"Simply coil slitting machines are mostly used to split coils lengthwise into demanded widths, particularly appropriate for little production or those just starting in the metalworking sector are these fully automated, compact, and affordable machines. Simply slitting lines are growing increasingly popular among many companies because of their effective manufacturing capacity and broad application range as the metallurgy business develops quickly.This article will provide a detailed introduction to the simply coil slitting machine's operating principle, main components, and technical specifications to help you better understand this simply slitting line."

▏How Simply Coil Slitting Machine Works?

The simply coil slitting machine's operating principle is relatively simple yet highly effective. First, the coil is unwound by a hydraulic decoiler and secured to the machine. Next, the blades of the simply slitting line slit the coil lengthwise. Before being reeled by a recoiler, the finished strip is stabilised by a tension frame following slashing. The whole process is automated, hence greatly increasing production efficiency.

The design of the simply coil slitting machine allows operators to simply manage the manufacturing process, so guaranteeing accuracy at every level. Particularly for small and medium-sized companies with limited finances and space, the simply slitting line's high degree of automation and small footprint make it an excellent fit.

▏Main Components of Simply Coil Slitting Machine

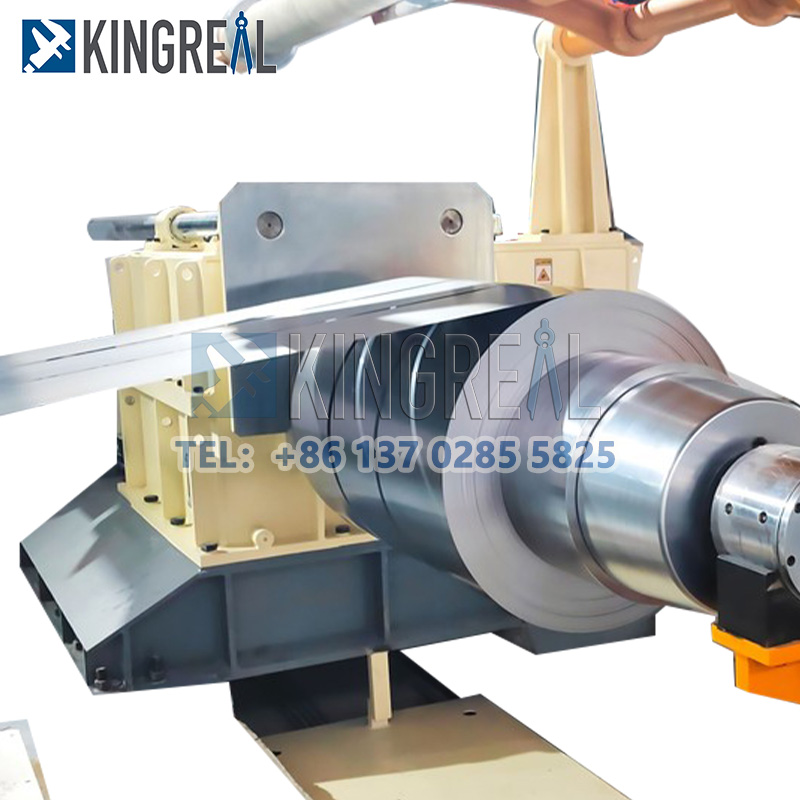

1. Hydraulic decoiler for simply slitting line

Mostly employed to tighten the inner diameter of the steel coil to preserve coil stability, the hydraulic decoiler is the first crucial component of the simply coil slitting machine.

Steel coils with an inner diameter of Ø480-520 mm and width of 500 mm can be decoiled using this hydraulically driven apparatus. It is intended to support ten tons and features a basic bracket for easy maintenance and installation. By means of a hydraulic mechanism, the hydraulic decoiler firmly connects the coil to the active decoiler, therefore preventing it from loosening during the slitting operation. It also features a brake to prevent the coil from accidentally sliding during processing.

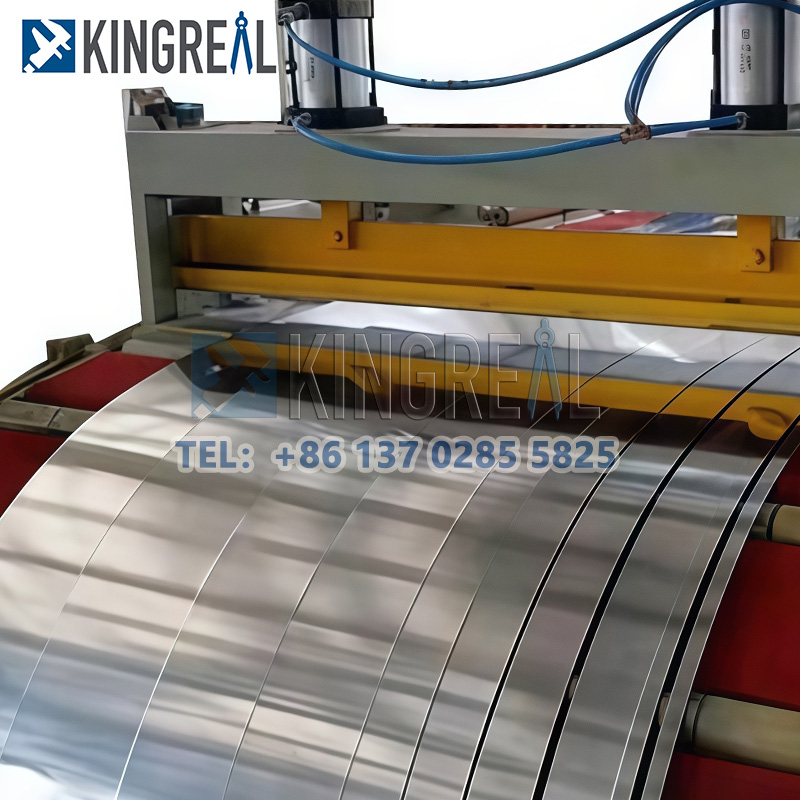

2. Main slitter for simply slitting line

The main slitter is the core component of the simply coil slitting machine, responsible for precisely slitting the coil.

The slitter blade has a diameter of Ø340x200x15 and is made of Cr12 material, offering excellent wear resistance and cutting performance. And the motor is 7.5kW variable-frequency speed-controlled motor allows for adjustable speed, ensuring flexible and adaptable slitting. Variable-frequency speed control allows for adjustment to varying strip thicknesses and production requirements. Equipped with a cycloidal pinwheel reducer, it ensures stable output power and cutting accuracy. The simply slitting line is also equipped with side guides, which ensure precise strip positioning, prevent strip skipping, improve slitting accuracy, and guarantee the quality of the finished product.

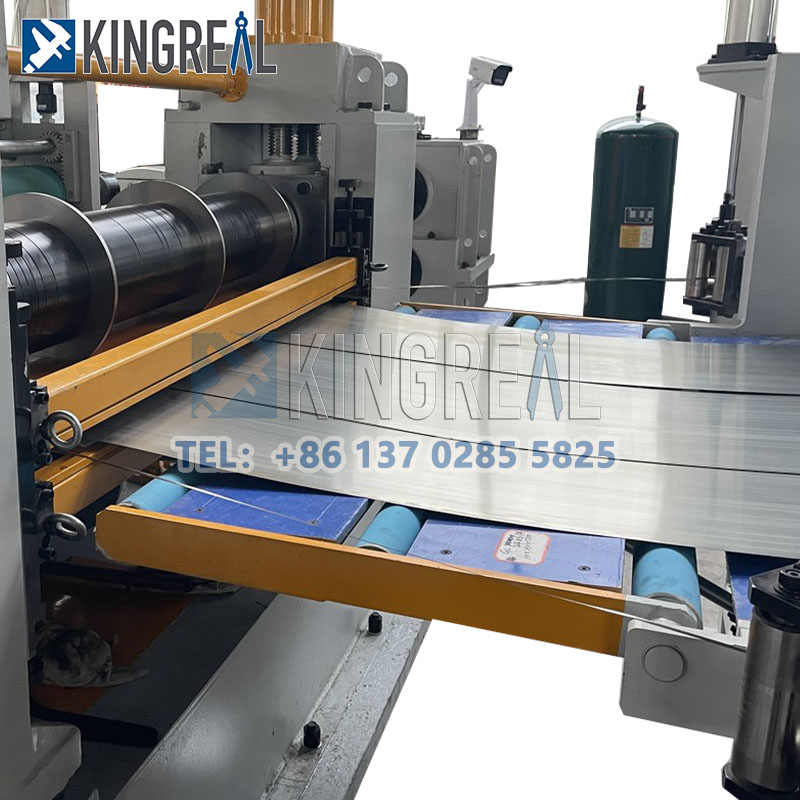

3. Tension frame for simply coil slitting machine

The tension frame plays a vital role in the simply slitting line, maintaining strip tension and stability.

The frame is constructed of welded steel plates, ensuring high strength and durability. And It consists of a base, pre-indexing shaft, bracket, hold-down shaft, hydraulic damping device, and hydraulic lift/hold-down mechanism, ensuring uniform tension distribution.

The tension frame is equipped with side guides for the finished strip, effectively preventing strip skipping during coiling, thereby improving coiling quality. It creates tension with the coiler, ensuring uniform and compact coil quality after coiling.

4. Reoiler for simply slitting line

The recoiler is the final stage of the simply coil slitting machine, responsible for coiling the slit strip.

The recoiler features a hydraulically retractable design, capable of supporting a load of 10 tons, and is equipped with a simple stand for easy operation. A 7.5kW motor is also used, ensuring stability and efficiency during the coiling process. The recoiler is used to coil finished strip after primary and secondary indexing, ensuring uniform and compact coil quality. The coiling tension and speed are adjustable to suit different production needs.

▏Technical Parameters of Simply Slitting Line

| Item | Parameters |

Coil thickness(mm) | 0.4-1 |

Max speed (m/min) | 20 |

No. of slitters | Tailor-made |

| Roll stand | 18 |

| Main power (Kw) | 7.5 |

Main shaft (mm) | Ф70 |

Cutter material | Cr12 |

Cutting accuracy | 10±2mm |

Hydraulic station power (Kw) | 5.5 |

Control system | PLC |

▏Advantages of Simply Coil Slitting Machine

The simply slitting line offers numerous advantages, making it an ideal choice for small and medium-sized businesses and new entrants into the metalworking industry.

1. Small footprint simply coil slitting machine

The simply slitting line's compact design effectively conserves factory space. Space is often a significant constraint for small businesses or metalworking startups. The simply coil slitting machine's compact footprint allows for efficient production within limited space, helping businesses maximize every inch of available space.

2. Highly Automatic simply coil slitting machine

The simply slitting line's fully automated design makes operation simple, reducing operator skill requirements. The entire production process is managed by a PLC control system, enabling real-time monitoring and adjustment of every step, significantly improving production efficiency and reducing the risk of human error. This high level of automation enables companies to achieve high production output with minimal labor.

3. Affordable simply coil slitting machine

The simply slitting line is relatively affordable, making it suitable for companies with limited funds. Its high cost-effectiveness allows companies to acquire efficient production equipment with minimal investment, reducing production costs and improving economic benefits. This feature is particularly suitable for small companies entering the market, helping them quickly establish production capacity in the early stages.

4. Highly adaptable simply coil slitting machine

The simply slitting line can process a variety of coil types, including stainless steel, steel, PPGI, aluminum, copper, and other metal materials, offering exceptional adaptability. Regardless of the thickness or width of the metal, the simply coil slitting machine can flexibly accommodate diverse customer needs. This flexibility makes the simply slitting line suitable for a wide range of applications in various industries.

5. Easy maintenance simply coil slitting machine

The simply slitting line's rational structural design makes maintenance and upkeep relatively simple. In daily use, companies only need to regularly check the simply coil slitting machine's main components and hydraulic system to ensure proper operation. This feature effectively reduces maintenance costs and equipment downtime, ensuring continuous production.

7. Controllable quality for simply coil slitting machine

KINGREAL SLITTING has designed several quality control measures for the simply slitting line, such as side guides and tension racks, to ensure the quality and stability of the finished strip. These features enable companies to better control product quality during the production process, reduce rework and waste, and improve production efficiency.