In modern manufacturing, steel cut to length lines, as an important processing equipment, are widely used in the field of metal processing. With the continuous changes in market demand and technological advancement, steel ctl machines are also evolving.

This article will explore the purpose and market demand of steel cut to length machines, the importance of technological innovation, and KINGREAL SLITTING's specific measures in the technological innovation of steel cut to length line machines.

1. Purpose and market demand of steel cut to length equipment

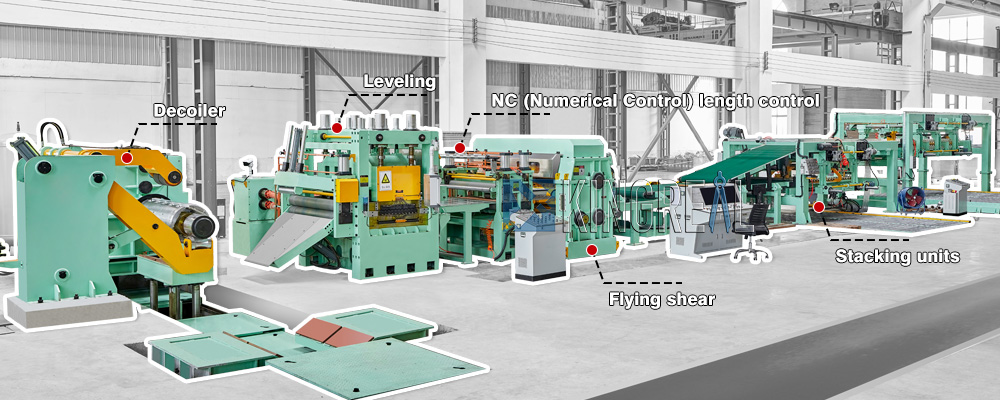

Steel cut to length lines are mainly used to shear metal coils or plates according to certain sizes and shapes. They are widely used in automobile manufacturing, construction, home appliances, electronic equipment and other manufacturing industries. With the continuous development of global industry, the market demand for steel ctl machines is also rising, which is specifically reflected in the following aspects:

1.1 Increased demand for industrial automation

With the advancement of industrial automation, enterprises have an increasing demand for high-efficiency and high-precision shearing equipment. Modern steel cut to length machines not only need to have basic shearing functions, but also need to realize automatic control to improve production efficiency and reduce labor costs.

1.2 Diversified material requirements

Different industries have diversified demands for metal materials, and companies need steel cut to length line machines that can handle a variety of metal materials. For example, the demand for lightweight materials in the automotive manufacturing industry has prompted steel cut to length line machines to be able to handle new metal materials such as aluminum alloys.

1.3 Increased precision and quality requirements

Customers have increasingly higher requirements for product quality and precision, which has driven the technological upgrading of steel cut to length equipment. High-precision shearing can reduce waste, improve material utilization, and reduce production costs.

1.4 Environmental protection and sustainable development

With the increase in environmental awareness, companies have also begun to pay attention to energy consumption and environmental performance in steel cut to length machine selection. Efficient steel ctl machines can not only improve production efficiency, but also reduce energy consumption and material waste.

2. Importance of technological innovation in steel cut to length machines

In a highly competitive market environment, technological innovation has become a key factor in the survival and development of enterprises. For steel cut to length machine manufacturers, the importance of technological innovation is reflected in the following aspects:

2.1 Enhance market competitiveness

Through technological innovation, manufacturers can provide more efficient and accurate steel cut to length equipment products to meet the diverse needs of customers. This capability not only enhances the company's market competitiveness, but also establishes a good brand image in the industry.

2.2 Improve production efficiency

Innovative shearing technology and automated control systems can significantly improve production efficiency and reduce production cycles. For manufacturing companies, shortening production time means being able to respond to market demand more quickly and improve customer satisfaction.

2.3 Reduce production costs

Through technological innovation, companies can optimize production processes, reduce material waste and energy consumption, and thus effectively reduce production costs. This gives companies an advantage in price competition.

2.4 Promote sustainable development

With increasingly stringent environmental regulations, manufacturers need to improve the environmental performance of steel cut to length machine and reduce the impact on the environment through technological innovation. Innovative steel ctl machines can achieve efficient and low-energy production, which meets the requirements of sustainable development.

3. KINGREAL SLITTING's steel cut to length line machine technology innovation

As a leading manufacturer in the steel cut to length equipment industry, KINGREAL SLITTING has always been committed to technological innovation and continuously launched high-performance steel cut to length machines that meet market demand. The following are several important measures taken by KINGREAL SLITTING in the technical innovation of steel ctl machines:

3.1 Different metal coil thicknesses

KINGREAL SLITTING has launched light gauge, medium gauge and heavy gauge steel cut to length lines according to the different needs of customers, which are suitable for metal raw materials of different thicknesses:

- Light gauge steel cut to length equipment: can handle metal plates with a thickness of 0.3-3mm, suitable for the shearing needs of light materials.

- Medium gauge steel cut to length equipment: can handle metal plates with a thickness of 0.3-6mm, suitable for the production of medium-thick materials.

- Heavy gauge steel cut to length equipment: can handle metal plates with a thickness of 6-20mm. This technology is relatively rare in the market and can meet the needs of heavy industry.

It is worth mentioning that the manufacturing of heavy gauge steel ctl machine not only has higher requirements on the raw materials and processes of the steel cut to length line machine, but also provides customers with more targeted options, ensuring the flexibility and adaptability of customers when choosing steel cut to length line machine.

3.2 Different metal raw materials

KINGREAL SLITTING's steel cut to length machine can handle a variety of metal materials, including:

- Cold rolled steel coil

- Hot rolled steel coil

- Galvanized steel coil

- Silicon steel coil

- Stainless steel coil

- Aluminum coil

This diverse processing capability enables KINGREAL SLITTING's steel cut to length line machine to meet the needs of different industries and customers, especially in the automotive, home appliance and construction industries, which can effectively improve production efficiency.

3.3 Different shearing methods

In order to meet the different production needs of customers, KINGREAL SLITTING provides steel ctl machines with three different shearing methods:

1. Fixed shearing steel ctl machine: suitable for small-scale production and customers who do not have high production requirements. Fixed shearing steel cut to length line machine is simple and easy to use, suitable for start-ups or small workshops.

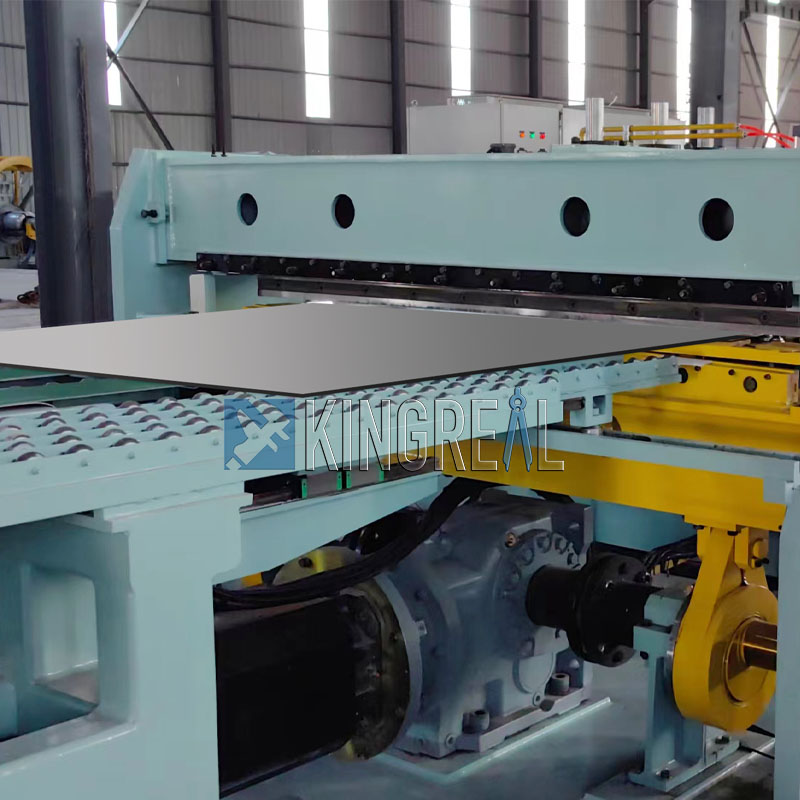

2. Flying shear steel ctl machine: KINGREAL SLITTING's flying shear steel ctl machine can accelerate the steel ctl machine and synchronize it with the narrow strip speed, cutting different materials without stopping feeding. This technology greatly improves production efficiency and is suitable for large-scale production.

3. Swing shear steel ctl machine: Through the customized design of the steel cut to length machine, continuous swing cutting without stopping during the production process is successfully realized. Compared with ordinary steel cut to length equipment, this swing shear steel ctl machine can cut metal plates (such as trapezoidal metal plates) without specifications, thus meeting most of the needs of automobile parts manufacturing.

This diversified shearing method not only improves the applicability of the product, but also provides customers with more flexible production solutions.