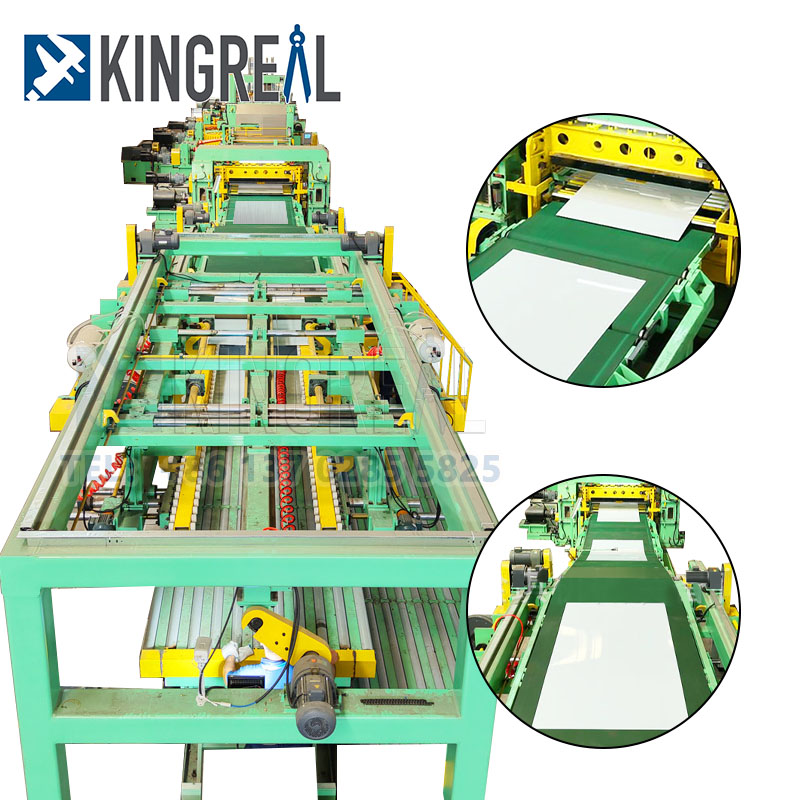

The main function of the rotary shearing cut to length machine is to process the metal coil through automatic hydraulic unwinding, leveling, pit storage buffer, clamping device, NC servo sizing, high-speed rotary shear, conveyor table, double stacking, etc. Since some thin plates such as copper, aluminum, silicon steel, etc. may have imprints when produced by fixed shearing cut to length lines, and the shearing speed is difficult to reach the requirement of a constant speed of more than 60m/min, KINGREAL SLITTING has designed a rotary shearing cut to length line to solve the user's concerns, and more importantly, to achieve applicability and reduce unnecessary waste for users. And KINGREAL SLITTING is an improvement in the speed and accuracy of the applicability of the rotary shearing cut to length machine, providing high-efficiency rotary shearing cut to length lines for material suppliers such as mass production and large hardware accessories users.

In the market, according to different shearing types, it can be divided into flying shearing cut to length lines, swing shearing cut to length lines, rotary shearing cut to length machines, fixed shearing cut to length lines, etc., all of which KINGREAL SLITTING can provide. In this article, KINGREAL SLITTING will give you a detailed introduction to the rotary shearing cut to length machine. If you need more parameter information, please come to consult KINGREAL SLITTING!

How a Rotary Shearing Cut to Length Machine Works?

A rotary shearing cut to length line is a continuous production line. There is no need for a looping pit. The cutting is done by a rotary cutter with a double eccentric structure. Today's double eccentric shears work differently. The upper and lower shear blade beams perform an eccentric motion that is similar to a rotational motion, rather than alternating forward and reverse rotations, making it very smooth. The blades remain in a vertical position throughout the eccentric motion, which helps to minimize burrs. The strip does not need to be accelerated and decelerated for each cut, which reduces the risk of strip slippage. The shear frame itself remains fixed, so wear is reduced, and the shear can be moved quickly within the frame. In a continuous eccentric rotary shearing cut to length line, the bottleneck is not the shearing operation, but the maximum processing speed of the stacker or the capacity of the packaging line. Since the material does not stop for cutting, the average speed of the strip can usually be increased, thereby increasing the total output of the rotary shearing cut to length line. |  |

Main Components of Rotary Shearing Cut to Length Line

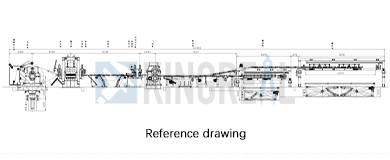

1. Loading trolley 2. Auxiliary support 3. Hydraulic decoiler 4. Six-high leveling machine 5. Side guide 6. Loop 7. Precision NC sizing 8. High-speed precision rotary flying shear host 9. Conveyor belt 10. Stacking rack I 11. Double-layer stacking rack II 12. Lifting and unloading trolley 13. Hydraulic system 14. Pneumatic system 15. Electronic control system |  |

Optional Parameters of Rotary Shearing Cut to Length Line

KINGREAL SLITTING is good at providing personalized manufacturing solutions forrotary shearing cut to length machines based on customer drawings and combined with actual production conditions. The following are some special solutions that KINGREAL SLITTING has provided to customers recently. The specific parameters are for reference only. If you have other needs, please come to consult!

Specifications | Material thickness | Load bearing | Material width | Speed | Shearing accuracy | Leveling accuracy |

| (mm) | (t) | (mm) | (m/min) | (mm) | (mm) | |

| Model 1 | 0.2 - 2.0 | 3、5 | 150 - 650 | 10 - 100 | ±0.15 | 1 |

| Model 2 | 0.2 - 2.0 | 5、10 | 150 - 850 | 10 - 100 | ±0.15 | 1 |

| Model 3 | 0.2 - 2.0 | 10、15 | 300 - 1050 | 10 - 100 | ±0.15 | 1 |

| Model 4 | 0.3 - 2.0 | 10、15 | 300 - 1300 | 10 - 100 | ±0.15 | 1 |

| Model 5 | 0.3 - 2.0 | 15、20 | 300 - 1600 | 10 - 100 | ±0.15 | 1 |

| Model 6 | 0.2 - 3.0 | 3、5 | 150 - 650 | 10 - 100 | ±0.15 | 1 |

| Model 7 | 0.2 - 3.0 | 5、10 | 150 - 850 | 10 - 100 | ±0.15 | 1 |

| Model 8 | 0.2 - 3.0 | 10、15 | 300 - 1050 | 10 - 100 | ±0.15 | 1 |

| Model 9 | 0.3 - 3.0 | 10、15 | 300 - 1300 | 10 - 100 | ±0.15 | 1 |

| Model 10 | 0.3 - 3.0 | 15、20 | 300 - 1600 | 10 - 100 | ±0.15 | 1 |

Advantages of Rotary Shearing Cut to Length Machine:

1. High speed rotary shearing cut to length line, no stamping caused by stopping shearing. The rotary shearing cut to length machine adopts rotary shearing technology, which can shear at high speed. This design minimizes the residence time of the material during the shearing process and avoids the stamping phenomenon caused by stopping shearing. 2. Six-high leveling machine for rotary shearing cut to length line, the leveling accuracy of thin plates is higher. When processing thin plates, flatness is crucial for subsequent processing. The rotary shearing cut to length machine is equipped with a six-high leveling machine, which can perform fine leveling on thin plates. The six-high leveling design makes the pressure on the material more uniform when it is leveled, thereby improving the leveling accuracy. This feature not only effectively eliminates the waves and bends of the material, but also improves the efficiency of subsequent processing steps and reduces the scrap rate. 3. The rotary shearing cut to length line adopts a roller-type lifting pit design, which provides better protection during material transportation. Traditional pits may cause scratches or indentations on the material, while the roller design effectively reduces the risk of damage by reducing the direct contact between the material and the pit. In addition, the lifting mechanism of the roller also improves the efficiency of material transportation, making the material smoother during processing. This meticulous design fully reflects the rotary shearing cut to length machine's care in protecting materials. |  |

4. Double overlapping racks, packaging and bundling without stopping. In the production process, packaging and bundling are usually a time-consuming link. The double overlapping rack design of the rotary shearing cut to length lineenables this link to be completed efficiently. The setting of the double overlapping rack allows packaging on one side while shearing processing can still be performed on the other side, thus achieving non-stop operation. This advantage not only improves production efficiency, but also effectively reduces the downtime of equipment, creating greater output value for the enterprise. 5. The stability and reliability of the rotary shearing cut to length machine are inseparable from a high-quality electronic control system. The rotary shearing cut to length line uses servo electronic control systems, motors and frequency converters from well-known domestic and foreign brands. The excellent performance of these components ensures the smooth operation of the rotary shearing cut to length machine. The servo electronic control system can monitor and adjust the equipment operation status in real time to ensure that the speed and force during the shearing process are always kept at the best state. In addition, the application of the frequency converter makes the motor run more smoothly, reduces energy consumption and prolongs the service life of the rotary shearing cut to length line. |  |