Video About Steel Cut to Length Line

Description of Steel Cut to Length Line

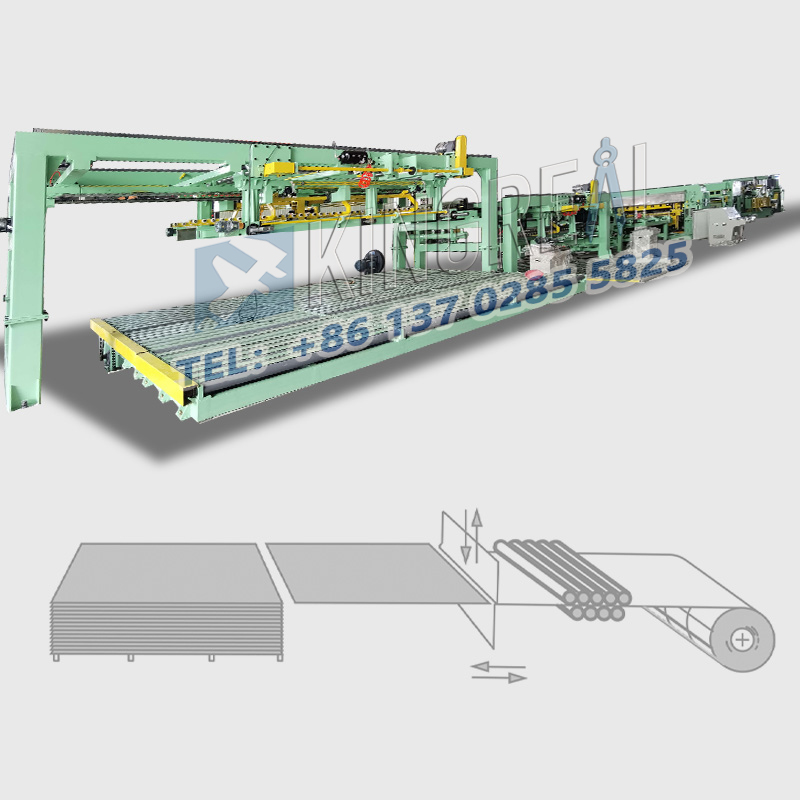

Steel cut to length lines are designed to efficiently process a variety of steel, non-ferrous metals, or aluminum materials, precisely cutting coils into uniform lengths. KINGREAL SLITTING steel cut to length machine excel at this process, efficiently handling both narrow coils and wide coils up to 2000 mm. KINGREAL SLITTING steel cut to length lines integrate key components such as decoiler, straightener, servo feed roller, and cut-to-length-machine, all of which are independently developed and manufactured by KINGREAL SLITTING, ensuring the efficiency and reliability of the entire steel cut to length line.

KINGREAL SLITTING steel cut to length machines can cut hot-rolled, cold-rolled, and galvanized steel to desired lengths in a wide range of specifications and lengths. Whether processing thin or thick coils, KINGREAL SLITTING steel cut to length lines offer the flexibility to handle a wide range of cutting sizes, fully customized to meet specific customer application requirements. KINGREAL SLITTING also offers efficient steel cut to length machine manufacturing solutions, including designs utilizing fly shearing system (with servo positioning axes) or with ring pits and high-speed servo feed rollers to meet diverse production requirements.

Technical Specifications of Steel Cut to Length Line

Coil Weight: Up to 30,000 kg (66,140 lb)

Belt Width: Up to 2,600 mm (102 in)

Material Thickness: 0.1 to 6.0 mm (0.04 to 0.24 in)

Cutting Speed: Over 120 m/min (394 ft/min)

Customized Steel Cut to Length Machine Manufacturing Solutions

1. Professionally designed and customized steel cut to length line

KINGREAL SLITTING steel cut to length machines are designed to meet the specific needs of our customers. KINGREAL SLITTING offers steel cut to length lines that process standard coil sizes as well as custom designs tailored to the requirements of specific industries or applications. KINGREAL SLITTING team of engineers works closely with customers to gain a deep understanding of their production processes, material properties, and end-product specifications to design the most suitable steel cut to length machine.

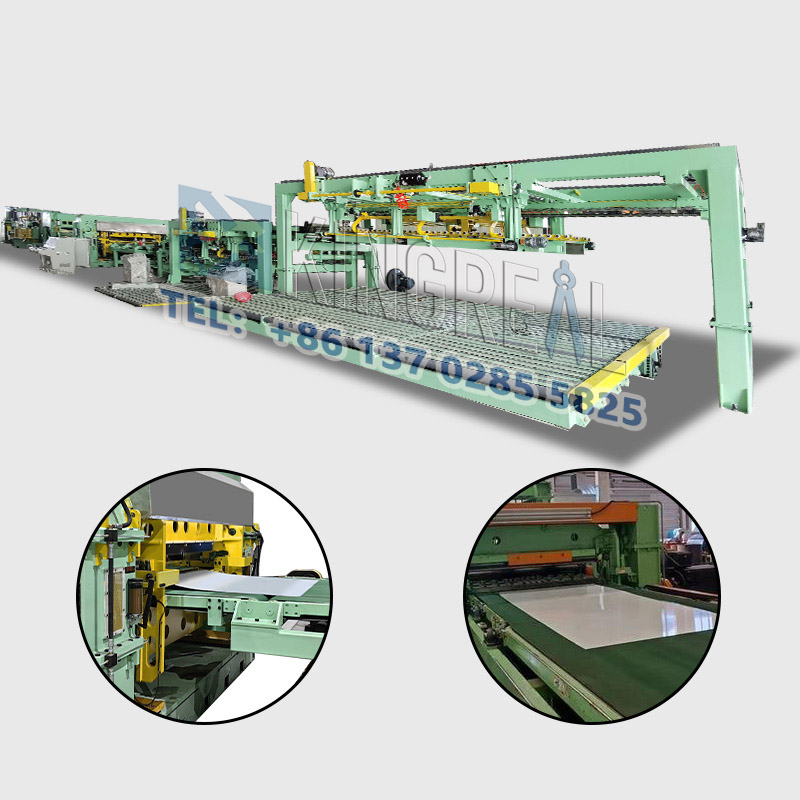

For example, for materials such as stainless steel and aluminum, which require high aesthetics in the automotive industry, KINGREAL SLITTING steel cut to length lines feature high-precision levelers. This 6HI leveling machine not only ensures sheet flatness during processing but can also be equipped with interchangeable leveling cassettes and roller cleaning devices upon request to enhance surface quality and ensure the final product's appearance meets customer specifications.

2. High-speed steel cut to length machine

KINGREAL SLITTING steel cut to length lines are capable of continuous production speeds of up to 120 m/min. KINGREAL SLITTING stacking system is designed specifically for such high flow rates. Featuring dual stations and a non-stop operation, it enables efficient material changeover during production, minimizing downtime and improving overall production efficiency.

In addition, KINGREAL SLITTING high-speed servo feed roller system ensures a consistent material feed rate during processing, reducing cutting errors caused by uneven feeding.

3. Diverse stacking systems for steel cut to length machine

KINGREAL SLITTING provides a range of stacking systems—including magnetic, vacuum, and mechanical stacking systems with air cushions—to satisfy different customer needs. These stacking systems guarantee the safety and stability of materials during manufacturing, therefore avoiding damage or deformation brought on by incorrect stacking.

4. Integrated trimming shears and scrap handling systems

KINGREAL SLITTING steel cut to length lines integrate trimming shears with scrap handling systems (such as scrap coilers or scrap cutters) to effectively handle scrap generated during the cutting process. This not only improves production efficiency but also reduces scrap disposal costs.

5. Capability to process ultra-high-strength materials

With experience in handling ultra-high-strength materials, KINGREAL SLITTING steel cut to length machines can process steels with tensile strengths exceeding 1,500 N/mm² (0.22 psi) and yield strengths over 1,100 N/mm² (0.16 psi). This capacity lets KINGREAL SLITTING steel cut to length machines meet the very exacting material performance demands of sectors including construction, aerospace, and auto manufacturing.

The qualities of these high-strength materials are considered by the KINGREAL SLITTING engineering team when designing their steel cut to length lines to guarantee the structure of the equipment. And arrangement can resist the high-load cutting processes, therefore guaranteeing stability and longevity.

Features of Steel Cut to Length Machine

1. High-speed steel cut to length line

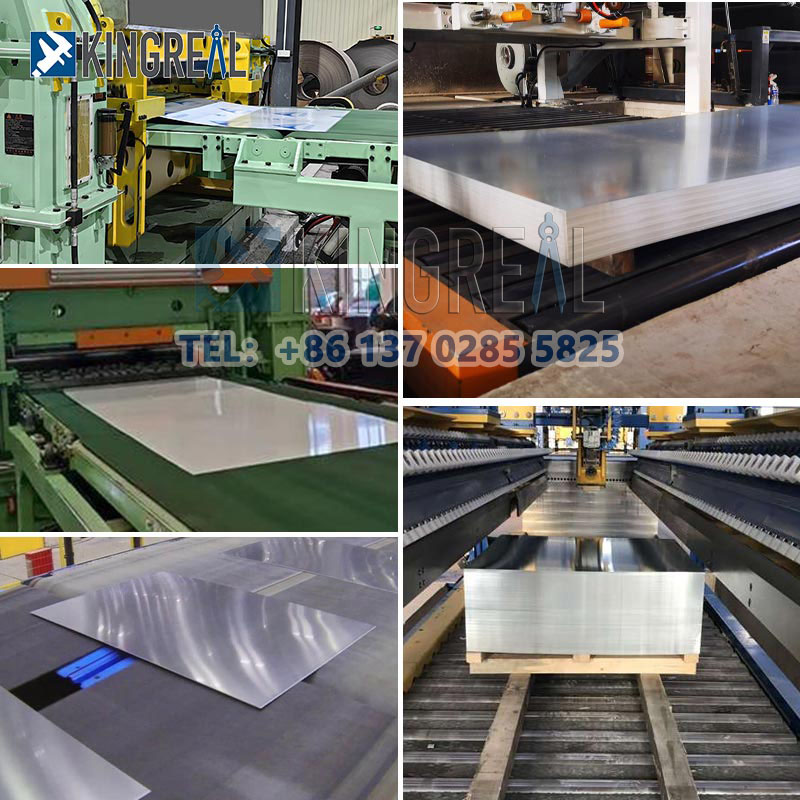

KINGREAL SLITTING steel cut to length machines offer the advantages of high-speed, precision cutting. KINGREAL SLITTING cutting system utilizes advanced servo motors and precision control technology to ensure high cutting accuracy while operating at high speeds. Each cut length can be adjusted to customer needs without compromising tolerances, ensuring precision and consistency in the final product.

2. Multiple cutting capabilities before tool regrinding

KINGREAL SLITTING steel cut to length line design allows for multiple cuts before tool regrinding, extending tool life and reducing long-term operating costs. Depending on material properties, tool life can reach up to 10 million cuts, significantly reducing the frequency of tool changes and associated maintenance costs.

3. High-quality steel cut to length machine

During the cutting process on the steel cut to length line, burr height is minimized, and width tolerances are also tight, ensuring perfect plate rectangularity. The finished plate length tolerance on KINGREAL SLITTING steel cut to length machine can reach ±0.125 mm, significantly improving product quality and market competitiveness.

4. Easy-to-maintain and operate steel cut to length line

KINGREAL SLITTING steel cut to length machines are designed with the operator experience in mind. For even inexperienced operators to quickly grasp the process, KINGREAL SLITTING steel cut to length line has a user-friendly interface and straightforward operation. Moreover built for simple user maintenance, the steel cut to length machine enables frequent cleaning, inspection, and component replacement, so reducing downtime.

To make sure steel cut to length lines are always in perfect form, KINGREAL SLITTING advises clients to create a thorough maintenance schedule. Regular upkeep guarantees steady and effective production in addition to increasing the life of the steel cut to length machine.

Factors to Consider When Selecting a Steel Cut to Length Line

1. Material compatibility for steel cut to length line

Choosing a steel cut to length machine demands assurance that it can manage the requested metal types and thicknesses. To satisfy the demands of a variety of consumers, KINGREAL SLITTING steel cut to length line works on a large spectrum of materials.

2. Production speed for steel cut to length line

Choosing a steel cut to length machine that meets your production needs is crucial. KINGREAL SLITTING steel cut to length machines offer continuous production speeds of up to 120 m/min, ensuring they meet the demands of large-scale production.

3. Plate length accuracy for steel cut to length line

Confirming that the steel cut to length machine can achieve the required length accuracy is also a key consideration when selecting a steel cut to length line. KINGREAL SLITTING steel cut to length machines excel in this area, offering length tolerances up to ±0.125mm.

4. Easy maintenance for steel cut to length line

Selecting a steel cut to length line with low maintenance requirements to minimize downtime is an effective way to improve production efficiency. KINGREAL SLITTING designs its steel cut to length lines to be both easy to operate and maintain, ensuring continued efficient operation of the line.

FAQs About Steel Cut to Length Machine

What materials can a steel cut to length line process?

KINGREAL SLITTING steel cut to length machines can handle a wide range of materials, including steel, aluminum, stainless steel, and other metals of varying thicknesses, ensuring they meet diverse market demands.

What is the difference between a steel cut to length line and a metal coil slitting line?

While both process metal coils, a steel cut to length machine cuts the coil horizontally to produce sheets, while a metal coil slitting line cuts the coil longitudinally to produce narrower strips.

Can a steel cut to length machine handle custom length requirements?

Yes, KINGREAL SLITTING steel cut to length machines can be designed to meet specific customer requirements, cutting panels into custom lengths to ensure they perfectly meet your production needs.

What maintenance is required for a steel cut to length machine?

Regular cleaning, inspections, and occasional parts replacement help maintain the efficiency and lifespan of your steel cut to length line. KINGREAL SLITTING recommend that you develop a detailed maintenance plan to ensure your steel cut to length machine is always in optimal condition.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil