"Stainless steel slitting machine slits broad metal coils into certain widths in contemporary metal manufacturing using a continuous, high-speed slitting technique. From tank trailer sidewalls to little electronic components, this procedure satisfies a broad spectrum of manufacturing demands.

Stainless steel slitting lines are critical tools in the production process, whether making vehicle panels, refrigerator housings, or furniture frames, because of their accuracy and efficiency."

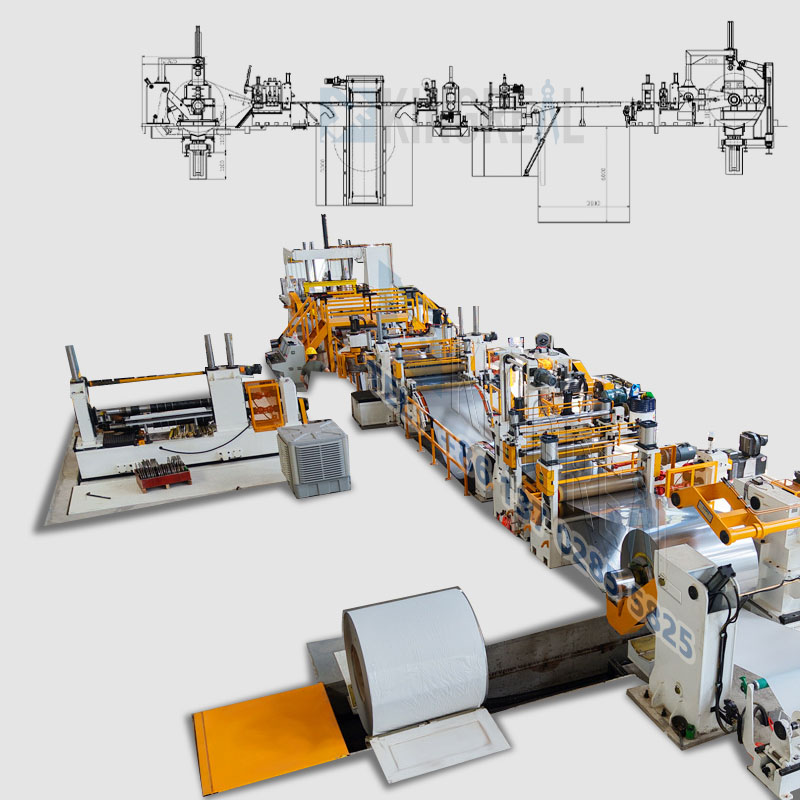

〡What is a Stainless Steel Slitting Machine?

A stainless steel slitting line is specifically designed for slitting metal coils. It uses strong, rotating blades to continuously cut metal material while feeding at high speeds. More precisely, a stainless steel slitting machine creates a blade axis from circular slitting blades set above and below the unwinding metal strip. Usually spinning thousands of times per minute, these sharp blades are meant to cleanly shear steel, stainless steel, aluminum, and a number of metal alloys.

Through a feed mechanism, the coil is fed into the stainless steel slitting machine where the blades cut the metal strips at a specified angle and speed.This method guarantees great product quality since the resulting metal strips fulfill precise width and thickness tolerances as well as being very effective.

〡Importance of Stainless Steel Slitting Line

The importance of stainless steel slitting machines in metal manufacturing is self-evident.

First, they significantly improve material utilization. Stainless steel slitting lines minimize metal waste by exact slitting, therefore allowing producers to more wisely utilize raw materials.

Second, as the market for bespoke metal components expands, the precision cutting of stainless steel slitting machines guarantees that every thin strip fulfills particular requirements, therefore greatly increasing production efficiency.

Moreover, the flexibility of stainless steel slitting lines enables producers to swiftly adjust to shifting market needs and satisfy several production needs.

〡Different Types of Stainless Steel Slitting Machines

Based on customer production requirements, KINGREAL SLITTING designs a variety of stainless steel slitting line types to meet the diverse needs of manufacturers. Each stainless steel slitting machine is designed for specific applications, ensuring optimal performance and productivity.

(1)High speed stainless steel slitting line

With production rates of up to 230 m/min, KINGREAL SLITTING stainless steel slitting machines offer the quickest setup and changeover times in the market.These high-speed stainless steel slitting lines can process great volumes of metal goods, so boosting production output and lowering lead times, therefore helping companies to meet the most demanding deadlines.

Highly adaptable as well, these stainless steel slitting line provide several slitting head types—including CNC fully automated setups—to fit different production demands.

(2)Light gauge slitting machine

The light gauge slitting machine can process metal materials ranging from 0.2 to 3 mm in thickness. This advanced machine quickly disassembles the primary coil and delivers a product ready for construction, streamlining the supply chain and reducing lead times.

KINGREAL SLITTING light gauge slitting machine is designed to handle a variety of lightweight materials, making it a versatile tool that adapts to diverse production needs. From short to long runs, from thin aluminum sheets to galvanized steel coils, these light gauge slitting machine s consistently deliver consistent performance.

In addition, the light gauge slitting machine is equipped with robust guards and advanced safety features to ensure operator safety.

(3)Heavy gauge slitting machine

KINGREAL SLITTING heavy gauge slitting machine is designed specifically for processing metal coils ranging from 6 to 16 mm in thickness and is suitable for industries such as automotive, construction, and shipbuilding.

Heavy gauge slitting machine is a great match because these sectors call for exceptionally strong and durable metal parts.Their capacity to handle hot-rolled steel, stainless steel, and thick aluminum makes them appropriate for producers with varied manufacturing demands.

The high-precision slitting head with heavy gauge slitting machines also lowers tool vibration, therefore guaranteeing a more constant blade gap and more exact slitting outcomes.

〡Workflow of Stainless Steel Slitting Machine

The stainless steel slitting line workflow can be divided into several key steps:

-Feeding For Slitting Line: Wide metal coils are fed into the stainless steel slitting machine via an automatic feeder. This process is precisely controlled by sensors and a control system to ensure stable coil feeding.

-Slitting Machine: The metal coils are cut by the blades. The blade of the stainless steel slitting line ensures that every metal strip satisfies the stated width and thickness criteria by helping it to keep slitting accuracy at high speeds.

-Recoiling For Slitting Machine: After slitting, the stainless steel slitting machine reels the cut metal strips. Many times, this process includes an automatic reeling system for simpler storage and travel.

-Quality Inspection: Real-time monitoring of slitting accuracy and product quality is provided by a quality inspection system on the stainless steel slitting line all along the manufacturing process.

This process helps producers to quickly spot and fix any problems, hence guaranteeing a great yield of finished goods.

〡Applications of Stainless Steel Slitting Machines

Because of their effective manufacturing and accurate slitting capabilities, stainless steel slitting lines are generally used in several sectors, including:

-Stainless steel slitting machine in transportation industry: Used in the production of metal parts for cars, trailers, and containers, stainless steel slitting machines' effective slitting capacity guarantees the quality and effectiveness of these components.

-Stainless steel slitting line in home appliance industry: Stainless steel slitting machines supply the necessary metal strips to satisfy the demands of several types and designs in housing manufacture for appliances like washing machines and refrigerators.

-Stainless steel slitting line in furniture manufacturing: In the production of furniture such as tables, cabinets, and monitors, stainless steel slitting machines provide manufacturers with reliable metal components, ensuring durability and aesthetics.

-Stainless steel slitting line in electronics: Stainless steel slitting machines provide precise metal slitting in the manufacture of electronic housings, frames, and components, ensuring product quality and performance.

-Stainless steel slitting line in signage production: Stainless steel slitting machines also play a vital role in the production of building packaging and billboards, providing high-quality metal materials and ensuring the durability of signage.