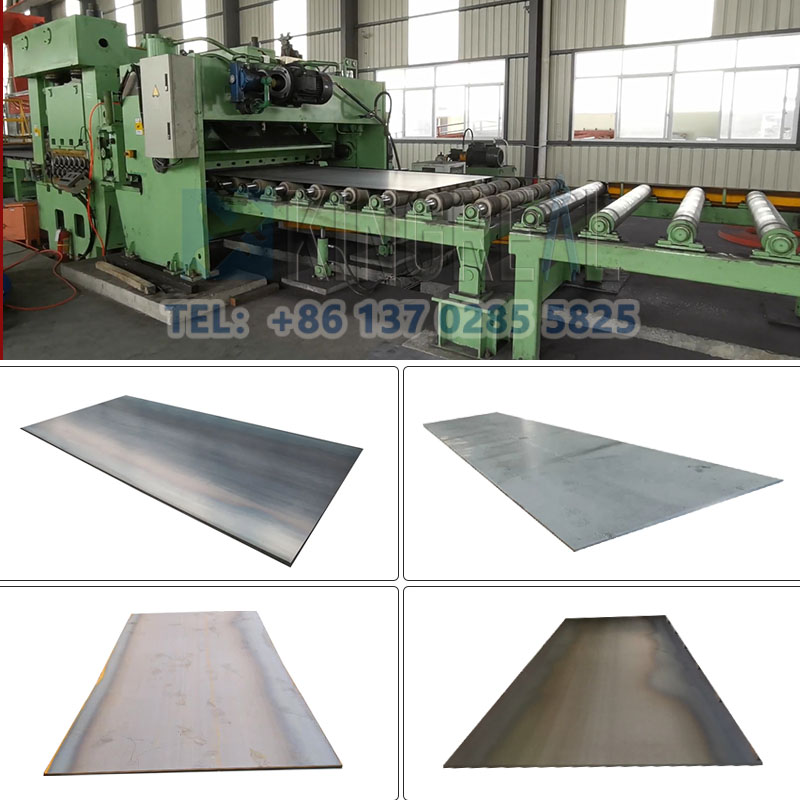

KINGREAL SLITTING heavy gauge cut to length machine can accurately shear metal coils of different materials such as stainless steel, copper, aluminum, cold rolling, hot rolling, etc. in the thickness range of 6-20MM. There are different ways to classify thick plates. In addition to being classified by size, thick plates cut by heavy duty cut to length machine are also classified by strength, chemical composition, purpose and delivery status. According to strength classification, the lower limit of tensile strength is generally used for classification, and high-strength steel plates with a tensile strength of more than 50kgf/cm are called high-strength steel plates. According to chemical composition, they are divided into ordinary steel plates and special steel plates, the latter including stainless steel plates and composite steel plates. According to use, they are roughly divided into shipbuilding steel plates, welded structure steel plates, boiler and pressure vessel steel plates, low-temperature steel plates, corrosion-resistant steel plates, steel plates for welded pipes, and steel plates for special purposes. According to delivery status, they are divided into three types: rolled steel plates, heat-treated steel plates, and shot-blasted and coated steel plates. Due to the needs of large structures and shipbuilding, the output of shot-blasted and coated steel plates has increased year by year. |  |

Parameters of Heavy Gauge Cut to Length Machine

| Machine Type | Heavy Duty Cut To Length Machine |

| Material | Stainless steel, copper strip, silicon steel, cold rolled and hot rolled steel, etc. |

| Max Coil Thickness | 20mm |

| Max Coil Weight | 3600mm |

| Max Coil Height | 30 Ton |

| Max Cutting Length | 24m |

| Cutting Speed | 60m/min |

| Cut Tolerance | ±0.01mm |

Diverse Heavy Duty Cut to Length Machine Manufacturing Solutions

1

Heavy Gauge Cut to Length Line Options by System

KINGREAL SLITTING heavy duty cut to length machine offers different combinations depending on the required metal cutting capacity, the range of processed raw materials, and the customer's budget.

KINGREAL SLITTING is always committed to providing customers with the best solutions.

2

Heavy Gauge Cut to Length Machine with Pit System

This heavy duty cut to length machine system offers a more professional solution with higher production capacity and the ability to handle heavy materials.

Due to the pit operation system, KINGREAL SLITTING heavy gauge cut to length machine system of course requires construction. In addition, on this heavy duty cut to length machine of ours, the straightener and feeder units are separate. The heavy gauge cut to length machine with pit system takes up more space in the customer's factory and is suitable for specialized and high-capacity production.

3

Heavy Duty Cut to Length Line with Rotary Shear and Straightener

This is KINGREAL SLITTING most advanced heavy gauge cut to length machine system. It is able to achieve perfect capacity due to the advantages of rotary shear or flying shear and straightener.

The straightener can even straighten severely damaged coils, and the straightening level of this machine model has reached a perfect level. Due to its high steel cutting capacity and the advantage of straightening damaged coils, it is very suitable for steel dealers. This heavy duty cut to length machine can reach a considerable working speed. In addition, the correction of damaged coils also brings great advantages to KINGREAL SLITTING customers.

Applications of Heavy Gauge Cut to Length Machines

Heavy duty cut to length machines are mainly used in construction engineering, machinery manufacturing, container manufacturing, shipbuilding, bridge construction, etc. It can also be used to manufacture various containers, furnace shells, furnace plates, bridges and automobile static steel plates, low alloy steel plates, shipbuilding steel plates, boiler steel plates, pressure vessel steel plates, patterned steel plates, automobile beam steel plates, certain parts of tractors and welded components, etc.

(I) Bridge steel plates: Steel plates used for large railway bridges, which are required to withstand dynamic loads, impacts, vibrations, corrosion resistance, etc., such as: Q235q, Q345q, etc.

(II) Shipbuilding steel plates: Used to manufacture marine and inland ship hulls, requiring high strength, plasticity, toughness, cold bending performance, welding performance, and corrosion resistance. Such as: A32, D32, A36, D36, etc. Boiler steel plate (boiler plate): used to manufacture various boilers and important accessories. Since boiler steel plates work under medium temperature (below 350°C) and high pressure, in addition to bearing high pressure, they are also subject to impact, fatigue load and water and gas corrosion. They are required to ensure a certain strength and have good welding and cold bending performance, such as: Q245R, etc.

(III) Steel plates for pressure vessels: mainly used to manufacture pressure vessels and other similar equipment for petroleum, chemical gas separation and gas storage and transportation. The general working pressure is from normal pressure to 320kg/cm2 or even to 630kg/cm2, and the temperature is in the range of -20-450°C. In addition to having a certain strength and good plasticity and toughness, the container steel plate must also have good cold bending and welding performance, such as: Q245R, Q345R, 14Cr1MoR, 15CrMoR, etc.

(IV) Steel for automobile beams: low-alloy hot-rolled steel plates with a thickness of 2.5-12.0mm are used to manufacture automobile beams (longitudinal beams and cross beams). Due to the complex shape of automobile beams, in addition to requiring high strength and cold bending performance, good stamping performance is also required.