1. Introduction to steel coil packaging line

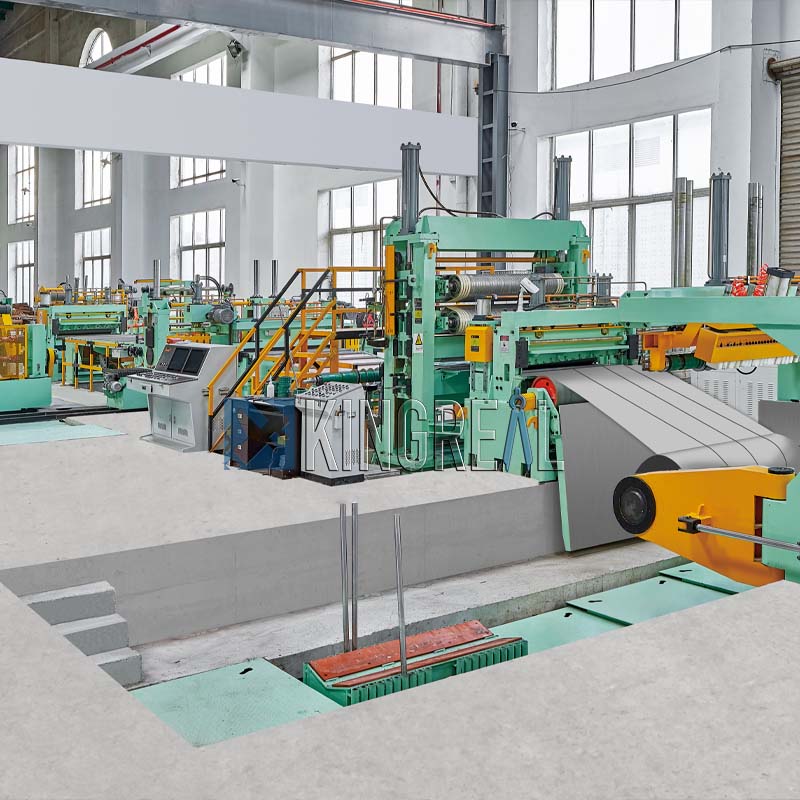

Steel coil packing machine is an important automated equipment in the modern metal processing industry, designed to improve production efficiency and ensure the safety of products during transportation. Steel coil packaging machine is mainly used to fix and bundle the slit steel coils to facilitate subsequent transportation and storage. Usually, steel coil packaging line is used in conjunction with a heavy gauge slitting machine to form an efficient production chain to ensure seamless connection from raw materials to finished products.

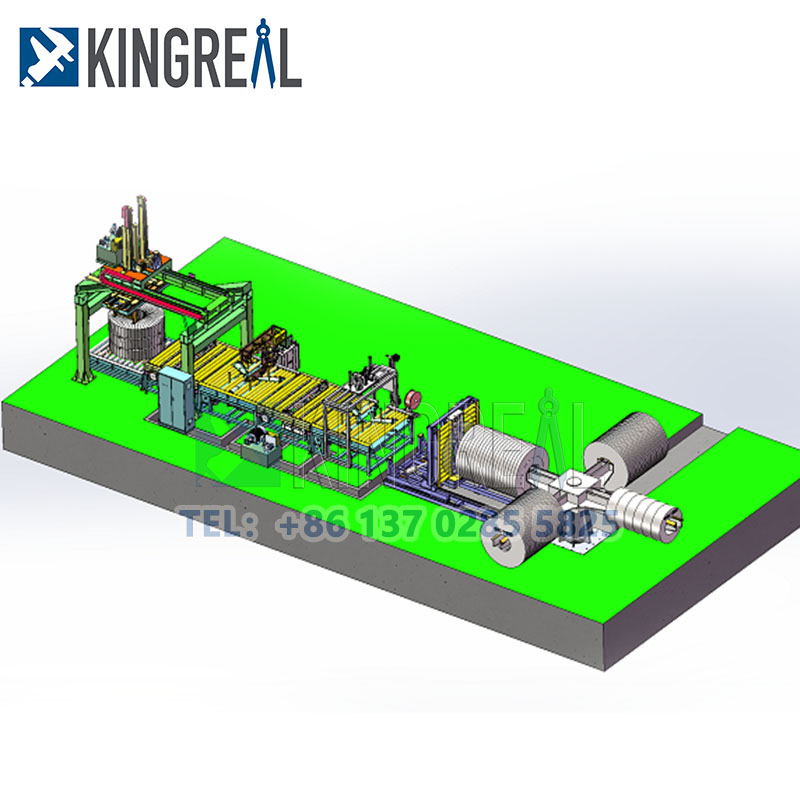

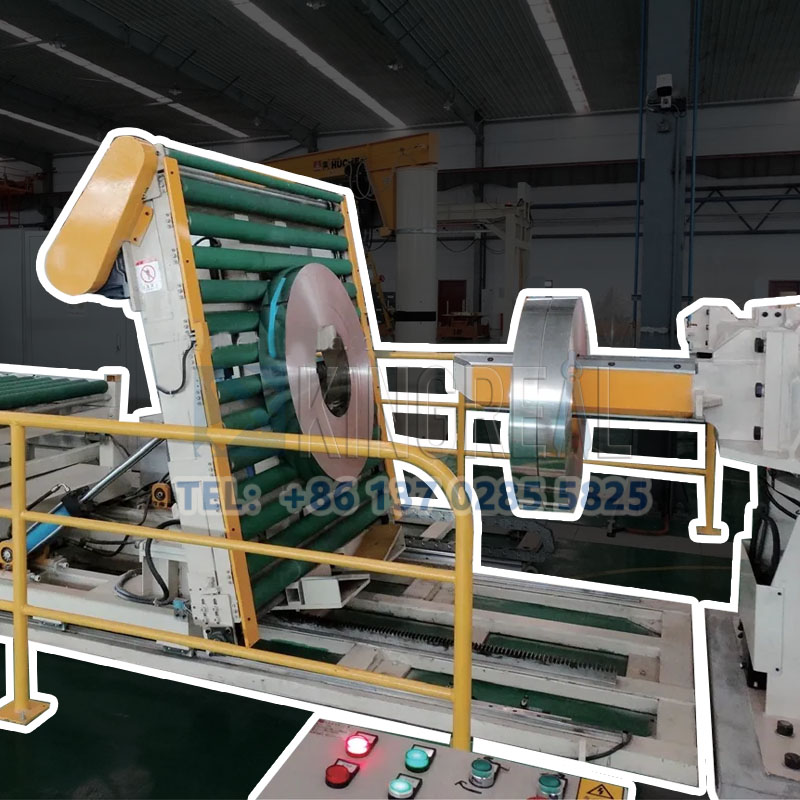

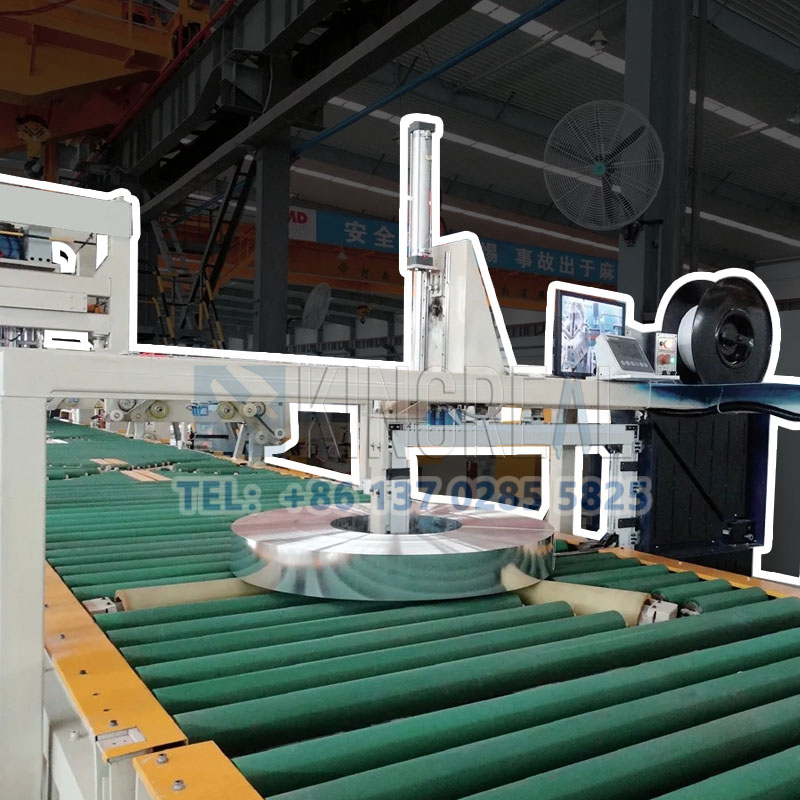

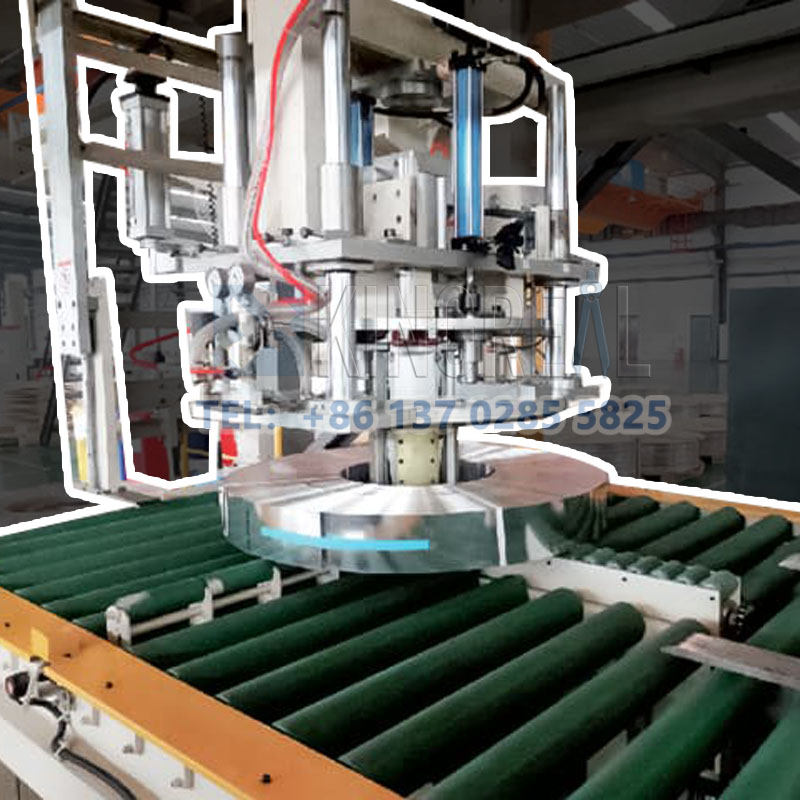

The basic composition of steel coil packing machine includes a variety of equipment such as coil handlers, coil carts, wrappers, strapping units and stacking machinery. These equipment work together to simplify the transition process from slitting to storage. The design of steel coil packaging machine is highly flexible and can be adjusted according to different coil sizes, weights and shapes to ensure that each coil of steel can be perfectly bundled and minimize material waste.

2. Market demand for steel coil packing machine

With the rapid development of global social economy, the market demand for steel coil packaging line is also increasing. Especially in some countries and regions with relatively scarce human resources, high labor costs and large production scales, the application of steel coil packing machine has become more urgent. The following are some representative countries and regions with a large demand for steel coil packaging machines:

(1) India: India's steel industry is growing rapidly, especially in the process of infrastructure construction and industrialization, the demand for automated equipment is increasing. The introduction of steel coil packaging machines helps improve production efficiency and product quality.

(2) The United States: In the United States, although labor costs are high, it also has relatively advanced manufacturing technology. With the increase in requirements for efficient production and environmental protection, the demand for steel coil packaging lines is gradually increasing.

(3) Germany: As an industrial power in Europe, Germany relies heavily on automated equipment in steel production. The application of steel coil packing machines has helped companies reduce operating costs and improve production efficiency.

(4) Brazil: Brazil's steel industry is also continuing to develop, especially in the export market, the demand for efficient and automated production lines is increasing, and steel coil packaging machines have become an important part of it.

3. Advantages of steel coil packaging lines

3.1 Improve production efficiency

One of the biggest advantages of steel coil packing machines is that it significantly improves production efficiency. Through automated strapping, companies can effectively liberate manpower and reduce safety hazards caused by manual operations. In addition, the automated packaging process also greatly shortens the production cycle, allowing products to be put on the market faster.

3.2 Protecting the surface of steel coils

Another important function of steel coil packaging machine is to protect the surface of steel coils. Through bundling, steel coils are not easily scratched or damaged during transportation and handling, thus ensuring the quality of the product. This is especially important for subsequent secondary processing, which can reduce waste and rework caused by surface damage.

3.3 High flexibility

KINGREAL SLITTING's steel coil packaging line is highly flexible and can be compatible with many different types of packaging materials. This allows the steel coil packing machine to meet the needs of different industries and customers. For example, KINGREAL SLITTING's steel coil packaging machine can be used for ordinary steel strapping, plastic strapping, and even advanced protective layers (such as moisture-proof film, pressure-resistant materials, etc.), providing a more comprehensive packaging solution.

4. Collaborative use of steel coil packaging line and heavy gauge slitting machine

The combination of steel coil packing machine and heavy gauge slitting machine is the key to maximizing production efficiency. The heavy gauge slitting machine is responsible for cutting large steel coils into narrow strips required by customers, while the steel coil packaging machine undertakes the task of automatic bundling. Through this collaborative work, enterprises can achieve efficient production processes.

4.1 The role of the heavy gauge slitting machine

The heavy gauge slitting machine is an important equipment at the front end of the steel coil packing machine. It can accurately cut the raw materials according to customer needs. Modern heavy gauge slitting machines are usually equipped with advanced control systems that can achieve high-precision and high-speed operations to ensure that the size and quality of the cut steel bars meet the standards.

4.2 Advantages of automated packaging

After the heavy gauge slitting machine slits the steel, the steel strips will be automatically fed into the steel coil packing machine for packaging. This process is fully automated, reducing manual intervention, which not only improves efficiency but also reduces the risk of operational errors. In addition, the automated steel coil packaging machine can ensure that each roll of steel can be evenly pressed and fixed, further improving the stability and safety of the product.

4.3 Improvement of overall production efficiency

By integrating the steel coil packing machine with the heavy gauge slitting machine, both small and large companies can achieve significant improvements in production efficiency. The overall solution provided by KINGREAL SLITTING ensures the perfect fit between the steel coil packaging machine and the heavy gauge slitting machine, enabling companies to achieve seamless connection during the production process and improve the operating efficiency of the entire production line.

5. Future Development Trends of steel coil packaging line

With the continuous advancement of technology and changes in market demand, the future development trend of steel coil packaging machine is also evolving. Here are some possible trends:

5.1 Intelligent development

In the future, KINGREAL SLITTING's steel coil packing machine will increasingly incorporate intelligent technology. Through big data analysis, the Internet of Things and artificial intelligence, the steel coil packaging machine can monitor the production status in real time, automatically adjust the operating parameters, and improve the level of intelligent production.

5.2 Use of environmentally friendly materials

With the increase in environmental awareness, KINGREAL SLITTING steel coil packaging line will use more environmentally friendly materials for bundling and packaging. This is not only in line with the concept of sustainable development, but also can meet the market demand for green products.

5.3 Customized services

With the diversification of customer needs, the manufacturing of KINGREAL SLITTING steel coil packing machine will pay more attention to providing customized services. By understanding the specific needs of customers, KINGREAL SLITTING can provide personalized solutions to improve customer satisfaction and market competitiveness.