In the global power equipment manufacturing industry, silicon steel, as an important electrical material, is widely used in the manufacture of transformers, motors and other equipment due to its excellent magnetic conductivity and low loss characteristics. KINGREAL SLITTING is honored to have reached a friendly cooperation with a Turkish customer and successfully provided it with a high-performance Silicon Coil Slitting Line. This project is not only a milestone in the cooperation between the two parties, but also provides an effective solution for the customer's production needs.

Background introduction of Turkish customers

This Turkish customer is a company specializing in power equipment manufacturing and is committed to providing high-quality transformer products. In order to meet the market's growing demand for high-performance transformers, they decided to invest in a CRGO / CRNGO Silicon Steel Slitting Line to achieve higher efficiency and better product quality in the production process. The performance of silicon steel directly affects the efficiency and stability of the transformer, so the customer's requirements for the Silicon Steel Slitting Machine are very strict. In the initial communication with the Turkish customer, KINGREAL SLITTING learned that they hope to achieve the following goals through this CRGO / CRNGO Silicon Steel Slitting Line: Improve production efficiency: reduce manual intervention and increase production speed through automated slitting process. Ensure product quality: meet strict material and dimensional accuracy requirements, and ensure the magnetic conductivity and low loss characteristics of the final product. Flexible production capacity: Ability to process silicon steel materials of different thicknesses and widths to adapt to changes in market demand. |  |

Importance of Silicon Steel Slitting Machine

Silicon Coil Slitting Line is a key link in the production process of silicon steel, and its quality directly affects the performance and application of the product. The following are the key requirements for CRGO / CRNGO Silicon Steel Slitting Line:

1. Material requirements

The silicon steel materials used for slitting must meet national standards or customer-specific technical specifications, and have good magnetic permeability and low loss characteristics. During this process, Turkish customers particularly emphasized that there must be no defects such as scratches, dents, oxidation and oil stains on the surface of the material. These defects may lead to a decline in product performance and even affect the efficiency of the final transformer.

At the beginning of the project, KINGREAL SLITTING engineers had in-depth communication with Turkish customers to ensure that their material selection met the project requirements. KINGREAL SLITTING also provided a detailed material testing plan to ensure that each batch of materials can meet high standards.

2. Dimensional accuracy

The silicon steel strip after slitting must meet the dimensional accuracy requirements of Turkish customers, including width, thickness and length. KINGREAL SLITTING discussed with the customer the reasonable range of dimensional deviations to ensure that the Silicon Steel Slitting Machine can accurately control these parameters to meet the design requirements.

When visiting KINGREAL SLITTING production facilities, the Turkish customer expressed high recognition of KINGREAL SLITTING technical capabilities in dimensional control. KINGREAL SLITTING engineers demonstrated the adjustment function of the CRGO / CRNGO Silicon Steel Slitting Line and emphasized how to achieve the required dimensional accuracy through precise settings.

3. Surface quality

The surface quality of silicon steel strip is crucial to its magnetic permeability and loss characteristics. Therefore, the surface quality must be strictly controlled during the processing process to ensure that the surface of the final product is flat and smooth, without scratches, dents and other defects. In the communication with the Turkish customer, KINGREAL SLITTING explained our surface treatment process in detail to ensure that they are confident in the quality of the CRGO / CRNGO Silicon Steel Slitting Line.

4. Edge straightness

Edge straightness is an important factor affecting the processing and forming of silicon steel strip. Turkish customers require that the edges of silicon steel strips remain straight without obvious defects such as curling burrs and cracks. KINGREAL SLITTING engineers specially designed the edge control system of the Silicon Steel Slitting Machine to ensure accurate edge processing during the processing.

During the factory visit of the Turkish customer, KINGREAL SLITTING demonstrated the practical application of this technology. The Turkish customer expressed strong interest in this and believed that this design would greatly improve the overall quality of their products.

KINGREAL SLITTING communicated with Turkish customers about Silicon Coil Slitting Line

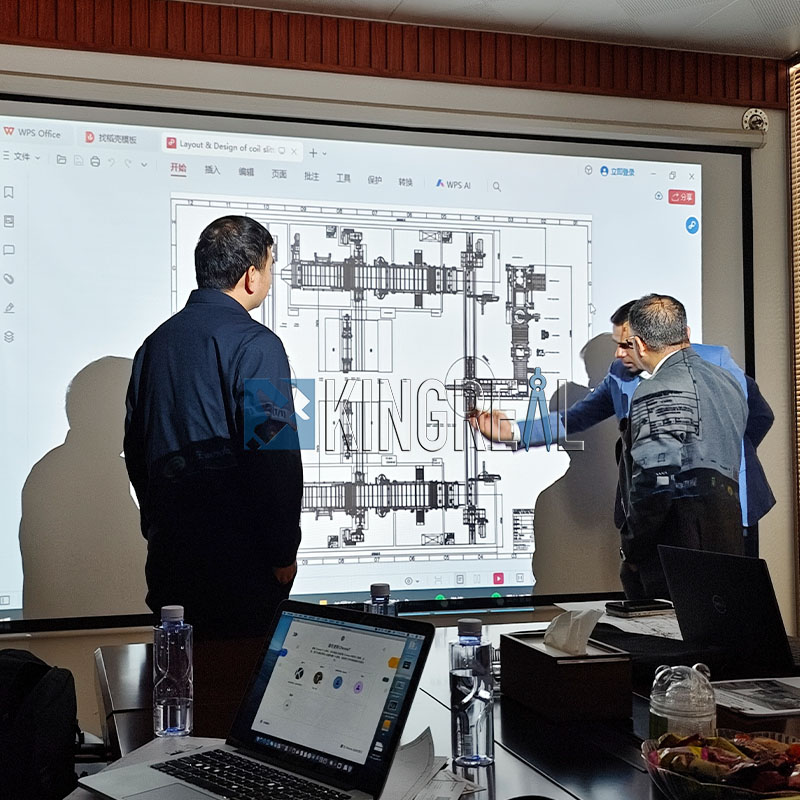

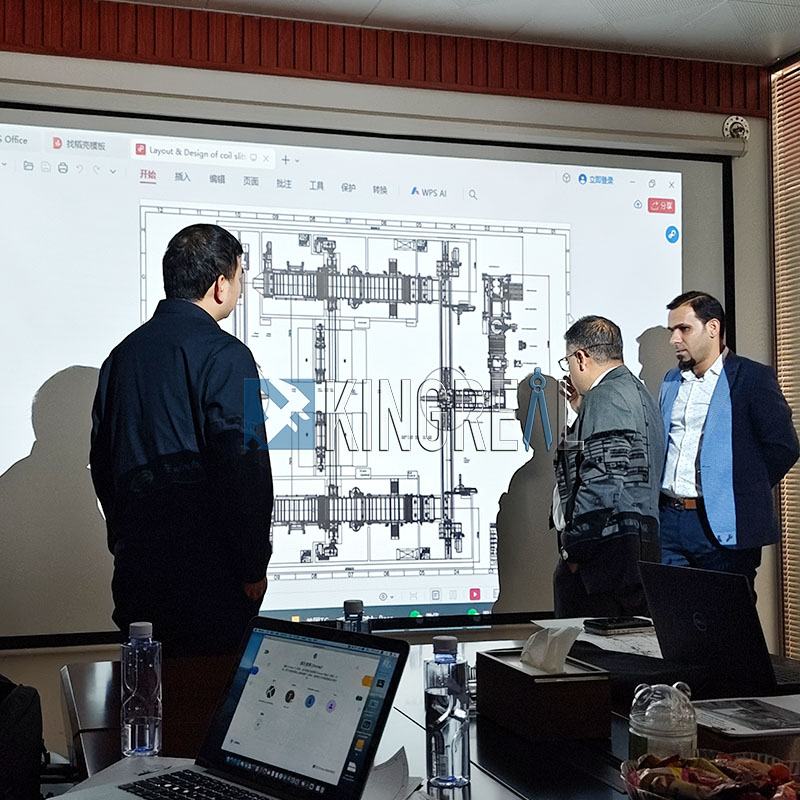

Throughout the project, KINGREAL SLITTING engineering team maintained close communication with the customer. KINGREAL SLITTING engineers were not only responsible for the design and manufacture of the CRGO / CRNGO Silicon Steel Slitting Line, but also actively participated in the inspection and discussion of the customer's factory.

When the Turkish customer visited KINGREAL SLITTING factory for the first time, KINGREAL SLITTING staff introduced the working principle and production process of the silicon steel slitting machine in detail. The Turkish customer appreciated KINGREAL SLITTING production facilities and technical capabilities, and had an in-depth discussion on the operation process of the CRGO / CRNGO Silicon Steel Slitting Line. KINGREAL SLITTING engineers patiently answered various questions from Turkish customers to ensure that they were confident in the upcoming cooperation.

When discussing the Silicon Coil Slitting Line manufacturing plan, KINGREAL SLITTING optimized the design of the Silicon Steel Slitting Machine according to the specific needs of Turkish customers. After many communications and adjustments, KINGREAL SLITTING finally determined the silicon steel slitting machine configuration that suits the customer's needs. KINGREAL SLITTING particularly emphasized the flexibility of the CRGO / CRNGO Silicon Steel Slitting Line to ensure that it can meet the production needs that may increase in the future.

Project Implementation and Equipment Delivery

After several months of close cooperation, KINGREAL SLITTING finally completed the production of silicon steel slitting machines for Turkish customers. KINGREAL SLITTING strictly produces in accordance with the technical requirements and delivery schedule of Turkish customers to ensure that each CRGO / CRNGO Silicon Steel Slitting Line can meet high standards.

Before the Silicon Steel Slitting Machine was about to be delivered, KINGREAL SLITTING engineering team conducted comprehensive equipment testing and debugging to ensure that all functions were operating normally. On the day of the Silicon Steel Slitting Machine delivery, KINGREAL SLITTING technical team personally accompanied the Turkish customers for on-site acceptance to ensure that they were satisfied with the performance and quality of the CRGO / CRNGO Silicon Steel Slitting Line.

Feedback and Follow-up Support from Turkish Customers

During the acceptance process, Turkish customers spoke highly of the overall performance of the Silicon Coil Slitting Line, especially the improvement in production efficiency and product quality. They said that this silicon steel slitting machine will greatly enhance their production capacity and help them maintain competitiveness in the market.

After the delivery of the CRGO / CRNGO Silicon Steel Slitting Line, KINGREAL SLITTING did not end its cooperation with the customer. KINGREAL SLITTING promises to provide continuous technical support and maintenance services to ensure the stability and efficiency of the Silicon Steel Slitting Machine in daily production. KINGREAL SLITTING technical team will keep in touch with customers regularly, promptly solve the problems they encounter during use, and provide relevant technical training.