Video About Blanking Line Cut To Length

Professional Blanking Line Cut To Length Machine Manufacturing

Blanking Line Cut To Length, also called cut to length line manufacturing buy KINGREAL SLITTING, design to cutting different material coil to the sheet. Whether it's large coils (up to 20mm thick) or small coils (down to 0.3mm thick), KINGREAL SLITTING Blanking Line offers a perfectly matched solution. the Cut to length line allows customers to cut the specified width of plate, controlling the quality and efficiency of the production, and helping customers to stay ahead of the curve in the industry. The Cut to length line allows the customer to control the quality and efficiency of the production, helping the customer to gain a better market position and reputation in the industry.

KINGREAL SLITTING expertise in the manufacturing of cut-to-length lines is not only to realize the cutting of customer-specified widths of plates, but also requires continuous research, development and innovation in terms of the straightness of the coils, the surface treatment process, the speed of the production, and the full automation of the entire line. By choosing KINGREAL SLITTING Blanking Line solution, we can help our customers to gain an effective position in the industry and sustainable development. KINGREAL SLITTING offers its customers optimal solutions from the design of the cut-to-length line machine drawing, to the manufacture of the components, to the assembly and testing of the entire line, to the installation and operation of the machine after shipment.

Maybe you are in the early stage of blanking line industry or exploring the stage, it doesn't matter! KINGREAL SLITTING provides you with professional technical solutions, the next is the introduction of our cut to length line equipment.

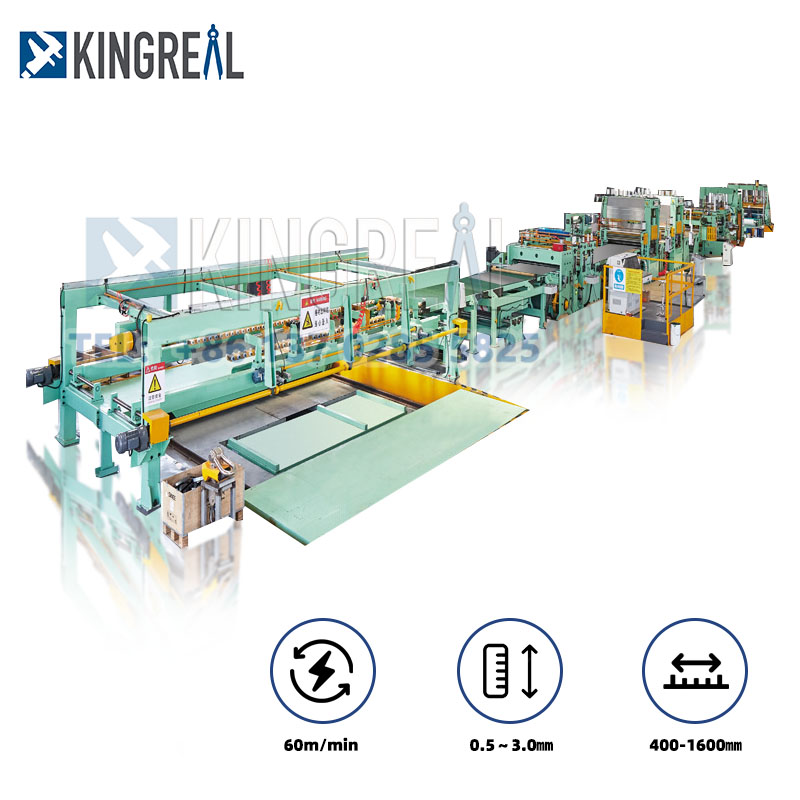

Multi Blanking Line Standard Working Parameters

Cutting speed: 60m/min(adjustable)

Threading speed: 0~15m/min

Power supply: 416V/50Hz/3ph

Total Power: ~220KW

Sheet thickness: 0.5~3.0㎜

Sheet width: 400~1600㎜

Maximum coil weight: 20T

Component List Of Blanking Line With Cut To Length

No. | Name | Quality |

| 1 | Material preparation table | 1 set |

| 2 | Loading trolley | 1 unit |

| 3 | Hydraulic manipulator | 1 unit |

| 4 | Hydraulic uncoiler | 1 set |

| 5 | Six HI leveling machine | 1 set |

| 6 | Laminating device | 1 unit |

| 7 | Loop bridge | 1 unit |

| 8 | Servo shearing machine | 1 set |

| 9 | Conveyor | 1 set |

| 10 | Stacker | 1 unit |

| 11 | Hydraulic System | 1 set |

| 12 | Electrical System | 1 set |

| 13 | Pneumatic System | 1 set |

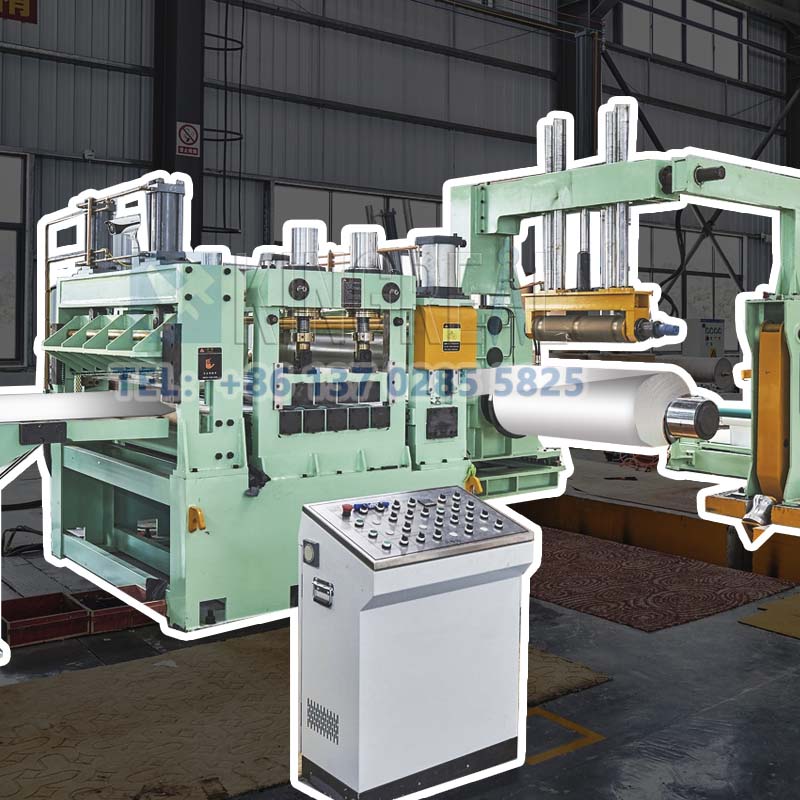

Coil Blanking Cut To Length Component Details

1. Hydraulic Coil Car

The trolley can move horizontally and vertically, which is convenient for the steel coil to be put into the uncoiler in the cut to length line.

Vertical hydraulic drive, horizontal movement is driven by XWD1.5-63-121 cycloid motor.

Equipped with a four-guide column hydraulic cylinder, stable and safe.

2. Hydraulic Uncoiler

Supports steel coil and uncoiling for the cut to length machine.

The iron core can guarantee the expansion range of the inner diameter of the coil φ508.

Using a hydraulic oil cylinder to make the uncoiler retractable and fit the inner diameter of the coil. It is equipped with a cantilever.

The 7.5KW motor drives the coil to run, it can run forward and reverse, and it can also be tension and uncoiled.

3. Leveler with Hold Down Device

The inlet is equipped with a clamping device, which is hydraulically driven.

It consists of 19 leveling rollers, 2 sets of idler rollers, driving device, 2 pinch rollers, and frame. Both sides of each roller are driven by pin pins, which are the main rollers. The total number of rollers is 21, the diameter is 65mm, the distance between the rollers is 70mm, and the rollers are supported. All rollers are plated to protect the stainless steel surface from abrasion.

The role of the idler is to balance the force of the leveling roller and reduce the friction to the roller.

The gap of the work roller can be adjusted electrically and controlled by 2 hand-wheels to ensure the leveling quality.

Drive mode: All independent drums and gearboxes are driven by 30Kw variable frequency speed regulation motors.

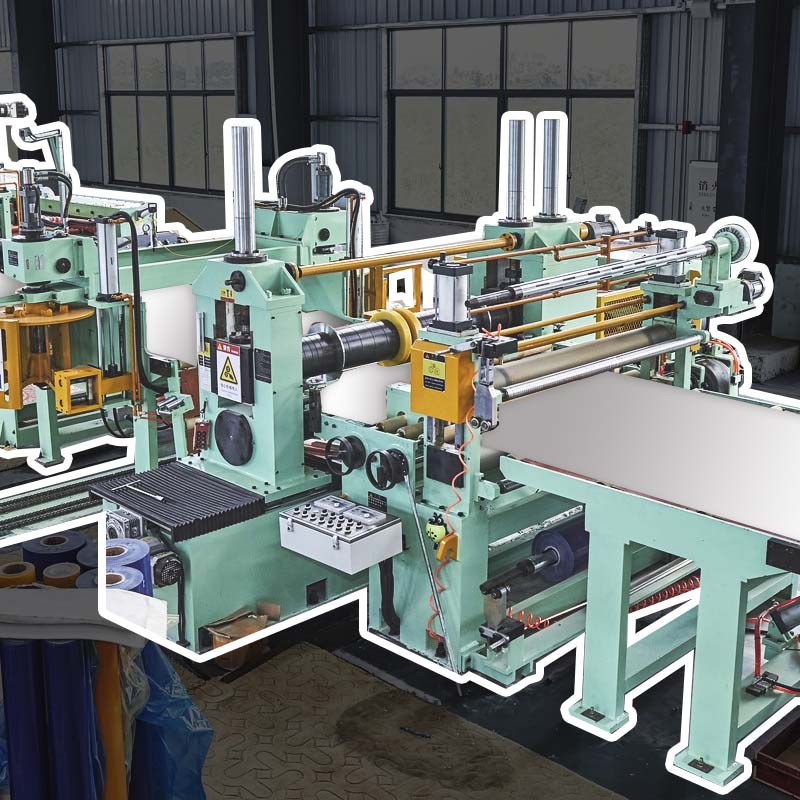

4. Loop

Using 2 sets of magic eyes to control the speed buffer between the straightening machine and the servo precision straightening machine.

The magic eye is controlled by PLC in the blanking line.

5. Side Guide Device

Using vertical rollers on both sides to guide the strip to the straightening device and the slitting machine.

The rollers on both sides are adjusted by the lead screw. The width range is 300-1300mm.

6. Servo Precision Straightening Machine

Four conveying fixed-length rollers, tempered rollers are coated on the surface of polyurethane and finely ground.

Controlled by a servo motor for adjustment of high-speed feed and precise length control.

The operation is carried out on the console, with programmable control.

Drive mode: 11Kw servo motor, precision deceleration drive, synchronously conveying the belt to the feeding roller.

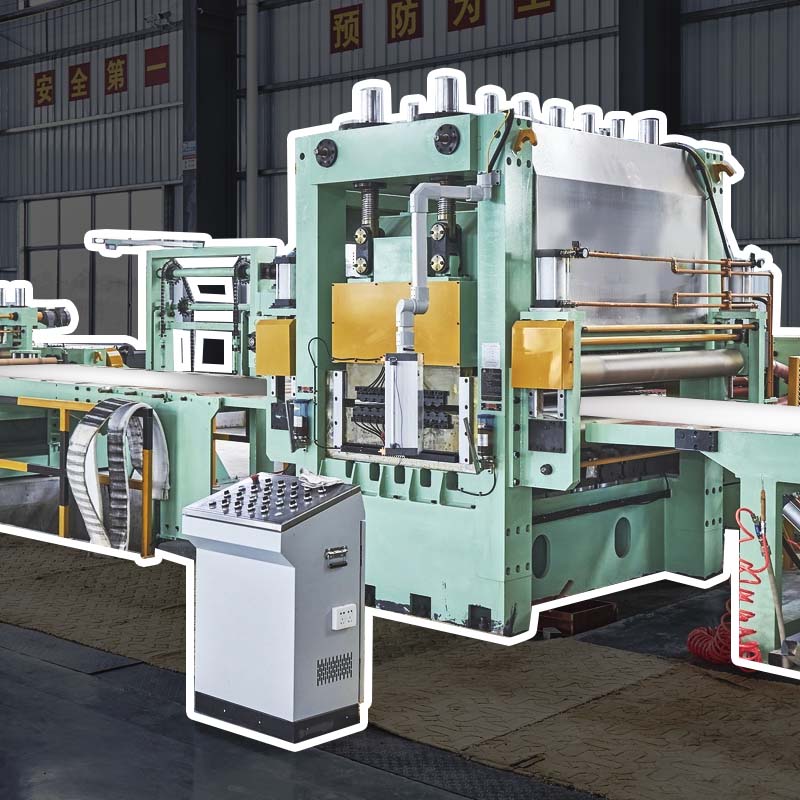

7. High-Speed Shearing Machine

Shearing type: hydraulic shearing from bottom to top.

PLC control to realize automatic cutting.

With the direct signal of the feeder, automatic cutting.

Adopt the gap adjustment design, cut the material, and can safely cut 4mm steel plate after heat treatment.

Blade material: 6CrW2Si.

Advantage Of Blanking Line Cut To Length

1.The Cut to length line is capable of handling a wide range of different metal coils, including stainless steel, iron, aluminum, tinplate and more!

2.Cut to length machine has a proprietary feed roll design on the leveling device and feed guide device for non-marking surface critical materials, surface treatment.

3.Cut to length production line can be designed with flying shear system to achieve high speed and high precision shearing effect of 80M/min.

4. The Cut to Length Line (CTL) is renowned for its exceptional length precision, which surpasses industry standards. Utilizing high-precision servo motors and programmable logic controllers (PLC), the CTL line ensures that each cut is executed with unparalleled accuracy.

5. One of the standout features of the Cut to Length Line (CTL) is its highly efficient coil loading and packaging removal system. The CTL line utilizes advanced hydraulic coil cars and automated uncoiler that streamline the loading process, allowing for quick and safe handling of steel coils.

6. The automated packaging removal system ensures that spent coils are swiftly and efficiently removed from the production line, reducing downtime and maintaining a steady workflow.

7. The Cut to Length Line (CTL) boasts a state-of-the-art control system equipped with a highly efficient and user-friendly operator interface. This advanced control system integrates the latest in automation technology, enabling seamless and precise control over the entire production process.

FAQ: How to Achieve High Precision Cutting?

Cut to length machine use of 6 sets straightening rollers can effectively straighten high-rigidity metal materials and improve the straightening accuracy and feeding accuracy of materials. According to the optional requirements of customers, through the control of the servo system, the leveling range is automatically adjusted and the degree of automation is higher.

The blade of the cut to length line machine is chrome-plated, with high precision and more durability.

1. Different Thickness Slitting Line Light Gauge Steel Coil Slitting Line Medium Gauge Metal Slitting Machine Heavy Duty Coil Slitting Lines 2. Different Materials Slitting Line Stainless Steel Slitting Lines Silicon Coil Slitting Lines 3. Different Configurations Coil Slitting Machine Dual Slitter Head Coil Slitting Line Belt Tension Coil Slitting Machine

Please send us the following requirements and we will contact you as soon as possible to create a new quotation program for you - Coil Material - Coil Thickness - Coil Width - Coil Weight - Slit Width - Slit Speed

1. Decoiler Machine 2. Dual Slitter Head 3. Belt Tension Station 4. Auto Package Lin For The Slit Coil