As a leading company in the metal slitting machine manufacturing industry, KINGREAL SLITTING has been deeply involved in the market for more than 20 years. Its products are exported to Russia, India, Saudi Arabia, Turkey and other countries, and have won high trust and praise from customers around the world.

In the process of cooperating with customers in many countries, KINGREAL SLITTING has gained wide recognition for its high-quality slitting machines and professional services. In addition to product quality, KINGREAL SLITTING's comprehensive services before, during and after sales have also been well received by customers.KINGREAL SLITTING can not only provide customers with high-performance metal slitting machine, but also ensure that customers can get timely support and solutions throughout the entire procurement and use process through an experienced team of engineers and a 24-hour responsive customer service team.Whether in product selection, machine commissioning, or later equipment maintenance, KINGREAL SLITTING always keeps in close contact with customers to ensure that customer needs are fully met.

Case: 1650mm Coil Slitting Machine

Field Visit:

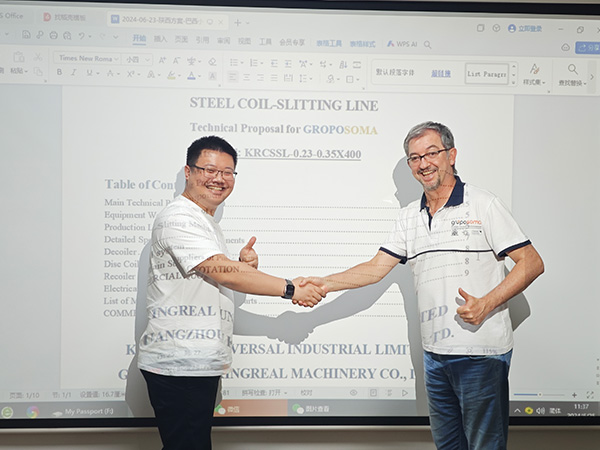

After several online communications with KINGREAL SLITTING staff, Greek customers decided to go to the KINGREAL SLITTING factory in person to inspect the actual operation of the metal slitting machine. In order to ensure that customers can fully understand the performance of the equipment, KINGREAL SLITTING specially arranged reception work. The staff personally picked up the customer to the factory and accompanied the visit throughout the whole process.

During the visit, the professional engineer introduced the various components of the coil slitting equipment in detail, including the decoiler, coil slitter, recoiler, etc., and explained the manufacturing materials, working principles and operation methods of each component. In addition, the customer also personally experienced the operation process of the metal slitting machine and further understood the actual performance of the equipment. Through this series of field visits, the Greek customer has a deeper understanding of the performance of KINGREAL SLITTING's coil slitting equipment and has initially reached a cooperation intention.

Customized solution:

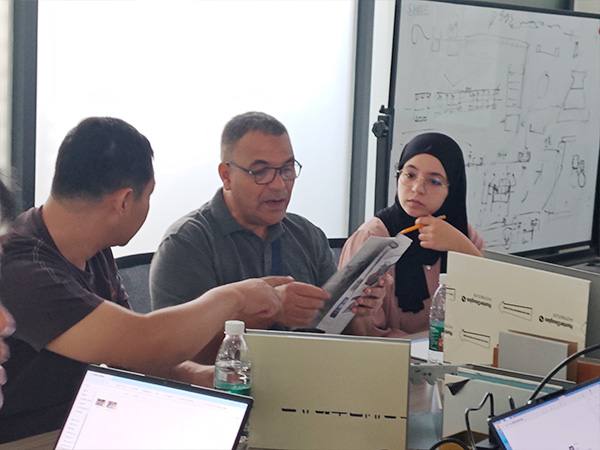

After the initial inspection and factory visit, the Greek customer and KINGREAL SLITTING’s engineers engaged in a more in-depth discussion to thoroughly understand the customer’s specific production needs. This critical phase of communication involved a series of detailed questions from the engineers, which helped them gather comprehensive information about the customer’s operations. The engineers learned about the type of metal materials the customer needed to process, such as steel, aluminum, or copper, and the specific thickness and hardness of these materials. They also discussed the required slitting width, ensuring it aligned with the customer's product specifications.Furthermore, the engineers gathered information about the desired production speed, including the minimum and maximum slitting speeds required for optimal performance.In addition to these core requirements, the engineers also took into account the customer’s existing production processes, equipment limitations, and space constraints within their facility. This allowed the engineers to provide a more holistic solution that would not only meet the immediate slitting needs but also seamlessly integrate into the customer's broader production line. By understanding these factors, the engineers were able to optimize the equipment for both efficiency and flexibility.

Based on the detailed insights provided by the customer, the engineers at KINGREAL SLITTING designed a customized coil slitting equipment solution. This solution was tailored to ensure that the equipment would be capable of handling the customer’s materials with precision, speed, and efficiency. The customized equipment was not only designed to meet the specific slitting width and speed requirements but was also optimized to minimize waste and maximize throughput, improving the overall cost-effectiveness of the customer’s production process.Furthermore, KINGREAL SLITTING’s engineers included advanced features in the solution to ensure ease of operation, maintenance, and future scalability. For example, the solution included a user-friendly interface for monitoring the equipment's performance and real-time adjustments, ensuring that the customer could easily operate the machine with minimal training. The engineers also suggested additional upgrades such as automation and quality control systems, ensuring that the customer would be able to maintain high standards of precision while reducing the need for manual intervention.

Metal slitting machine installation and commissioning:

After the metal slitting machine is manufactured and passes strict trial machine testing, the coil slitting equipment is delivered to the Greek customer's factory. In order to ensure that the equipment is put into production smoothly, KINGREAL SLITTING dispatched experienced engineers to the customer site for installation, commissioning and operation training.The engineers first carried out a detailed inspection of the equipment to ensure that the equipment was not damaged during transportation. Then, they started the on-site installation of the metal slitting machine and debugged it to ensure that the various indicators of the equipment met the needs of the customer. During the test, KINGREAL SLITTING engineers debugged the equipment with the workers to ensure that the running speed and accuracy of the metal slitting machine reached the best state.

After the equipment was successfully debugged, the engineers also conducted operation training for the workers, explaining in detail the startup, adjustment, and daily maintenance of the equipment. In addition, the engineers also envisioned the problems that the workers might encounter during the operation in advance and provided them with relevant solutions. Only after the workers were able to operate the equipment independently and ensure its smooth operation, did the KINGREAL SLITTING engineers end the service.

KINGREAL SLITTING service accompanies customers throughout the process to ensure that customers are worry-free

KINGREAL SLITTING's service is not limited to the installation and commissioning of the equipment, but more to the full-time accompaniment and support of customers during the use of the equipment. Whether it is equipment maintenance, troubleshooting, or optimization of production processes, KINGREAL SLITTING can provide customers with timely and effective help.From pre-sales to after-sales, KINGREAL SLITTING always pays attention to changes in customer needs to ensure that eachmetal slitting machine can perform at its maximum efficiency on the customer's production line.