"Stainless steel slitting machines are used to cut metal coils longitudinally and rewind the slit strips into coils. This stainless steel slitting line consists of precision components such as a decoiler, tension station, main coil slitter, and recoiler, etc. Stainless steel slitting machine is suitable for a variety of metal materials, including tinplate, silicon steel, aluminum, copper, stainless steel, and galvanized steel. Stainless steel slitting lines are widely used in the transformer, motor, home appliance, automotive, building materials, and packaging industries."

▎Introduction to Stainless Steel Slitting Machine

KINGREAL SLITTING stainless steel slitting machine unwinds wide metal coils, slits them into narrow strips of precise width, and then rewinds them into individual coils. This line is suitable for a variety of materials, including stainless steel, galvanized steel, carbon steel, aluminum, copper, hot-rolled steel, and cold-rolled steel. The system consists of key components such as a decoiler, slitter, tension station, and recoiler. All components operate fully automatically, ensuring high precision and efficiency. To ensure long-term reliability and stability, KINGREAL SLITTING stainless steel slitting machines are equipped with electrical and control components from internationally renowned brands such as Siemens, Omron, and Schneider. Slitting speeds can be customized to meet production requirements, with standard models ranging from 30 to 180 m/min. The high-speed stainless steel slitting line can reach speeds of up to 230 m/min. KINGREAL SLITTING engineers design stainless steel slitting machines for various material types, production volumes, and specific technical requirements. By thoroughly analyzing customer needs, KINGREAL SLITTING consider dimensions, speeds, blade configuration, and control systems to ensure the precise requirements of each application are met.

▎Workflow of Stainless Steel Slitting Line

Uncoiling → Feeding material into machine →Leveling → Slitting →Tension→Recoiling

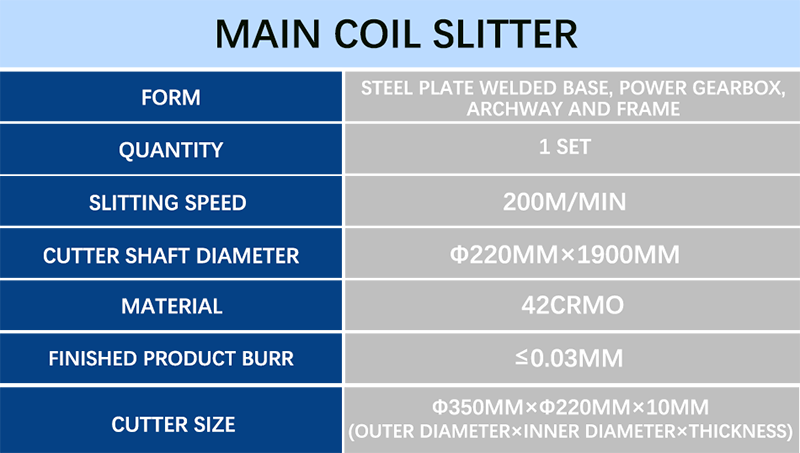

▎Main Technical Parameters of Stainless Steel Slitting Line

▎Process of Metal Slitting Machine

During the slitting stage, the metal strip is prepared for precise slitting to the required dimensions. The unwound coil is loaded into the slitting area, which consists of two parallel mandrels and a precisely machined rotating knife. The circular slitter can cause cracks and breaks when it partially enters the metal coil. The strip is then cut to precise lengths and separated, awaiting downstream operations such as tensioning, rewinding, and stacking. Once the metal coil is precisely cut in the precision stainless steel slitting machine, the outer edges of the strip often exhibit edge trimming or other defects that require additional processing. To handle scrap, today's precision stainless steel slitting lines utilize various accessories, including rubber stripping rings and scrap winders.

Waste collection devices are designed to hold the scrap generated from the precision stainless steel slitting machine under tension. Waste collection devices are particularly useful when installed in pairs, maintaining uniform tension on each scrap strand. Waste collection devices are generally best suited for medium-sized applications with thicknesses up to 0.25 inches. Tensioning devices are also widely used in precision stainless steel slitting lines to handle coils of varying thickness, typically when the main coil has a larger inner diameter and is significantly thinner at the center and edges. This situation results in the center of the material being absorbed more quickly due to the loosely hanging edges. Different types of tensioning frames help effectively handle this issue and ensure product quality.

▎Main Components of Stainless Steel Slitting Machine

1. Decoiler for stainless steel slitting line: Used to unwind the metal coil.

2. Slitter for stainless steel slitting machine: The main component, which cuts the coil.

4. Waste collection device for stainless steel slitting line: Recovers the scrap after slitting.

5. Tension station for stainless steel slitting machine: A servo motor maintains stable tension during the slitting process.

6. Recoiler for stainless steel slitting line: Winds narrow strips for easy transportation and storage.

▎Applications of Stainless Steel Slitting Machine

Stainless steel slitting machines are widely used in various industries, including:

Stainless steel slitting line in transformer and motor manufacturing: Precision cutting of stainless steel and other metal materials to meet the production needs of electrical equipment.

Stainless steel slitting line in home appliance industry: Used for cutting casing materials to enhance product appearance.

Stainless steel slitting machine in automotive manufacturing: Providing precise metal strips for automotive parts, ensuring safety and durability.

Stainless steel slitting machine in construction: Providing metal products required by the construction industry, meeting various specifications.

Stainless steel slitting machine in packaging industry: Used for producing packaging materials, ensuring strength and aesthetics.