Italy 850MM Coil Slitting Line

- Coil Thickness: 0.3-2MM

-Coil Width: 850MM

- Coil Material: Galvanized sheet

Customer Background and Needs

KINGREAL SLITTING recently engaged with a customer from the United States through its official website. This customer primarily targets the European markets, which demand exceptional precision and reliability in metal processing equipment. The customer expressed specific requirements for a coil slitting machine that could achieve extremely high accuracy, ensuring compliance with the stringent quality standards of the European market. Additionally, the customer required the coil slitting line to be versatile enough to handle a wide range of metal raw materials, including GI steel , cold-rolled steel, and PPGI. The coil slitting machine also needed to process wide-width metal coils while maintaining high-speed production capabilities to meet the large-scale production demands of the customer's factory.

These unique requirements presented a significant challenge: delivering a high-performance, multi-functional coil slitting solution tailored to the customer's complex and diverse needs.

Customized Solutions

Upon receiving the customer’s technical drawings and specifications, the engineering team at KINGREAL SLITTING initiated a series of in-depth discussions to clarify and refine the production requirements. Through detailed communication and iterative design reviews, the team gained a comprehensive understanding of the customer’s expectations.

Based on these insights, KINGREAL SLITTING designed and manufactured a fully customized, high-speed coil slitting machine that addressed all the customer's demands. KINGREAL SLITTING coil slitting machine was equipped with the following advanced features:

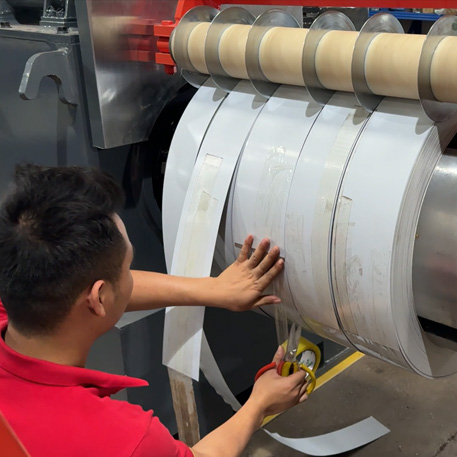

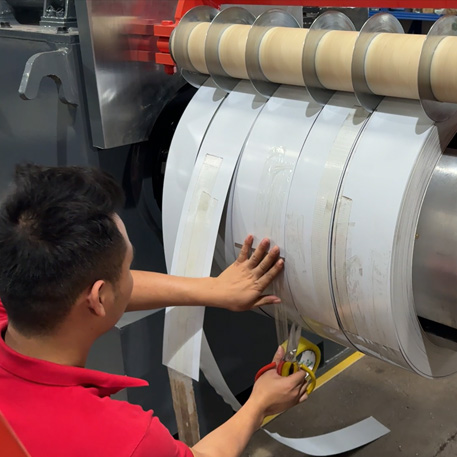

1. Multi-Material Compatibility: KINGREAL SLITTING coil slitting line supports the slitting of various metal raw materials, including GI steel, cold-rolled steel, and PPGI. It can handle material thicknesses ranging from 0.4mm to 5mm, ensuring versatility and adaptability for different production scenarios.

2. Large Width Processing Capability: KINGREAL SLITTING coil slitting machine accommodates metal coils with widths of up to 1650mm, providing the flexibility needed to handle wide-width materials efficiently.

3. High-Speed Production Performance: With a slitting speed of up to 230 meters per minute, KINGREAL SLITTING coil slitting machine significantly enhances production efficiency, meeting the high-output requirements of the customer's factory.

4. Auto Package Unit: In order to maximize the production efficiency of customers, KINGREAL SLITTING coil slitting machine is equipped with a fully automatic package machine. After the metal coils are slit by KINGREAL SLITTING coil slitting line, they will be automatically sent to the package machine for baling. KINGREAL SLITTING coil slitting line can minimize the baling time and save manpower for customers.

This customized solution not only met but exceeded the customer's expectations, offering a comprehensive, high-performance system that seamlessly integrates precision, speed, and versatility.

Performance of KINGREAL SLITTING Coil Slitting Machine

The KINGREAL SLITTING coil slitting machine has delivered transformative benefits to the customer’s operations. By combining compatibility with multiple metal raw materials and exceptional production speed, the machine has eliminated the need for additional equipment, reducing overall production costs. Furthermore, its efficiency and precision have given the customer a distinct competitive edge in the European markets, where high-quality products are paramount.