Definition of Levelling And Cut To Length Line

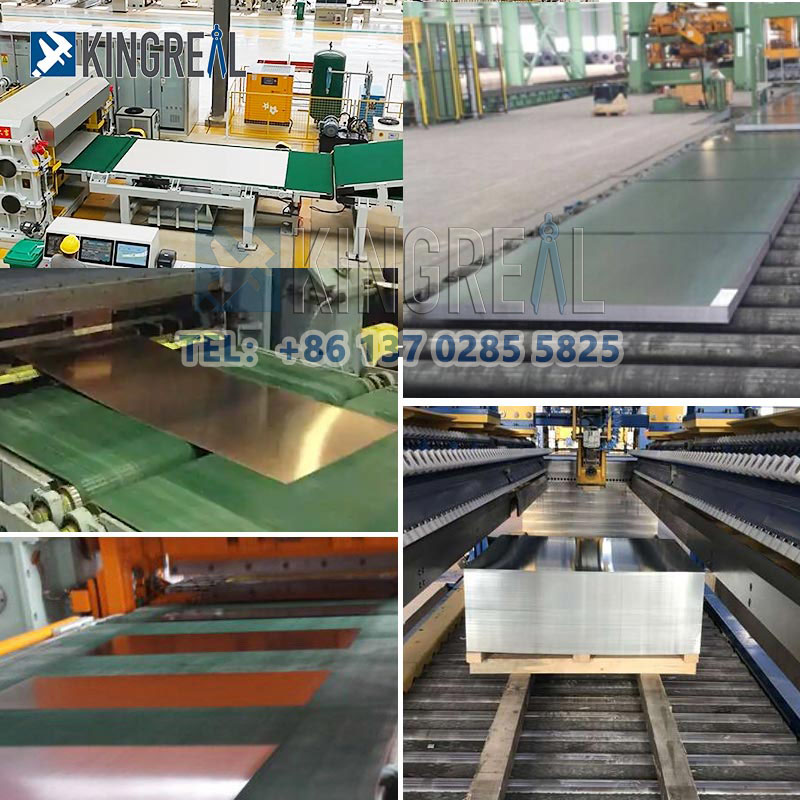

KINGREAL SLITTING levelling and cut to length lines are specifically designed for leveling and cutting high-strength materials such as cold-rolled, hot-rolled, galvanized steel coils, pre-coated steel coils, stainless steel, and aluminum. KINGREAL SLITTING latest levelling and cut to length machine can handle coils up to 2200 mm wide, 25 mm thick, and with a strength of up to 2000 N/mm², achieving perfect leveling quality and precise cutting.

This levelling and cut to length line utilizes a precision leveler with a six-roller structure. By adjusting the leveler's operating parameters, tension leveling can be achieved. The leveled sheet surface has minimal flatness error, with no scratches or indentations, meeting the stringent surface precision requirements of high-end manufacturing industries and providing customers with high-quality sheet materials.

Workflow of Levelling And Cut To Length Line

Loading - Uncoiling - Pressing and Guiding - Pinch-feeding - Transitional Worktable - Guiding - Leveling - Length Measuring - Cross Shearing - Unloading-Stacking

Technical Specifications of Levelling And Cut To Length Line

Thin Sheet Material | Medium Sheet Material | Thick Sheet Material | |

Roll Weight | 10 to 30 tons | 15 to 36 tons | 15 to 42 tons |

| Thickness | 0.2 to 4 mm | 1.5 to 12 mm | 3 to 25.4 mm |

| Width | 200 to 2200 mm | 500 to 2200 mm | 500 to 2200 mm |

Speed | 40 to 120 m/min | 40 to 80 m/min | 20 to 40 m/min |

Advantages of Levelling And Cut To Length Line

1. Excellent leveling effect for levelling and cut to length line

When designing the levelling and cut to length line, KINGREAL SLITTING engineers customize the parameters and performance of the leveling machine according to the customer's actual project needs. This levelling and cut to length machine is equipped with state-of-the-art tension leveling system technology, combined with different types of precision leveling machines (4-layer and 6-layer) and leveling rollers of different sizes to ensure high-quality leveling results. All leveling machines are highly precise and durable, effectively reducing material internal stress and ensuring the flatness of the final sheet.

Notably, KINGREAL SLITTING levelling and cut to length line can be equipped with up to two leveling machines. Through two leveling processes, sheets with low internal stress and extremely high flatness can be produced. KINGREAL SLITTING levelling and cut to length machines achieve a straightening accuracy of 1.2mm/㎡-1.5mm/㎡, providing customers with high value-added products.

2. High compatibility for levelling and cut to length machine

KINGREAL SLITTING levelling and cut to length line has excellent compatibility, capable of handling various metal materials such as stainless steel, steel, hot-rolled, cold-rolled, copper, and aluminum. This high compatibility ensures a high plastic deformation rate of materials during processing, thereby adding value to the customer's final product and making this levelling and cut to length machine suitable for the needs of various industries.

3. Precision cutting for levelling and cut to length machine

KINGREAL SLITTING levelling and cut to length line is equipped with a CNC closed-loop length-fixing system, ensuring high cutting accuracy. Combined with servo motor drive, it achieves both high precision and improved production efficiency. This system can cut sheets of a predetermined length measured by the cut-to-length machine, driven by a powerful hydraulic cylinder for rapid cutting. The shear gap can be adjusted via a human-machine interface. Furthermore, the four-sided shears can be interchanged and used alternately, and the bottom-up cutting design effectively protects the integrity of the sheet surface, avoiding scratches and damage.

4. Various shearing systems for levelling and cut to length line

To meet different customer production needs, KINGREAL SLITTING levelling and cut to length machine can be equipped with four different shearing systems: rotary shearing, fly shearing, swing shearing, or fixed shearing. Based on the customer's project requirements, a suitable shearing method can be selected, making the levelling and cut to length line's application more flexible and efficient.

Levelling And Cut To Length Line Solution

This levelling and cut to length machine is designed for customers with high requirements for shearing accuracy and sheet flatness. The key feature of this levelling and cut to length machine is its significantly higher capacity than any common cut to length machine, thanks to its integrated rapid feeding system, automatic threading device, flying shear unit, and dual-station stacker crane. The entire levelling and cut to length line maximizes production efficiency, achieving automation and helping customers increase output while ensuring sheet quality.

1. Production automation for levelling and cut to length line

Through automated design, the levelling and cut to length machine achieves high-efficiency production with minimal labor costs. The combination of automatic threading and rapid feeding systems allows the entire production line to complete operations quickly and accurately, further improving overall production efficiency.

2. User-friendly interface for levelling and cut to length line

KINGREAL SLITTING levelling and cut to length machine is equipped with user-friendly controls and software that can handle most tasks and logically guide operators through the setup process. This allows even novice operators to quickly get started, reducing training costs and improving work efficiency.

3. On-site training service for levelling and cut to length line

To ensure smooth operation of the customer's levelling and cut to length machine, the KINGREAL SLITTING team provides on-site training services. KINGREAL SLITTING professional engineers will travel to customer factories to provide levelling and cut to length line operation training, ensuring employees receive adequate training to successfully operate the levelling and cut to length machine and maximize its efficiency.

Need More Information?

1. How complex is operating a levelling and cut to length line?

Not at all. KINGREAL SLITTING levelling and cut to length machines are equipped with a user-friendly control system that is easy to operate, handles most tasks, and logically guides operators through setup. Even employees with no operating experience can quickly master it.

2. Why choose KINGREAL SLITTING levelling and cut to length line?

KINGREAL SLITTING is your trusted coil processing equipment supplier, offering a wide range of high-quality levelling and cut to length machines to meet diverse manufacturing needs. With expertise in fly shearing cut to length lines, rotary shearing cut to length lines, fixed shearing cut to length lines, and heavy duty cut to length lines, KINGREAL SLITTING helps customers find cost-effective levelling and cut to length machine solutions to improve production efficiency.

3. How to choose a levelling and cut to length line?

Choosing the right levelling and cut to length line requires evaluating multiple factors to ensure it meets production needs. These factors include material type and thickness, level of automation, and stacking method. By comprehensively considering these factors, you can select the levelling and cut to length machine best suited to your production needs.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil