Lines

(1)Coil trolley/coil elevator for automatic cut to length line

The coordinated operation of the coil trolley and coil elevator greatly simplifies the coil loading process. The coil trolley is electrically driven and moves back and forth on rails, easily moving the coil into the decoiler's jaws.

The coil elevator, driven up and down by a hydraulic cylinder, ensures coil stability during loading. This design effectively prevents the coil from tilting or slipping, reducing the risk of accidents during operation. Furthermore, the aligning axes of the coil trolley and elevator make the loading process smoother and reduce material loss.

(2)Decoiler/\decoil unit for automatic cut to length machine

KINGREAL SLITTING decoiler features a flexible design, allowing multiple coils to be pre-placed at the loading station. This feature is particularly important for high-volume automatic cut to length lines, effectively reducing downtime and improving production efficiency.

The decoil unit is available in single- or dual-head configurations, allowing for flexible adjustment based on production needs and ensuring more efficient operation.

The decoiler design not only considers coil loading and unwinding but also emphasizes operational safety. The rational mechanical structure ensures ease of use for operators, reducing the risk of accidents caused by improper operation.

(3)Buffer and support table assembly for automatic cut to length line

The buffer and support table assembly plays a vital role in fully automatic cut to length machines. The buffer compresses the outer diameter of the coil, ensuring that the coil does not sag during cutting, resulting in uneven cuts.

This assembly can be operated hydraulically or pneumatically to meet different production requirements. The hydraulically operated support table facilitates smooth sheet feeding into the straightener, ensuring a smooth and unobstructed cutting process throughout the entire automatic cut to length line.

The support table is designed with the characteristics of various materials in mind, allowing for adjustments to accommodate metal coils of varying thicknesses, ensuring precise and high-quality cutting.

(4)Straightener for automatic cut to length machine

KINGREAL SLITTING straighteners are available in a variety of designs, including 2HI, 4HI, and 6HI configurations. The rollers are hardened to a hardness of HRC 55-60, offering excellent wear resistance and a long service life. This ensures the straightener's stability and reliability over long-term use.

The straightener's design ensures optimal sheet condition before entering the cutting unit, minimizing cutting errors caused by uneven material. The multi-roller design allows for effective straightening of coils of varying thicknesses and materials, ensuring flexibility and adaptability of the automatic cut to length line, allowing customers to achieve high-quality cut products tailored to their specific production needs.

(5)CNC servo roller feeder/encoder for automatic cut to length machine

The feeding system of the fully automatic cut to length line utilizes an advanced CNC servo roller feeder, coupled with an encoder, to achieve high-precision feeding. Driven by an AC servo motor, this system ensures precise feeding according to the set length. Its rapid positioning capability significantly improves production efficiency.

The feed roller adjustment is controlled by a pneumatic cylinder, adapting to the varying needs of the automatic cut to length line and ensuring efficient and stable operation for both long and short lengths. When the automatic cut to length machine is running tight, the encoder assembly automatically measures length to ensure accurate cutting.

(6)Shearing unit for automatic cut to length line

The shearing unit is the core component of the fully automatic cut to length machine, responsible for cutting coils into sheets of desired length.

KINGREAL SLITTING precision design of the shearing unit for automatic cut to length lines ensures a smoother cutting process, reduces burrs and deformation on the cut edges, and improves overall product quality.

Through its rational layout, the shearing unit seamlessly integrates with other components, ensuring efficient operation of the entire automatic cut to length line.

(7)Conveyor unit for automatic cut to length machine

The conveyor unit transports cut sheets to the subsequent stacking unit, ensuring a smooth production process. KINGREAL SLITTING conveyor unit is rationally designed and can be flexibly adjusted to different production environments, ensuring that the sheets are not damaged during conveying.

The stability of the conveyor system ensures the efficient operation of the entire automatic cut to length line, effectively preventing material loss caused by bumps during conveying. Furthermore, the conveyor unit is designed with safety in mind, ensuring that operators are protected from accidental injuries during operation.

(8)Stacking unit for automatic cut to length machine

The stacking unit is responsible for automatically stacking the cut sheets. KINGREAL SLITTING stacking unit can be equipped with either a pneumatic or electromagnetic stacking system, and features a scratch-resistant blower, ensuring a smooth, scratch-free surface after stacking.

Furthermore, the ability to stack the sheets in both longitudinal and transverse directions allows the stacking unit to adapt to different customer needs, enhancing the flexibility of the automatic cut to length line.