The light gauge cut to length line is a production equipment that cuts thin metal coils with a thickness of 0.3-3MM according to the customer's preset length. With the rapid development of industrialization, the light gauge cut to length machine has a huge market demand in Indonesia, India, the Philippines, the United States, the United Kingdom and other countries. As an important metal processing equipment, the light gauge cut to length line is widely used in many industries such as automobiles, home appliances, and construction, ensuring the efficient processing and utilization of metal materials in these industries.

The importance of the light gauge cut to length machine lies in its ability to provide efficient and accurate cutting solutions to meet the customized needs of different customers. Through reasonable operation and maintenance, the light gauge cut to length line can significantly improve production efficiency, reduce production costs, and create greater economic benefits for the enterprise. In this article, KINGREAL SLITTING will introduce the operation process and precautions of the light gauge cut to length machine in detail to help you better master the use of this light gauge cut to length line.

1. Working Principle of Light Gauge Cut to Length Line

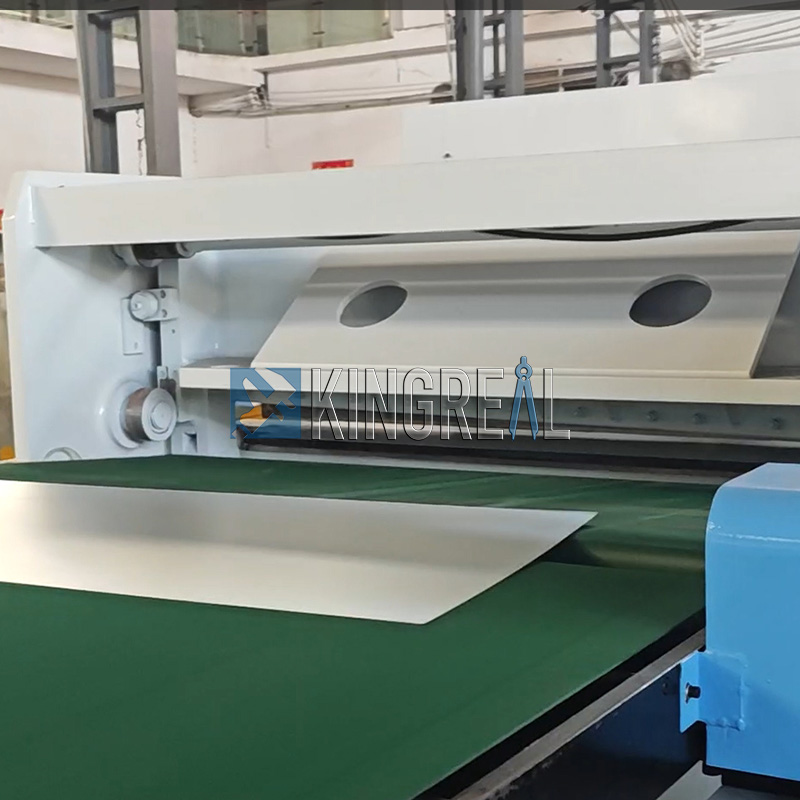

The working principle of light gauge cut to length machine mainly depends on the synergy of various components. After the decoiler unwinds the coil, the leveler ensures its flatness, and then the feeder accurately feeds the material into the shearing machine for shearing. The sheared material is automatically moved to the collection area through the conveying system. The whole process of light gauge cut to length line is monitored and adjusted by the control system to ensure the efficiency and accuracy of production.

2. Preparation Before the Operation of Light Gauge Cut to Length Machine

Before operating the light gauge cut to length line, sufficient preparation is essential.

Equipment inspection

Confirm the power supply and air source connection: Make sure that the power supply and air source of the light gauge cut to length machine are correctly connected to avoid the equipment from not working properly due to power failure or insufficient air pressure. Check the amount of lubricating oil and lubrication status: Check the lubricating oil of the light gauge cut to length line regularly to ensure the smooth operation of all moving parts. Check the wear of the tools and accessories: Confirm whether the tools of the light gauge cut to length machine are worn and replace them if necessary to ensure the shearing quality.

Material preparation

Ensure that the material specifications meet the requirements: Check the specifications of the metal coil before use to ensure that its thickness and width meet the working range of the light gauge cut to length line.

Clean the surface of the material: Remove dirt and debris on the surface of the coil to ensure the accuracy and quality of shearing.

Safety precautions

Wear appropriate personal protective equipment: Operators should wear safety glasses, gloves and protective shoes to ensure their own safety.

Ensure that the operating area is free of debris and obstacles: Keeping the work area clean and tidy will help improve operating safety and reduce the possibility of accidents.

3. Operation Steps of Light Gauge Cut to Length Machine

3.1 Start the equipment

Turn on the power switch: After ensuring that the power supply is normal, turn on the power of the light gauge cut to length line.

Start the control system: Start the PLC control system and perform self-check to ensure that all functions of the light gauge cut to length machine are normal.

3.2 Set parameters

Set the cutting length, quantity and speed on the control panel: Enter the corresponding parameters according to the order requirements.

Confirm the feeding step and number: Ensure that the settings of the feeder are consistent with the cutting requirements.

3.3 Loading materials

Place the metal coil on the decoiler: Ensure that the coil is placed correctly to avoid jamming in subsequent operations.

Adjust the leveler to ensure that the material is flat: The leveler should be properly adjusted before feeding the material to ensure that the material is completely flat.

3.4 Start production

Start the feeder: Start feeding, observe the material feeding, and ensure smoothness.

Monitor material feeding: Ensure that the material does not get stuck during the feeding process and adjust it in time.

3.5 Shearing process

Start the shearing machine for shearing: Shear according to the preset parameters and monitor the shearing process.

Monitor shearing quality: Check the shearing quality regularly to ensure the flatness and size of the cut.

3.6 Collect finished products

Automatically convey the sheared materials: The finished products are automatically conveyed to the collection area through the conveying system.

Ensure that the finished products are neatly stacked: In the collection area, ensure that the finished products are neatly stacked for subsequent processing and transportation.

4. Maintenance and Cleaning after the Operation of Light Gauge Cut to Length Line

4.1 Equipment shutdown

Properly shut down the equipment: After completing production, first shut down the light gauge cut to length machine, and then cut off the power supply.

Perform daily maintenance inspections on the equipment: Check the working status of each component of the light gauge cut to length line and record any abnormal conditions.

4.2 Clean the work area

Clean the work area: clean the work area in time, remove metal chips and debris, and keep the environment clean.

Ensure a clean work environment: a cleaned work area helps improve the safety and efficiency of the next operation.

4.3 Regular maintenance

Develop a regular maintenance plan: develop a corresponding maintenance and servicing plan based on the frequency of use of the light gauge cut to length machine.

Check the lubrication system and tool wear: check the lubrication system regularly to ensure its normal operation and replace worn tools in time.

5. Common Problems and Solutions for Light Gauge Cut to Length Lines

Causes of uneven or uneven shearing

Analyze possible causes: it may be caused by incomplete flattening of the material, tool wear or improper shearing speed.

Provide solutions: ensure that the material passes through the flattening machine, check the tool status, and adjust the shearing speed appropriately.

How to deal with unsmooth feeding

Identify the source of the problem: it may be that the feeder is improperly set or the material is stuck.

Corresponding adjustments and solutions: check the settings of the feeder, ensure that the feeding pitch and number of times meet the requirements, and clean up the stuck material in time.

The light gauge cut to length line is an efficient and precise metal processing equipment, which is widely used in many industries. Through reasonable operation process and maintenance, the light gauge cut to length machine can significantly improve production efficiency and reduce production costs. Understanding the operation steps and precautions of the light gauge cut to length line is essential to ensure the normal operation of the light gauge cut to length machine and the high quality of the finished product. If you have further needs or questions about the light gauge cut to length line, please feel free to contact KINGREAL SLITTING, we will wholeheartedly provide you with professional services and support.