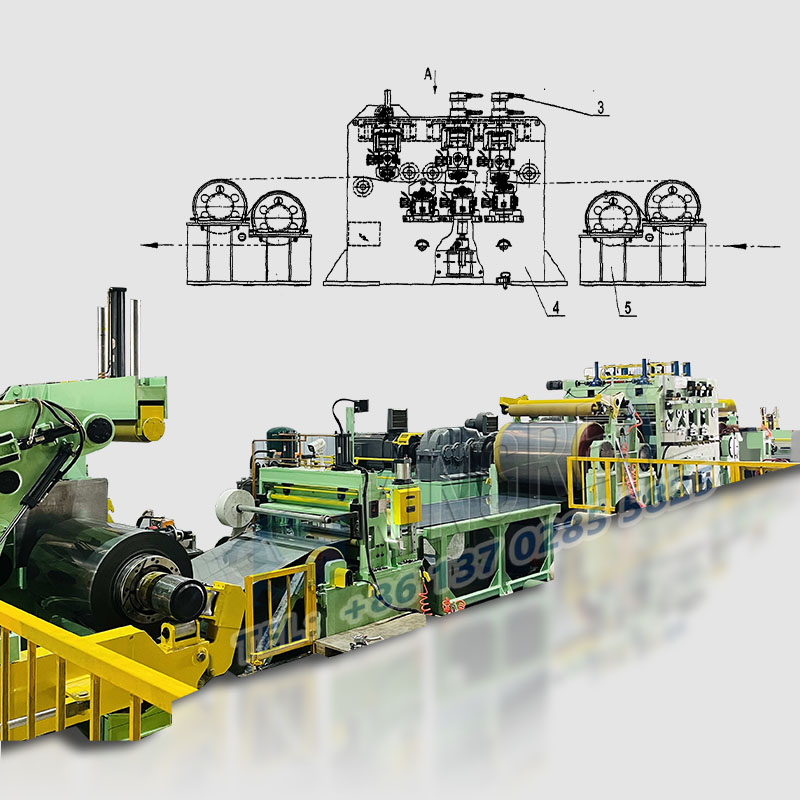

What is a Stretch Levelling Lines?

Stretch levelling lines is a type of processing equipment specifically for metal strip. Its primary function is to stretch and deform the metal strip using a series of precision components to eliminate or reduce unevenness Stretcher leveler’s operating principle involves the coordinated operation of multiple components, including a decoiler, a pinch mechanism, a crop shear, an inlet tension roller assembly, a straightening unit, and an outlet tension roller assembly.

Through this combination of components, stretch levelling lines effectively eliminate surface defects such as wavy edges, undulations, camber, and slight camber on metal sheets, significantly improving the flatness of thin sheets. KINGREAL SLITTING Stretcher levelers can process a variety of raw metals, including hot-rolled and cold-rolled materials, stainless steel, aluminum, and copper. They can process metal coils with thicknesses ranging from 0.1 to 2.0 mm and widths ranging from 800 to 2000 mm.

And stretch levelling lines achieve speeds of up to 400 m/min and an elongation accuracy of ±0.01%. This makes the stretcher leveler ideal for ensuring metal materials remain flat and stable during cutting, forming, or welding, providing customers with exceptionally flat materials, improving production efficiency, reducing scrap, and optimizing production processes.

Working Principle of Stretch Levelling Lines

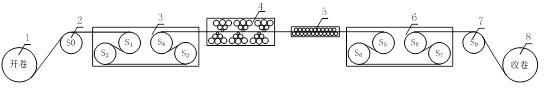

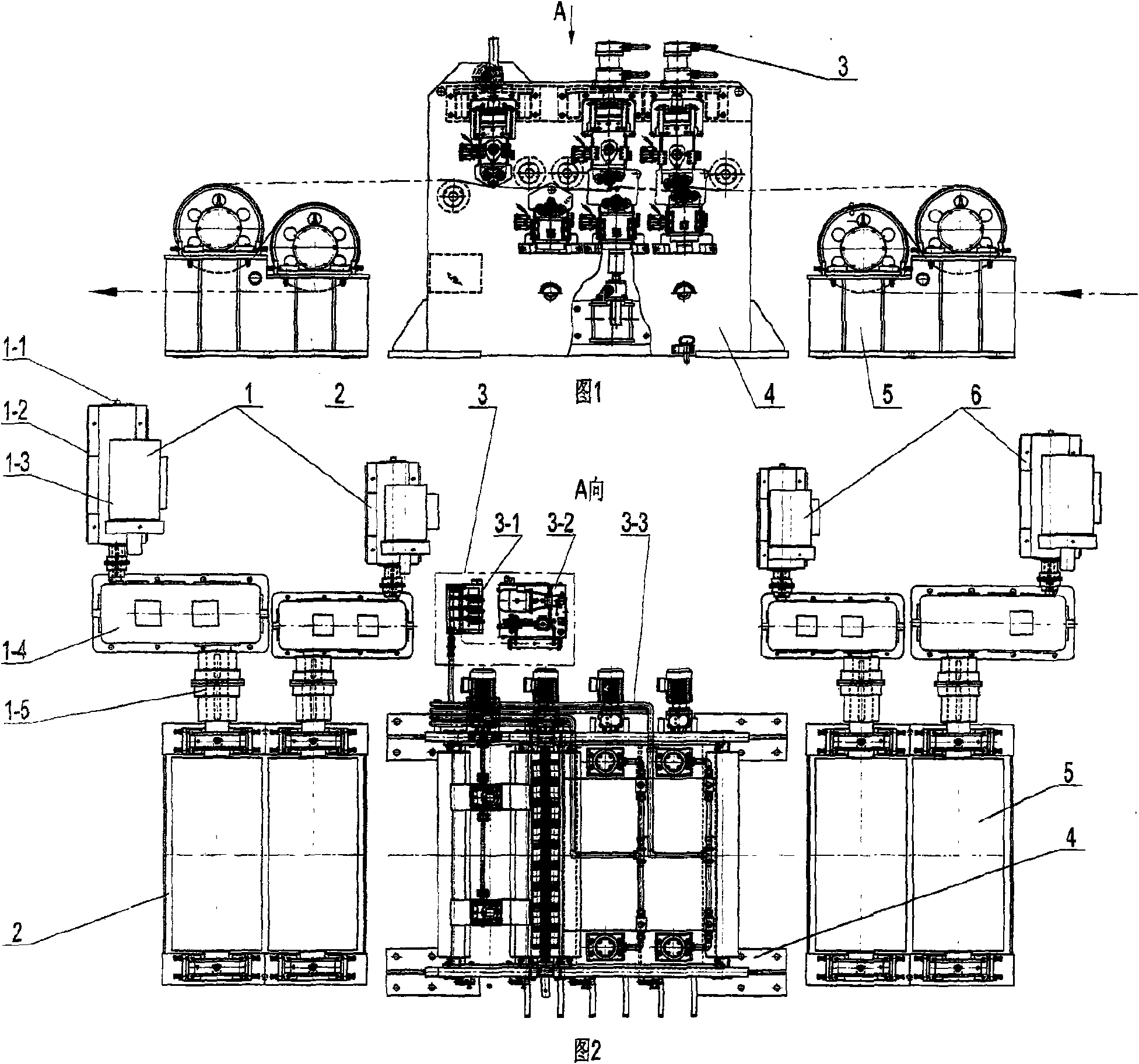

The core of a stretcher leveler lies in its ability to straighten metal coils to achieve the desired shape and size. During the straightening process, stretch levelling lines typically utilize a two-roller or four-roller straightening mechanism. Two-roller straightening mechanisms achieve straightening through the rolling motion of two rollers, while four-roller straightening mechanisms apply uniform pressure in four directions, ensuring a more balanced straightening of the coil.

·Deformation and Internal Stress in Strip Material

During cold working, strip material is prone to defects such as corrugation, warping, side camber, and buckling due to factors such as the roll profile and roll gap. These problems are often caused by uneven longitudinal extension of the coiled strip across its width, which leads to the formation of internal stresses. Therefore, effective straightening of the coiled strip is essential to eliminate these defects. The stretcher leveler combines the advantages of a continuous tension leveler and a parallel roller leveler. Through the combined action of stretching and continuous alternating bending, it produces plastic elongation, achieving excellent straightening results.

Stretch levelling lines equipped with two tension roller sets at the inlet and outlet of the roller leveler, which apply tension to the strip. During the straightening process, the strip undergoes multiple stages of deformation and correction, effectively eliminating various three-dimensional flatness defects.

Parameters of Stretcher Leveler

KINGREAL SLITTING provides customized stretch levelling lines manufacturing solutions based on the customer's specific production needs. The following are some standard model parameters for reference:

Model | Material Thickness | Material Width | Work Roll Diameter |

| Model 1 | 0.2-1.0 | ≤300 | Φ40 |

| Model 2 | 2 0.2-1.0 | ≤550 | Φ40 |

Model 3 | 0.2-1.2 | ≤700 | Φ40 |

Model 4 | 0.2-1.5 | ≤900 | Φ25 |

Model 5 | 0.3-1.5 | ≤1000 | Φ25 |

| Model 6 | 0.3-1.5 | ≤1250 | Φ25 |

Model 7 | 0.3-2.0 | ≤1400 | Φ25 |

For special production requirements, please feel free to contact KINGREAL SLITTING.

Main Components of Stretcher Leveler

Stretch levelling lines consist of a decoiler, a pinch device, a crop shear, an inlet tension roller assembly, a straightening unit, an outlet tension roller assembly, an outlet guide roller assembly, a winder, and other precision components. Among them, KINGREAL SLITTING can equip the stretcher leveler with a feeding trolley and a discharging trolley to meet the fully automated machine operation process.

Technical Explanation of Stretch Levelling Lines

(1) Tension control of stretcher leveler

Tension control is a crucial link in the operation of the straightening machine. By accurately controlling the stress state of the metal coil, the straightening machine can achieve the expected processing effect. Generally speaking, the straightening machine adopts hydraulic tension control technology, and a small number of vehicle-mounted straightening machines adopt electric tension control technology. In the hydraulic control mode, the hydraulic control system provides stable stretching and straightening force to ensure good coil forming effect. The advantage of the hydraulic system is that it can adapt to coils of different materials and thicknesses, and has higher processing flexibility.

(2) Driving mode of the stretch levelling lines

The straightening machine usually adopts two modes: electric drive and hydraulic drive. The electric drive mode relies on the motor to drive the coil for stretching and straightening. Its control is relatively simple and suitable for the processing of small and light coils. The hydraulic drive mode is driven by the hydraulic control system to provide driving force. It is suitable for the processing of large and heavy coils, but its control system is relatively complex and the cost is relatively high.

Features of Stretcher Leveler

(1)Metal clamps for stretch levelling lines

The metal clamps on the stretcher leveler feature an advanced non-slip design, ensuring zero damage to the material during the clamping process. This design not only effectively prevents slippage between the clamp and the material, but also maintains a stable clamping position even under high loads. The non-marking feature means that no clamping marks remain on the material surface after processing.

(2)Adjustable clamping pressure

The clamping pressure of the stretch levelling lines can be flexibly adjusted to suit the characteristics and thickness of the material. This adjustability allows the stretcher leveler to adapt to various process requirements, ensuring the appropriate clamping force during processing, whether working with thick metal sheets or thinner materials. Furthermore, the operator can quickly adjust the clamping pressure based on actual production conditions.

(3)Balanced stress relief and springback

Through precise tension control and balanced stress distribution, the stretch levelling lines effectively eliminates internal stress generated during processing, preventing springback after processing. This feature not only improves material flatness but also ensures dimensional stability in the final product.

(4)Achieving 0 to 1 unit flatness

The high-precision design of the stretcher leveler enables it to typically achieve 0 to 1 unit flatness, meeting customers' stringent product quality requirements. This flatness is particularly important for subsequent processes such as cutting, forming, or welding, ensuring consistent and stable material quality.

(5)Reducing scrap for stretch levelling lines

By optimizing the production process, the stretcher leveler significantly reduces scrap. Efficient operation and precise control during processing maximize material utilization and reduce the production of defective products.

(6)Processing without altering the material's mechanical properties

The advanced technology used in the stretch levelling lines ensures that the material's mechanical properties are not affected. Whether stretching or straightening, the material's strength and toughness remain at their original levels.

This feature ensures that customers who choose the stretcher leveler can obtain high-quality finished products without worrying about material degradation.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil