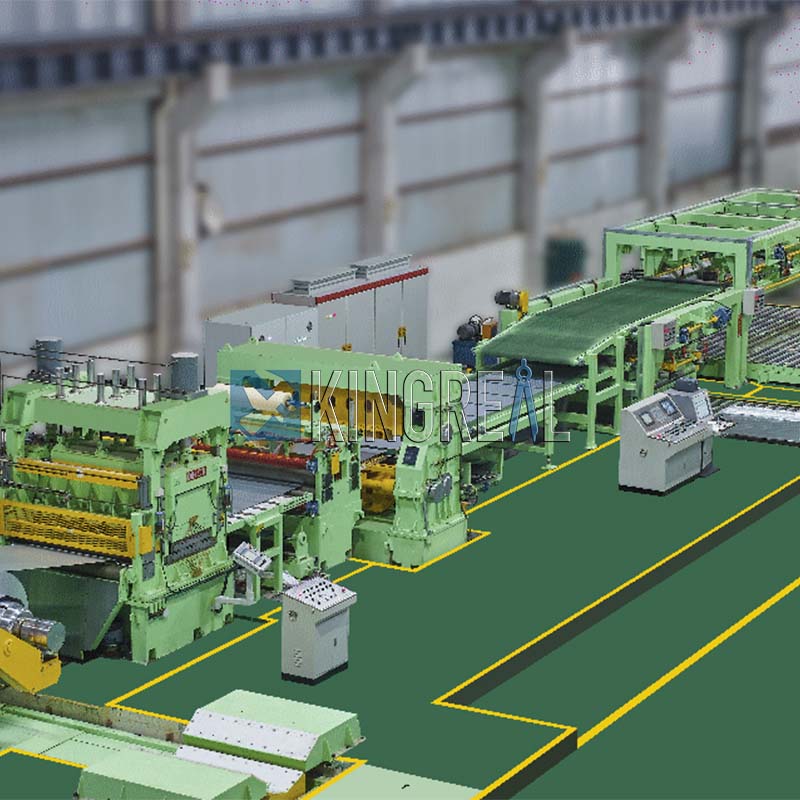

In the metal processing industry, efficiency and precision are key to producing high-quality metal products and minimizing waste and energy consumption. Fly shearing cut to length machine is one of the advanced technologies driving this progress. Fly shearing cut to length line plays a vital role in optimizing the shearing process, ensuring stable product quality and operational efficiency. As the most in-demand type of fly shearing cut to length machine in modern metal cut to length lines, fly shearing cut to length lines provide customers with a solution that can accurately and efficiently cut metal materials even at high speeds.

What is a Fly Shearing Cut to Length Machine?

A fly shearing cut to length line is an efficient metal cutting equipment designed to achieve fast and precise shearing. Its core feature is that the fly shearing cut to length machine assembly allows the shearing machine to accelerate and synchronize with the strip speed, and the material can be sheared without stopping the feed. This design eliminates the downtime required for cumulative shearing cycles, allowing the entire coil of strip to be processed efficiently. Fly shearing cut to length line are usually installed on continuous processing equipment, such as casting machines, further improving production efficiency. |  |

Key Components of Fly Shearing Cut to Length Line

The efficiency of fly shearing cut to length machines lies in their advanced design and carefully coordinated components. Here are some key components:

1. Shear blade for fly shearing cut to length line

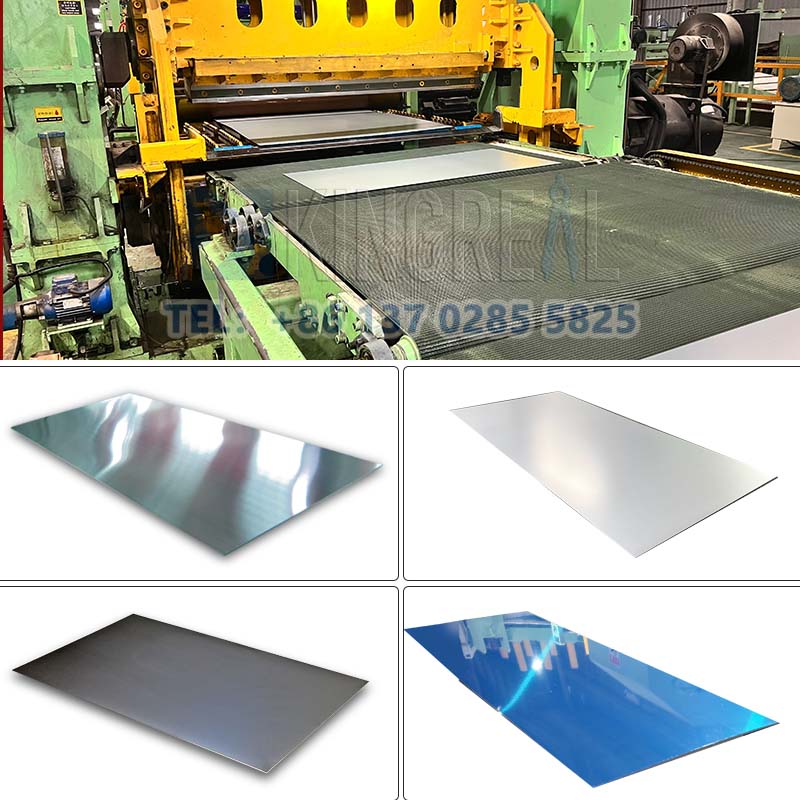

The shear blade is one of the core components of the fly shearing cut to length line. It is made of highly durable materials and is designed to withstand the high temperatures and stresses generated during cutting. The design of the blade not only affects the shearing quality, but also directly affects the production efficiency.

2. Stacking table for fly shearing cut to length machine

The stacking table is responsible for automatically stacking the metal sheets, reducing the need for manual intervention and saving labor costs. Through automated operation, the stacking table ensures a steady supply and consistency of materials.

3. Drive mechanism for fly shearing cut to length machine

The driving mechanism of the fly shearing cut to length line usually adopts an integrated motor system, which is synchronized with the rolling mill speed to ensure the accuracy of the shearing. With precise speed control, the fly shearing cut to length machine can maintain high-quality shearing results at high production speeds.

4. Guide system for fly shearing cut to length line

The guide system ensures that the metal remains correctly aligned when entering the shearing area. The perfect design of this system reduces the deviation of the material during the shearing process and further improves the shearing accuracy.

5. Control system for fly shearing cut to length machine

Modern fly shearing cut to length lines are equipped with advanced sensors and control units that can monitor and adjust parameters in real time. This system ensures accuracy and efficiency during the shearing process, making the production process smoother.

Other Metal Cut to Length Lines with Other Shearing Types

In the field of metal processing, in addition to the fly shearing cut to length machine, there are several other cut to length lines with other shearing types:

Rotary shearing cut to length line: This rotary shearing cut to length line has a production speed of up to 80m/min and is suitable for large-scale production. It can realize continuous feeding cutting, thereby minimizing the indentation of the plate when stopping and starting.

Fixed shearing cut to length line: Its production speed can reach up to 50m/min, which is more economical than other metal cut to length lines.

Swing shearing cut to length line: It can also reach a production speed of 80m/min, successfully realizing continuous swing shearing production without stopping the production process, and can shear non-standard metal plates (trapezoidal metal plates).

Different types of metal cut to length lines have their own advantages. Choosing the right metal cut to length machine can effectively improve production efficiency and product quality.

How Fly Shearing Cut to Length Machine Works?

The success of the fly shearing cut to length line lies in its unparalleled speed synchronization. As the material moves continuously on the production line, the fly shearing cut to length machine is seamlessly integrated through the acceleration or deceleration slide to ensure precise cutting without stopping the production process. This design enables the fly shearing cut to length line to maintain high precision at high speeds, greatly improving production efficiency. Technological Advances and Control Software With the continuous advancement of technology, the control system of the fly shearing cut to length machine has also undergone significant changes. Industry leaders such as KINGREAL SLITTING have led the transition from manual control systems to automated control systems, focusing on precision and efficiency. Its commitment to innovation is reflected in the following aspects: ·Advanced software: extremely precise synchronous cutting is achieved, reducing the need for human intervention. ·Significantly reduce errors: ensure consistent product quality and improve customer satisfaction. ·Simplified operation: through the automation system, the workload of operators is greatly reduced, thereby improving productivity and reducing waste. |  |

Advantages of Fly Shearing Cut to Length Line

1. Precise length cutting The fly shearing cut to length machine ensures that the material is cut to a precise length. This integrated design improves productivity and quality by ensuring the consistency of material length. 2. Uniform shearing The fly shearing cut to length line can cut the material evenly, which is essential to maintaining the high quality standards of the final product. Uniform shearing not only improves product quality, but also reduces the difficulty of subsequent processing. 3. Increase production speed Since the fly shearing cut to length machine can cut without interrupting the flow of materials, it can speed up production, reduce waste and improve overall process efficiency. This design is particularly suitable for large-scale production needs. 4. Fully automated operation Modern fly shearing cut to length lines are usually equipped with feeding trolleys and stacking tables to achieve fully automated operation. This not only improves production efficiency, but also reduces labor costs and enhances the competitiveness of enterprises. |  |