Cold rolled slitting lines are widely used in the sheet metal processing industry. They are used to cut cold rolled coils longitudinally according to the specific size required by customers, and then rewind them into narrow strips. The products can be used for rolling, welding pipes, cold bending, stamping, etc. With the increasing market demand for efficient production and high-quality products, traditional cold rolled slitting machines face challenges such as low efficiency, high labor costs and poor product consistency. Therefore, a new generation of fully automatic cold rolled slitting line manufacturing solutions came into being. The new generation of cold rolled slitting machines adopts advanced automation technology to realize the intelligent production process and greatly reduce the need for human intervention. In this article, KINGREAL SLITTING will discuss with you the working principle of cold rolled slitting lines, the advantages of the new generation of fully automatic solutions, and successful cases, aiming to provide comprehensive reference and inspiration for industry practitioners. |  |

Working Principle of Cold Rolled Slitting Line

1. Unwinding part for cold rolled slitting machine -The metal sheet coil is placed on the decoiler, and the decoiler is driven by a motor so that the sheet coil can be released smoothly at a certain speed. Generally, the decoiler is equipped with a tension control system to ensure that the sheet maintains proper tension during the unwinding process and avoids the sheet from being loosened or overly tight. For example, devices such as magnetic powder brakes are used to control the tension, and the appropriate tension value is adjusted according to factors such as the material, thickness and slitting speed of the sheet. |  |

2. Guide device for cold rolled slitting line -The sheet released from the decoiler enters the guide device. The function of the guide device is to correct the running direction of the sheet and ensure that the sheet accurately enters the slitting tool part. It usually consists of guide rollers that can be fine-tuned in the horizontal and vertical directions to adapt to the deviation of the initial position of the sheet. If the sheet deviates during operation, the guide device can correct it back to the correct path in time. |  |

3. Slitting tool part for cold rolled slitting machine -Tool structure: The core of the cold rolled slitting line is the slitting tool, which is generally composed of two sets of upper and lower circular blades. The upper blade and the lower blade are staggered with each other, and the spacing between the blades is adjusted according to the required strip width. For example, to cut a metal sheet with a width of 1 meter into 5 strips with a width of 20 cm, it is necessary to accurately adjust the blade spacing to 20 cm. Cutting principle: When the sheet passes through the slitting cutter, the upper and lower blades rotate relative to each other, exerting shear force on the sheet. The motor drives the cutter to rotate, and the edges of the upper and lower blades move relative to each other at a very high speed, cutting the sheet into thousands of strips along the predetermined width like scissors. During the cutting process, factors such as the sharpness of the cutter, the gap between the cutters, and the speed of the cutter will affect the quality of the slitting, such as the flatness of the cut and the number of burrs. |  |

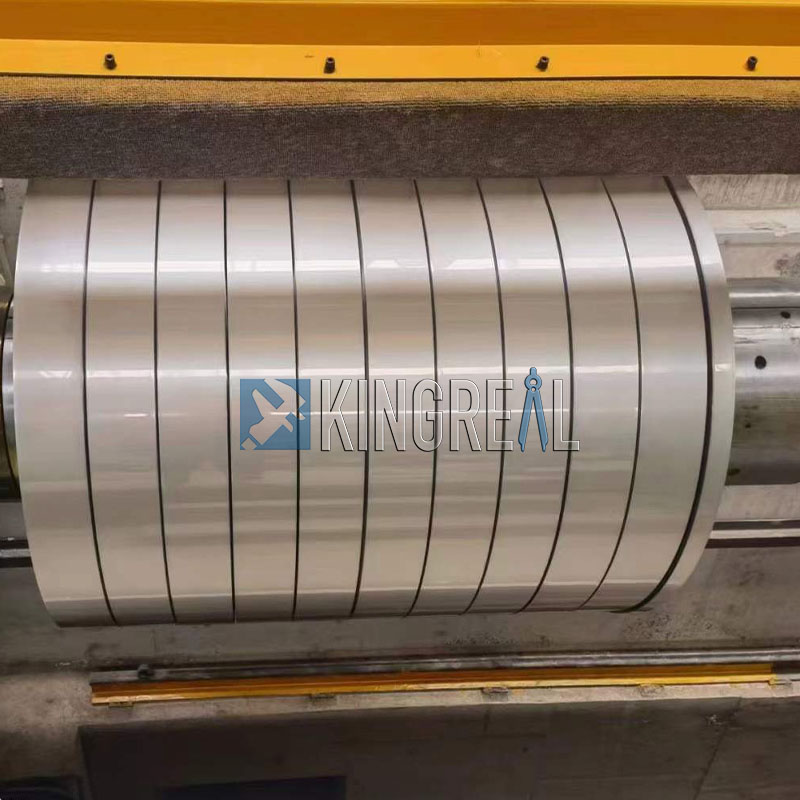

4. Rewinding section for cold rolled slitting machine -The metal strips after slitting enter their respective recoilers. The recoilers are also driven by motors to rewind the slitting metal strips into rolls. The recoilers are also equipped with tension control systems to ensure uniform tightness of the rewinding. The difference is that here, the tension needs to be independently controlled according to the specific situation of each metal strip after slitting to ensure the quality of each roll. For example, for thinner metal strips, less tension may be required to prevent the strips from being deformed or broken during the rewinding process. |  |

Advantages of New Generation of Cold Rolled Slitting Machine

KINGREAL SLITTING provides customers with cold rolled slitting line solutions with different configurations and parameters, which are designed to meet the specific needs of various industries. KINGREAL SLITTING can provide the following advantages in the cold rolled slitting machine manufacturing solutions: (1) Low-cost, low-speed cold rolled slitting lines are designed to meet the needs of internal slitting equipment for self-use only. (2) High-speed cold rolled slitting machines are equipped with all terminal and coil handling equipment, such as coil car buffer rollers, peeling tables and revolving doors, suitable for rolling mills and service centers. (3) Fully automatic cold rolled slitting lines are equipped with all hydraulic and pneumatic loading and unloading devices to minimize the number of tool changes and achieve high-speed production. Quick-change slitting heads minimize downtime for tool and gasket replacement. (4) Ensure uniform and tight winding without edge damage when slitting thin gauges and multiple strips. (5) The slitting head adopts a specially designed double eccentric/throttling design to achieve precise setting and burr-free slitting. The tensioner is specially designed to produce a tighter winding without damaging the surface. |  |

Successful Case of Cold Rolled Slitting Machine

As a professional cold rolled slitting line manufacturer with more than 20 years of experience, KINGREAL SLITTING has provided different cold rolled slitting machine solutions to customers in the United States, Albania, Ethiopia, the United Arab Emirates, Singapore and other countries. The featured cold rolled slitting line solutions include:

(1) Improving the surface quality of the slitting: KINGREAL SLITTING provides customers with cold rolled slitting machines equipped with laminating devices.

(2) Freeing up manpower: KINGREAL SLITTING provides customers with cold rolled slitting machines equipped with feeding trolleys.

(3) Improving efficiency: KINGREAL SLITTING provides customers with cold rolled slitting lines with a maximum speed of 230m/min.

(4) Improving safety: KINGREAL SLITTING provides customers with cold rolled slitting lines with protective covers.

KINGREAL SLITTING strives to provide customers with personalized cold rolled slitting machine manufacturing solutions. If you have special needs, please send your drawings and requirements to KINGREAL SLITTING!